Shell making method and shell made by same

A manufacturing method and casing technology, applied to metal casings, electrical equipment casings/cabinets/drawers, electrical components, etc., can solve the problem of single casing color and visual effect, difficulty in improving product appearance competitiveness and added value, and casing metal texture Reduce other problems, achieve the effect of enhancing visual effect and attractive appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

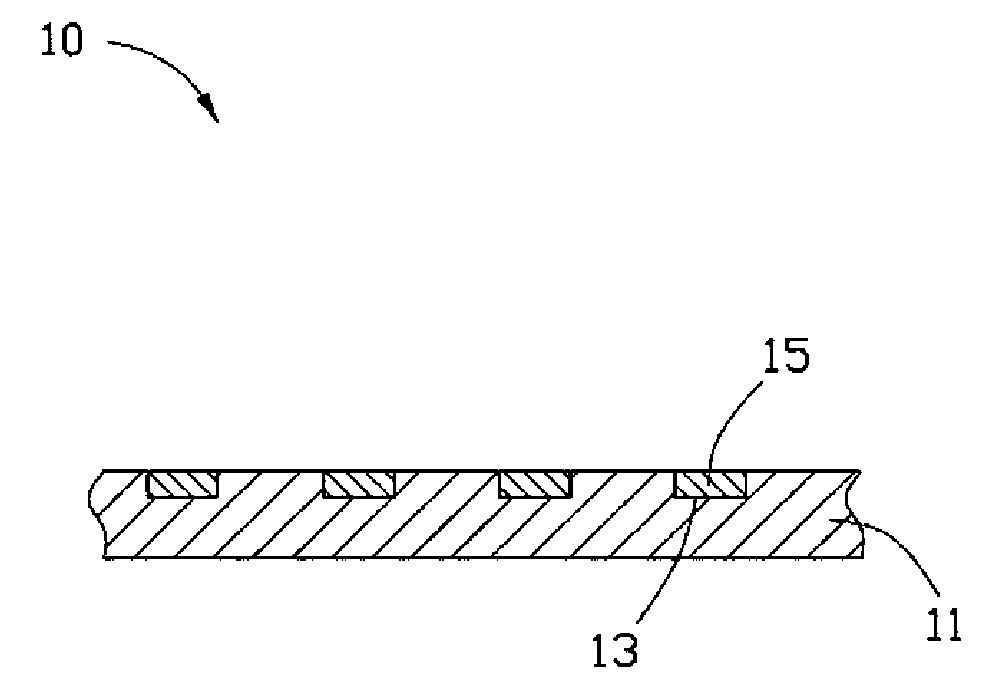

[0013] The manufacturing method of the shell of a preferred embodiment of the present invention comprises the following steps:

[0014] A metal base is provided. The metal base can be made of stainless steel.

[0015] A plurality of grooves are etched on a partial area of a surface of the metal base. The several grooves can be patterns with regular shapes or random patterns. The depth of the grooves can be between 0.1-0.12mm. The method for etching some grooves can be chemical etching, such as the metal substrate can be immersed in an etching solution containing copper ions, iron ions, chloride ions, sulfate ions and nitrate ions, and the metal ions in the etching solution A chemical reaction occurs with the area to be etched on the surface of the metal substrate to achieve the etching effect. The area on the surface of the substrate that does not need to be etched can be shielded by film masking.

[0016] Roughening treatment is performed on the plurality of grooves. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com