Liquid injection air purification supercapacitor power supply system in vehicle

A supercapacitor, air purification technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as short circuits and affecting life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a supercapacitor power supply system for liquid injection and air purification inside a vehicle.

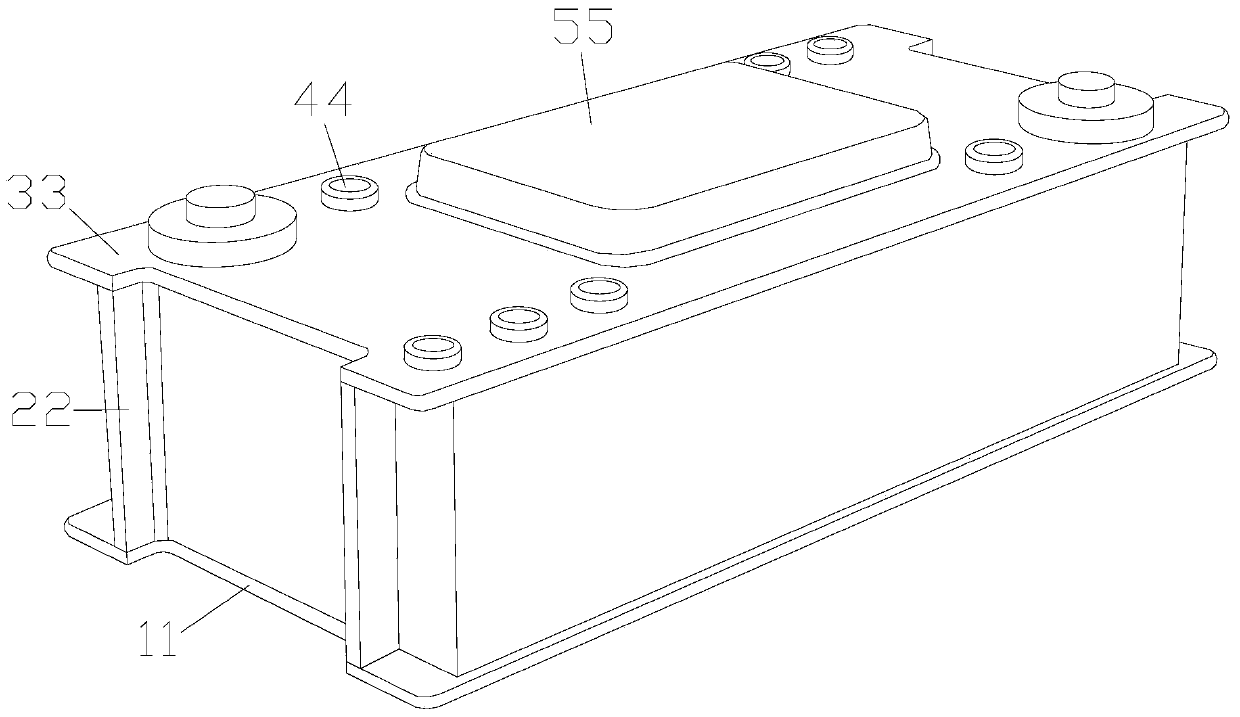

[0030] The upper surface of the bottom fixing plate 11 is connected to the lower surface of the capacitor grid 22, and the end of the capacitor grid 22 away from the bottom fixing plate 11 is connected to the top connection plate 33, and the hydraulic interface 44 penetrates inside the top connection plate 33 , the power terminal 55 is installed on the top of the top board 33 .

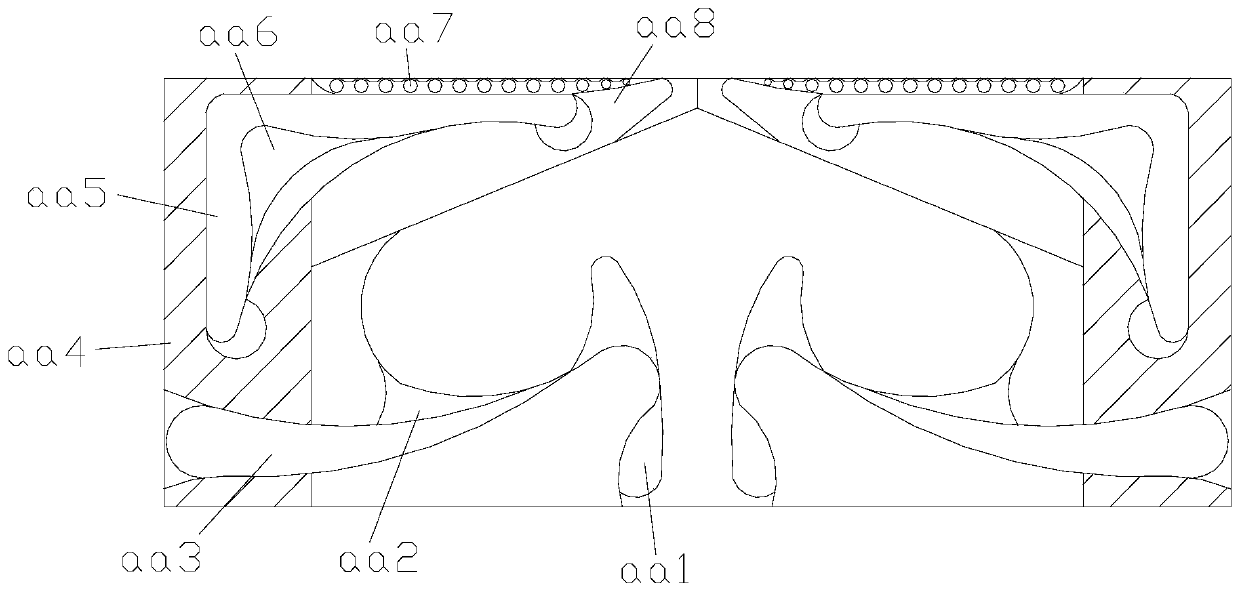

[0031] The hydraulic interface 44 includes suction arc disc aa1, curved clamping arc aa2, suction strip aa3, outer pocket layer aa4, clamping rod aa5, expansion arc opening aa6, top entry layer aa7, inner top layer aa8, and the curved clamping arc aa2 Attached to the outer surface of the suction strip aa3, the suction strip aa3 is connected to the suction arc plate aa1, the clamp rod aa5 is embedded inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com