Container forming device for filling machine

A molding device, filling machine technology, applied in the direction of packaging, multiple packages, transportation and packaging, etc., can solve the problems of inevitable pinching and rolling of cylindrical objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

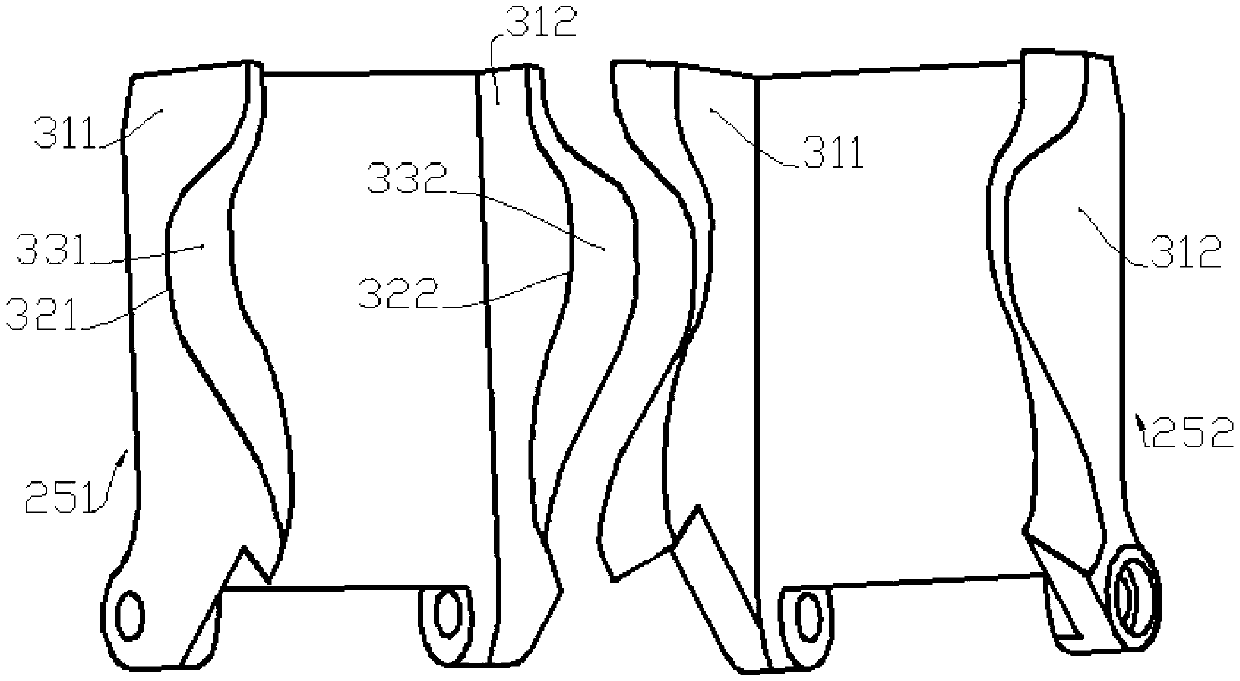

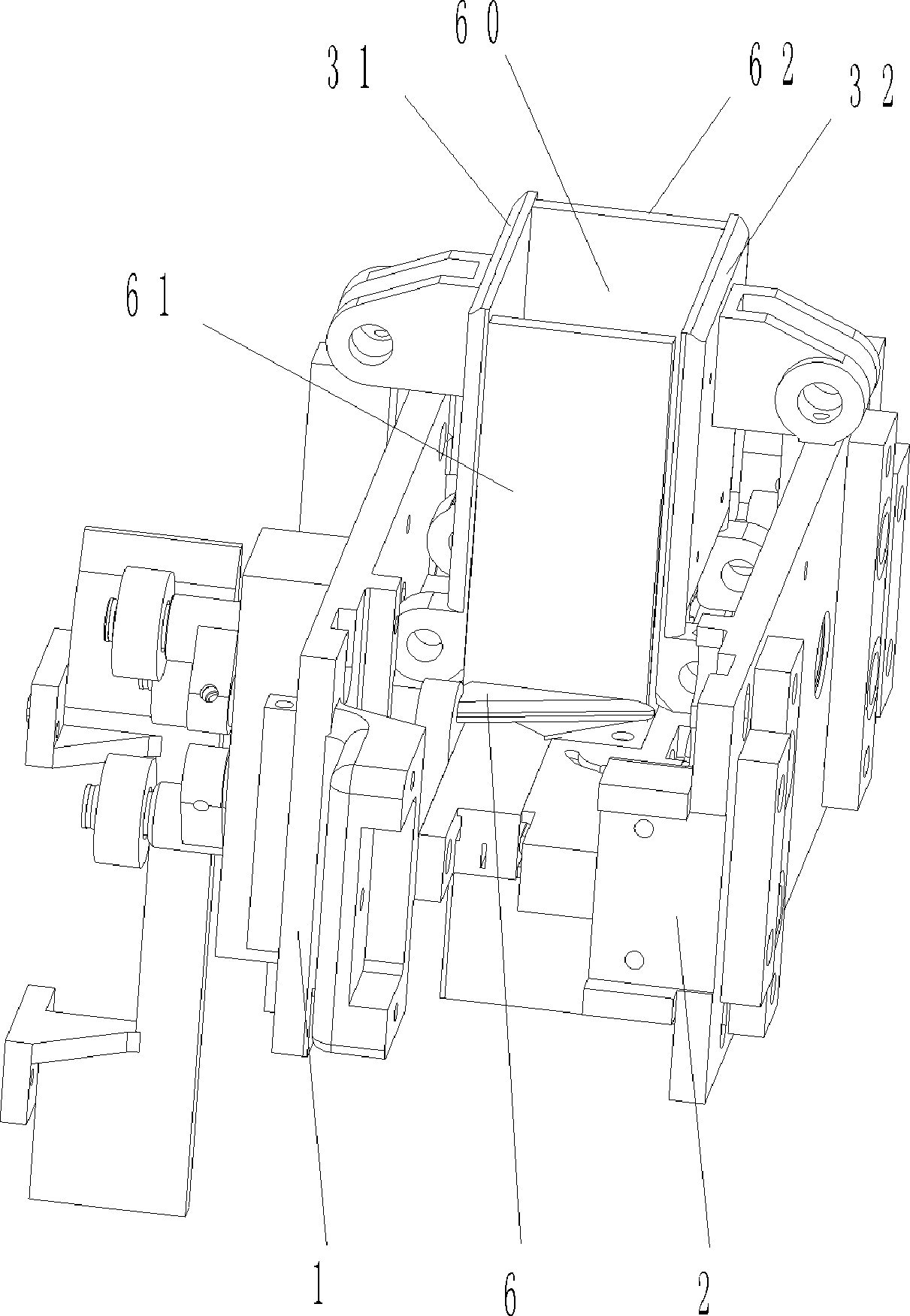

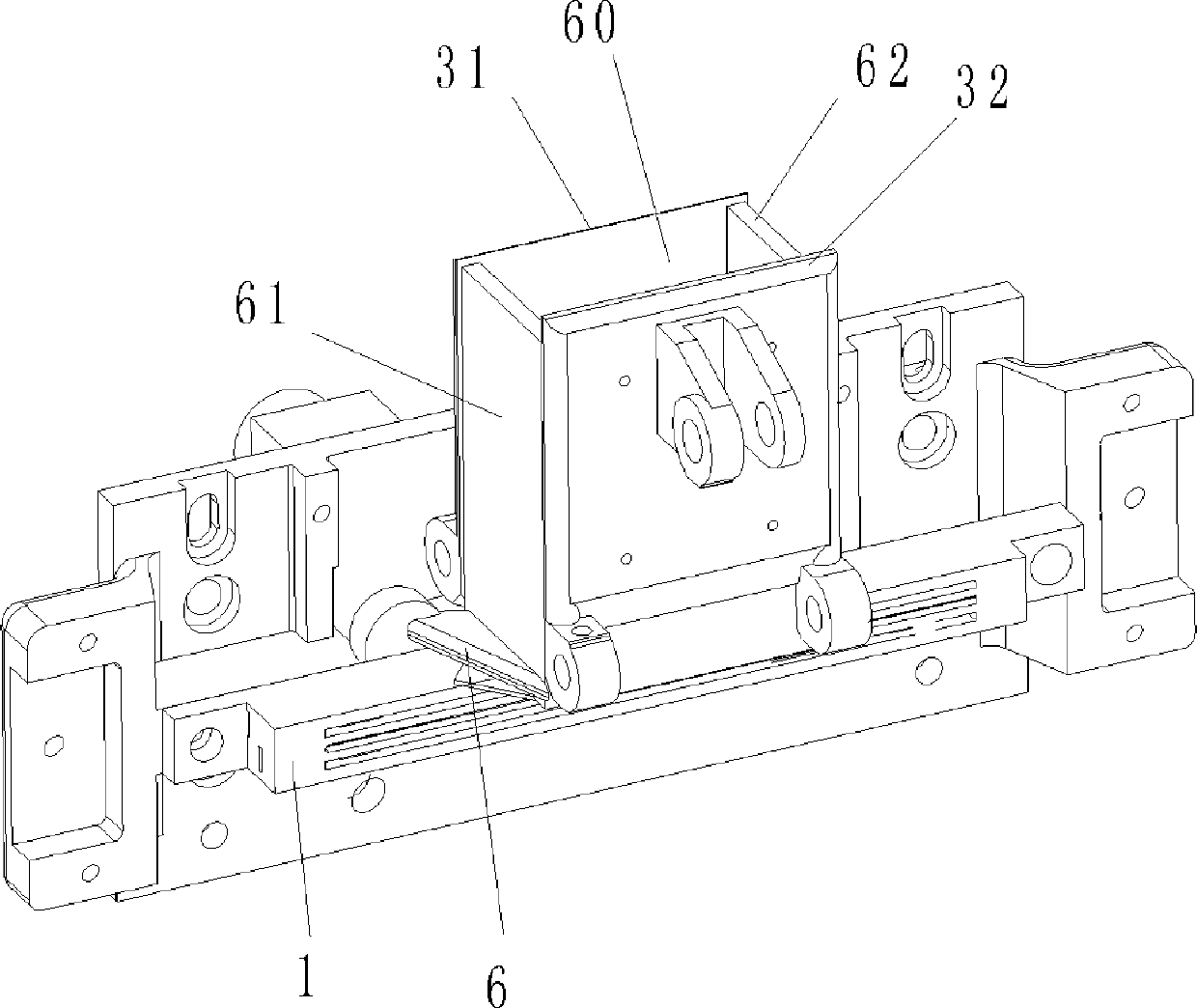

[0029] see Figure 2 to Figure 4 , is the first embodiment of a container forming device used in a filling machine according to the present invention, comprising capacity holders 31, 32 respectively arranged on the paired sealing jaws 1 and reverse sealing jaws 2, arranged on the sealing jaws Pair of movable members 6 on the jaws 1 for pulling the tube of packaging material.

[0030] The capacity holders 31, 32 are flat plates, which can hold the packaging container from both sides of the packaging container; the movable part 6 is detachably fixed with forming plates 61, 62; 6. When the packaging material tube is pulled, a molding cavity 60 with a rectangular cross-section surrounding the packaging material tube is formed with the capacity holders 31 and 32. The forming plates 61 and 62 are located between the two capacity holders 31 and 32. When the state of not pulling the packaging material tube, the forming plates 61, 62 are opened toward the two ends of the sealing jaw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com