Ratchet wrench

A ratchet wrench and accommodating groove technology, applied in the field of wrench tools, can solve problems such as sales obstruction, slow operation, and ring wear, and achieve the effects of improving operational sensitivity, reducing errors, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

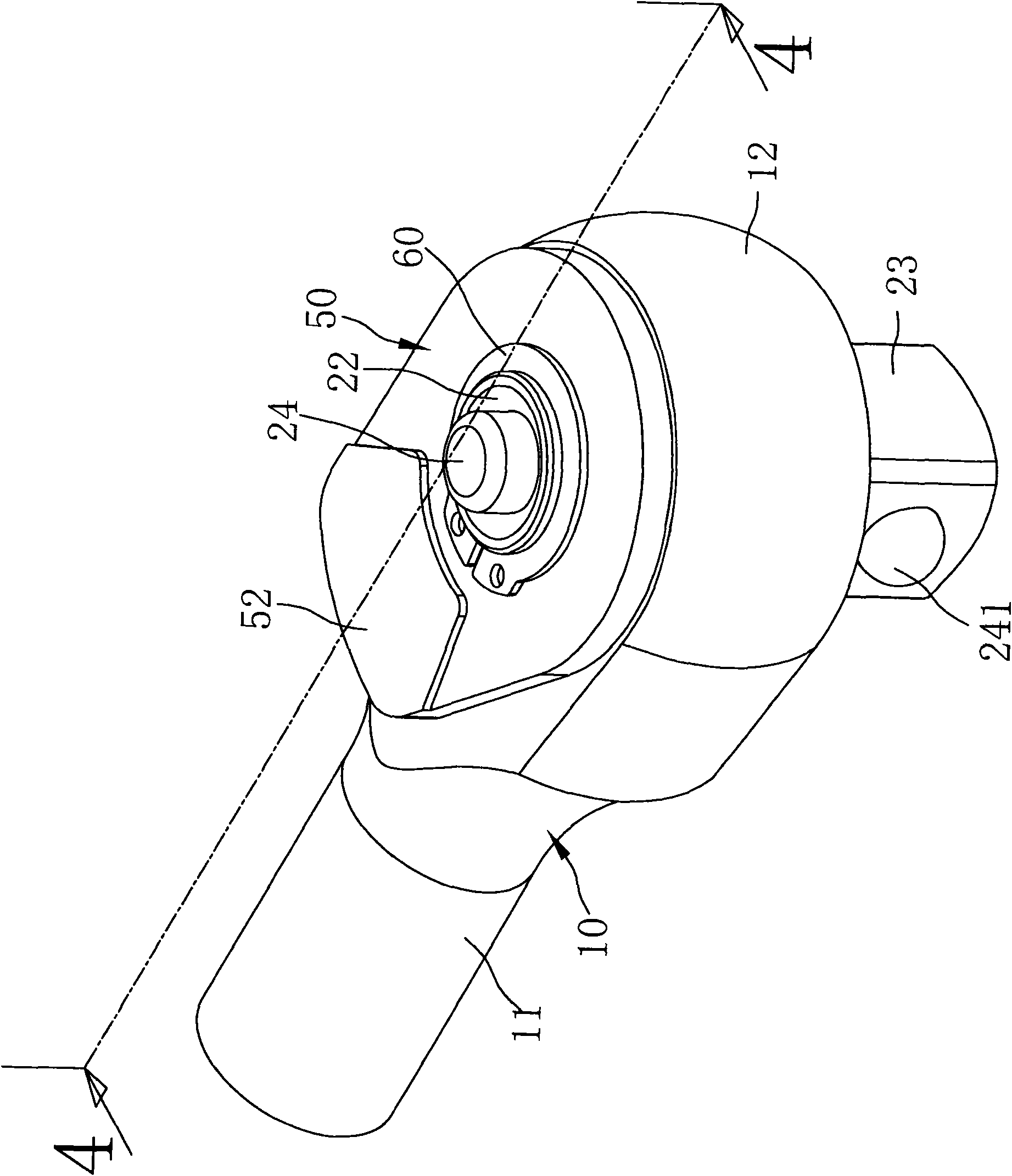

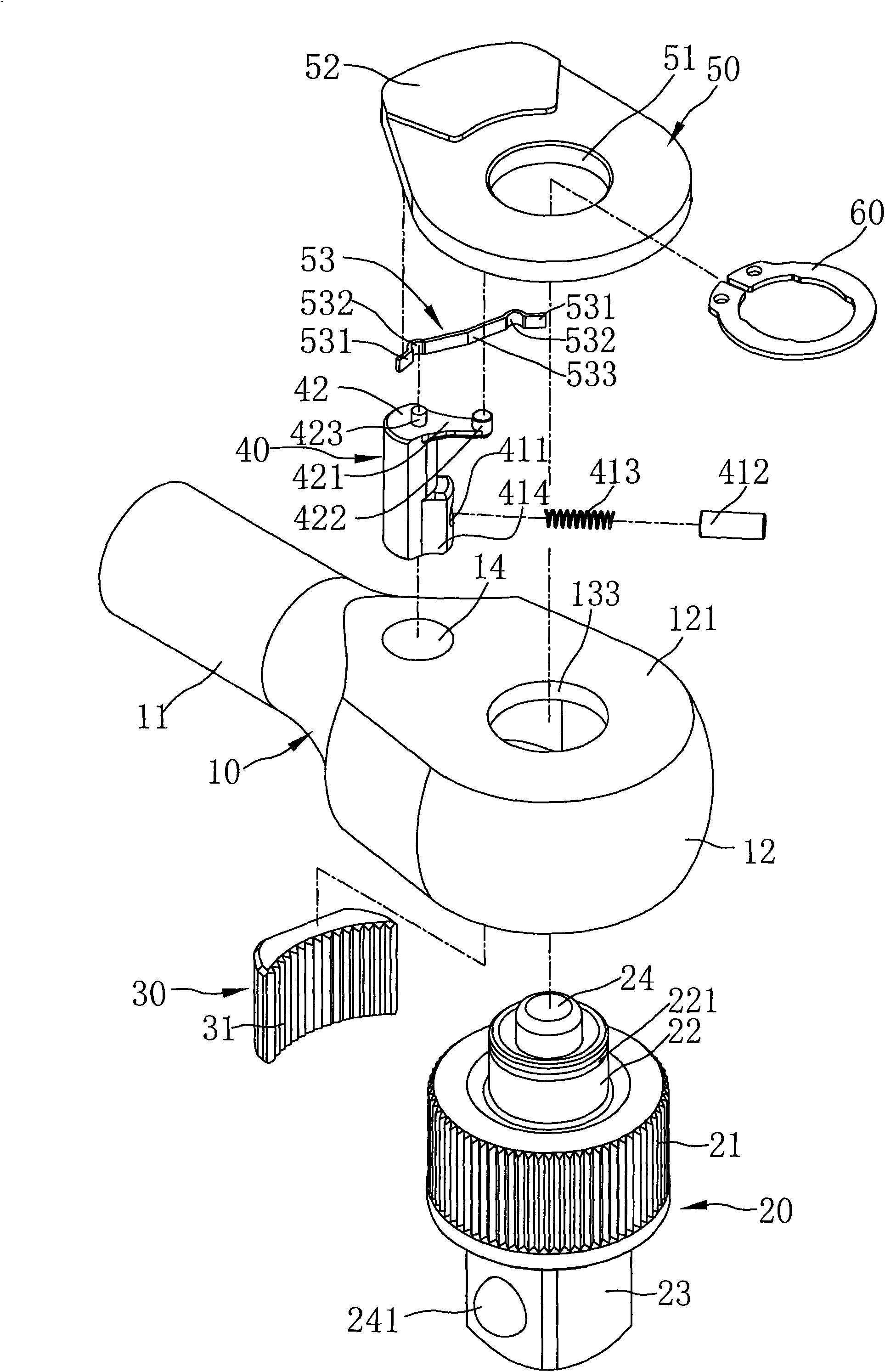

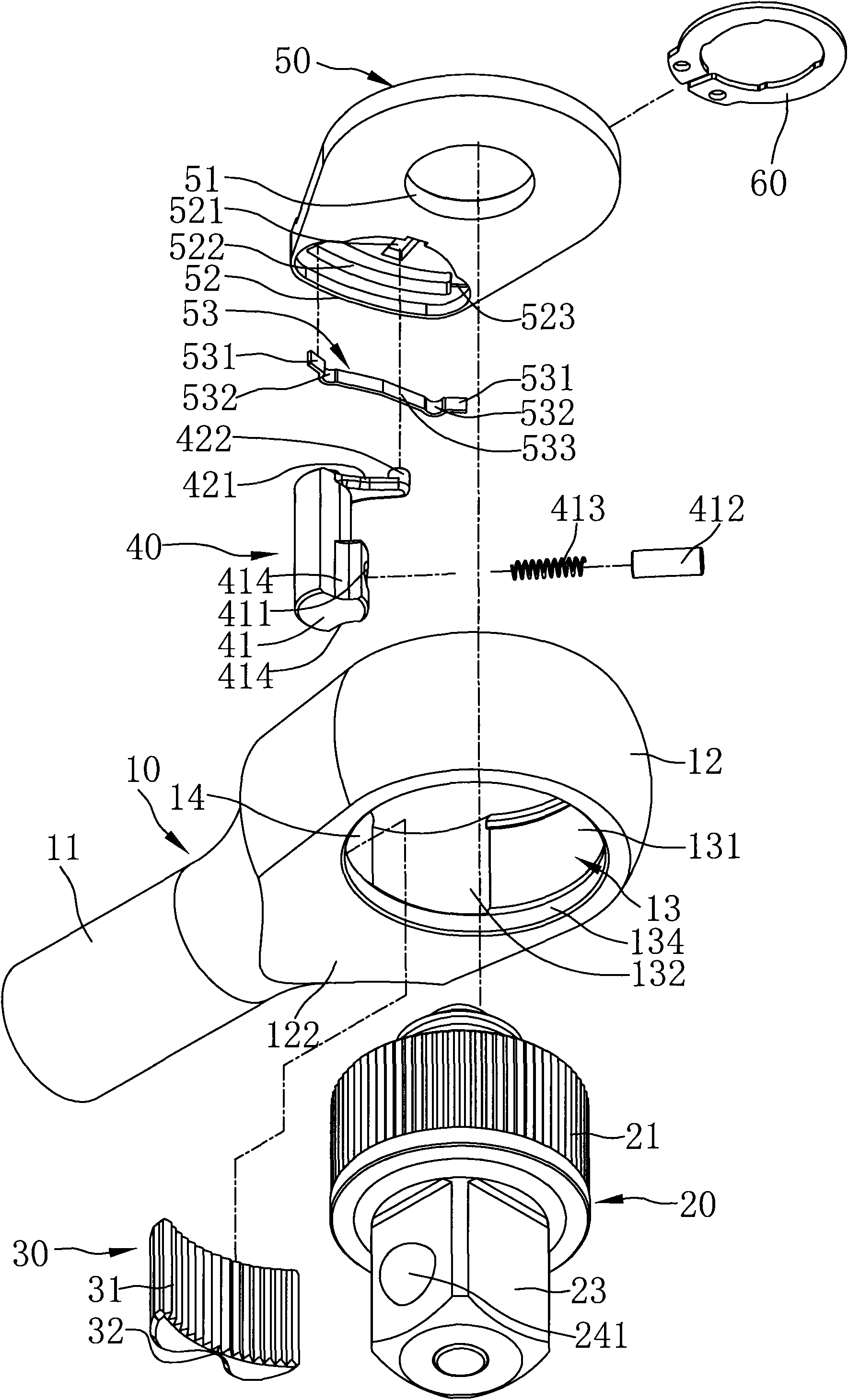

[0041] refer to figure 1 and figure 2 , the ratchet wrench of the present invention includes a body 10, a driving body 20, a locking block 30, a reversing switch 40 and a control member 50; wherein:

[0042] Please cooperate with the reference Figure 3 to Figure 4 , the body 10 includes a handle 11 and a head 12 connected to one end of the handle 11 . The handle 11 is for the user to hold, and a housing space 13 is formed in the head 12. The housing space 13 includes a circular first housing groove 131 and a concave groove formed by the inner wall of the first housing groove 131. The second accommodating groove 132 is in the shape of a crescent, and the second accommodating groove 132 communicates with the first accommodating groove 131 . When the main body 10 is operated by the user, it generally rotates around the axis of the first accommodating groove 131 in the head 12 as the rotation center.

[0043] The head 12 has a first plane 121 and a second plane 122 parallel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap