A method of simulating and obtaining fault data of marine diesel engine

A marine diesel engine and fault data technology, which is applied in the direction of engine testing, machine/structural component testing, internal combustion engine testing, etc., can solve problems such as difficulties in data collection for specific fault states, and achieve the effect of ensuring random uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

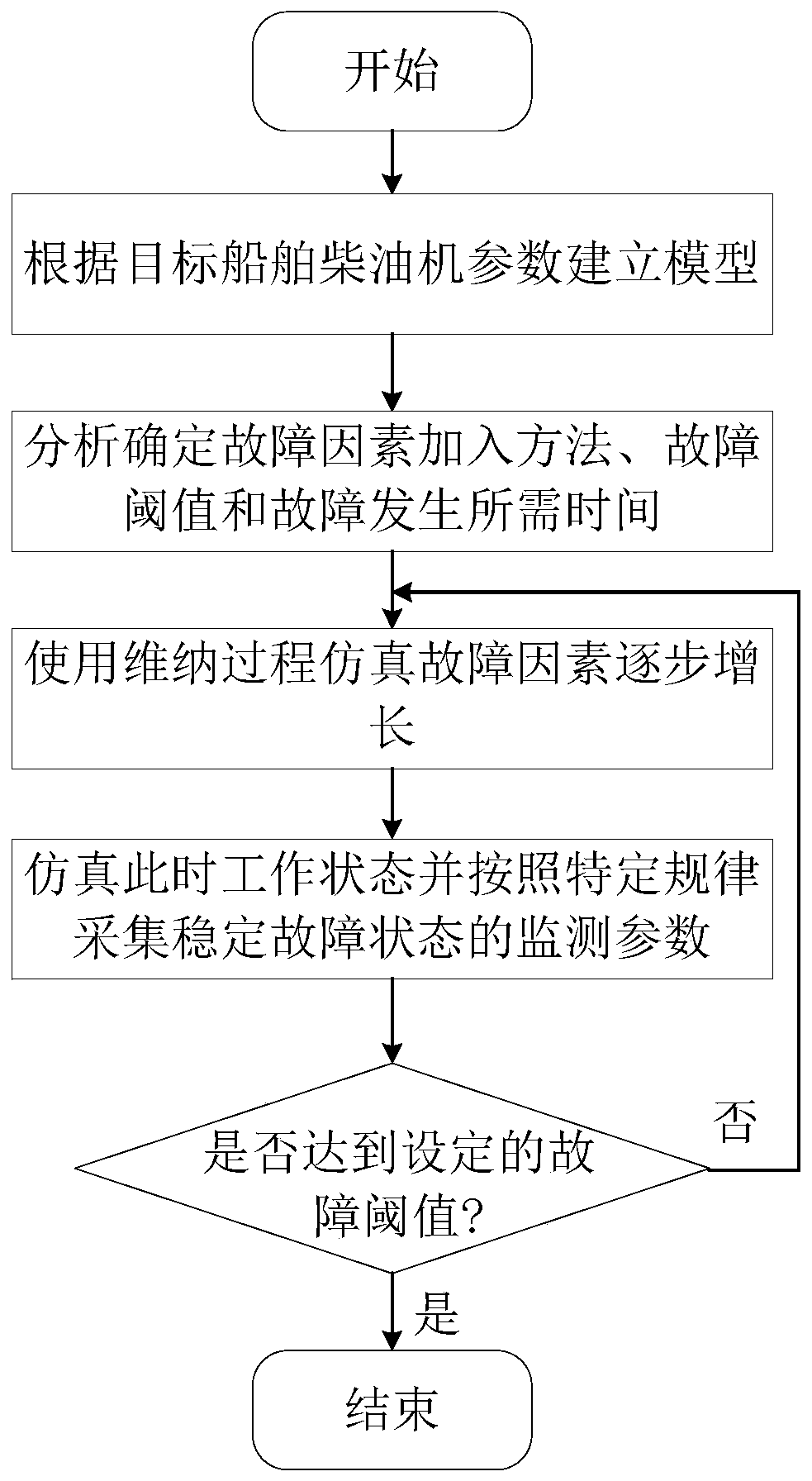

Method used

Image

Examples

Embodiment 1

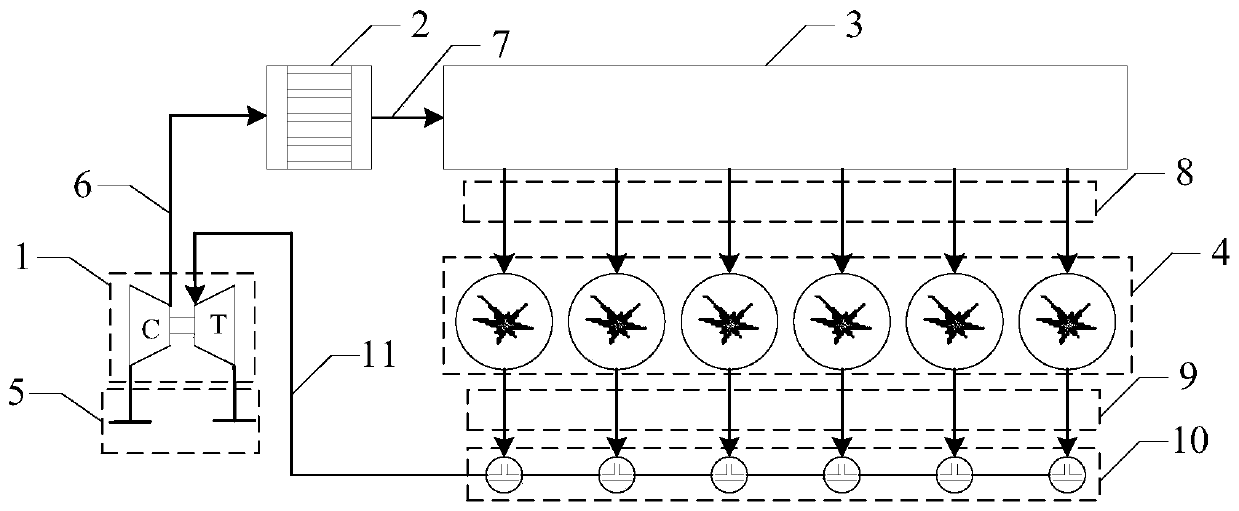

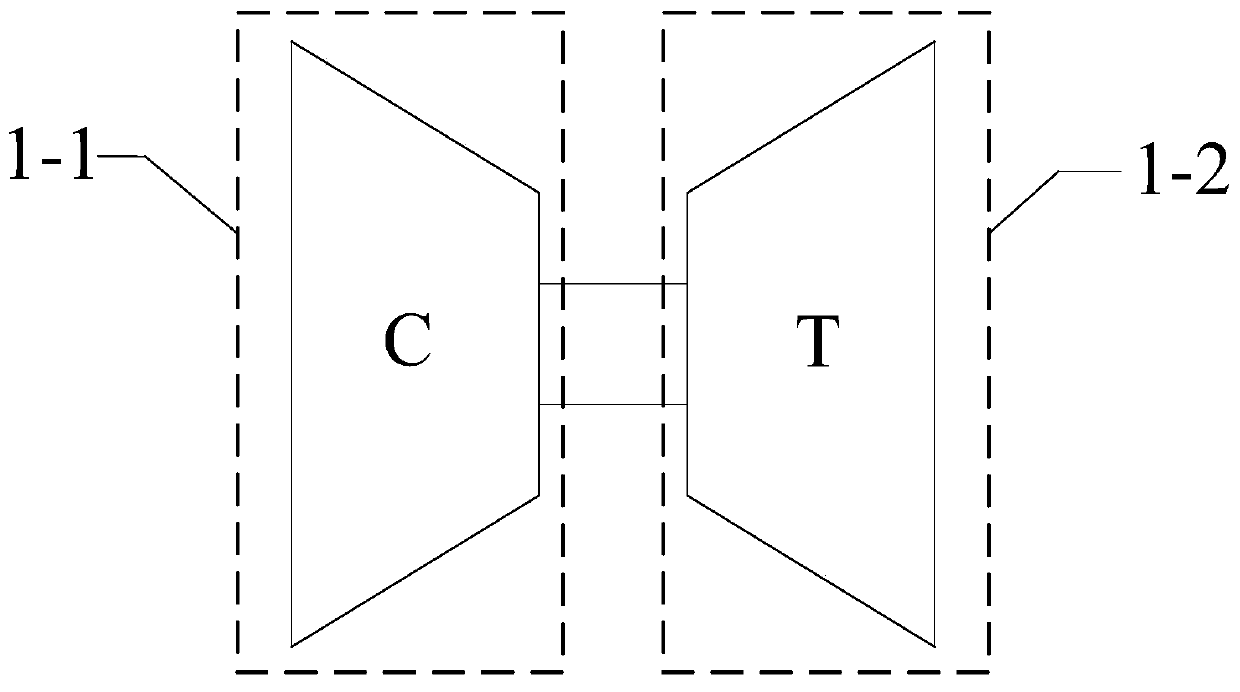

[0031] In this embodiment, the exhaust pipe blockage fault data is generated by simulation, and a marine diesel engine model is constructed by taking the 6S35ME-B9 diesel engine of MAN Company as an example.

[0032] Step S1, setting the structural parameters in the mathematical model of the diesel engine according to the parameters of the actual marine diesel engine, and establishing a practical and feasible model of the diesel engine.

[0033] Step S2, analyze the clogging fault of the exhaust pipe of the diesel engine, and determine to use the method of gradually reducing the diameter of the initial position of an exhaust manifold B9 to simulate the fault. When there is no fault factor, the diameter of the initial position of the exhaust manifold B9 is 170mm , set the initial position threshold diameter when a fault occurs to be 130mm. In order to accelerate the generation of failure data, the expected time for such failures is set to 50 days.

[0034] Step S3 is to select a...

Embodiment 2

[0038] This implementation case is used to simulate the insufficient cooling fault data of the air cooler 2, using the same marine diesel engine model as the experimental case 1.

[0039] Step S1, establishing the required diesel engine model according to the actual structural parameters of the diesel engine.

[0040] Step S2, analyze the insufficient cooling fault of the air cooler 2 of the diesel engine, determine the fault caused by the attachment of impurities to the simulated air cooler pipeline in this implementation case, and use the method of gradually reducing the cooling efficiency of the air cooler 2 for simulation. The cooling efficiency of the air cooler 2 is 89.5% when there is no fault, and the cooling efficiency threshold is 65%. Accelerate the generation of failure data, setting the expected time for such failures to be 51 days.

[0041] In step S3, the value of the increment constant λ in the growth Wiener process of the selected fault factor is -0.05%, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com