Urea-formaldehyde resin foaming and mixing device

A urea-formaldehyde resin and mixing device technology, applied in the field of mixing equipment, can solve the problems of unstable agronomic properties of urea-formaldehyde resin foam, low production efficiency, inconvenient operation, etc., and achieve the effect of high-efficiency agronomic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0014] The present invention adopts air bubbles as carriers, mixes urea-formaldehyde resin and air bubbles uniformly, makes the colloidal urea-formaldehyde resin adhere to the surface of air bubbles and solidifies, so as to obtain better urea-formaldehyde resin foam products.

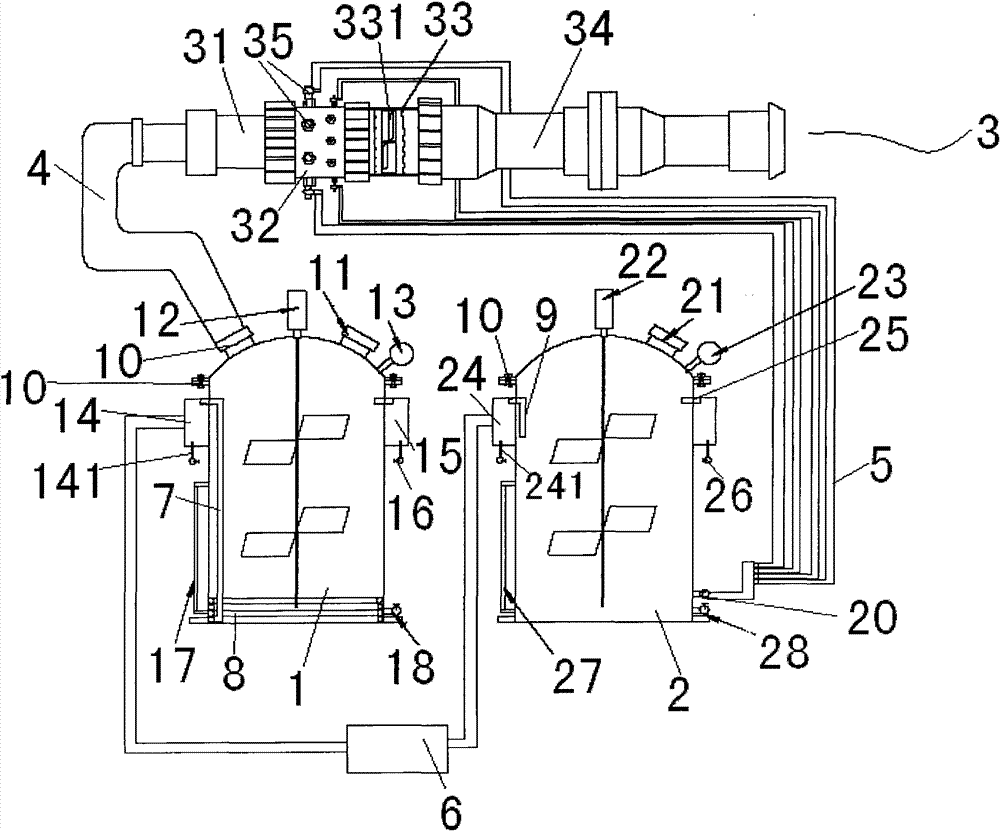

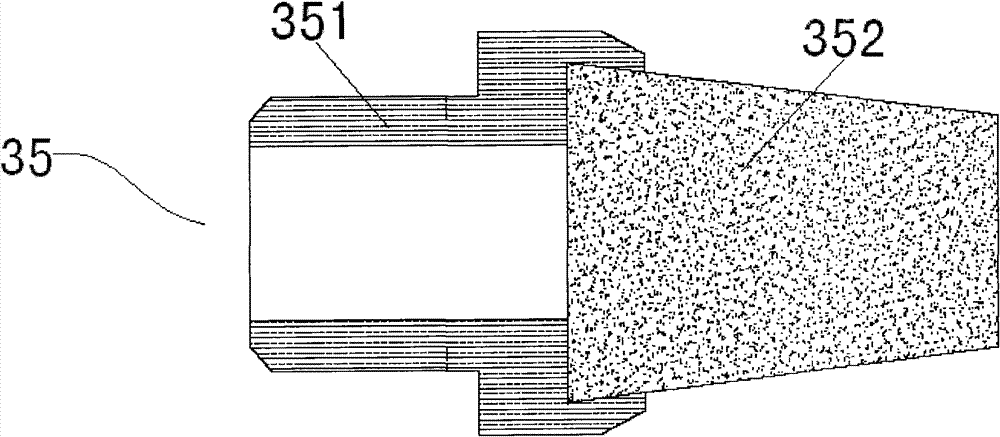

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a closed foaming tank 1 and a closed urea-formaldehyde resin tank 2 , and both the foaming tank 1 and the urea-formaldehyde resin tank 2 communicate with a mixing device 3 . In the mixing device 3 , a foam inlet cylinder 31 , a feed cylinder 32 , a mixing cylinder 33 and a discharge cylinder 34 are sequentially connected in series, and the two cylinders are connected by threads, which is easy to dismantle and easy to clean. The foam inlet cylinder 31 is connected to the foam outlet 10 on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com