Shaftless conveyor with multi-connected assembly structure

A conveyor, shaftless technology, applied in the field of conveyors, can solve the problems of high processing and production costs, limited conveying volume, messy structure, etc., and achieve the effects of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

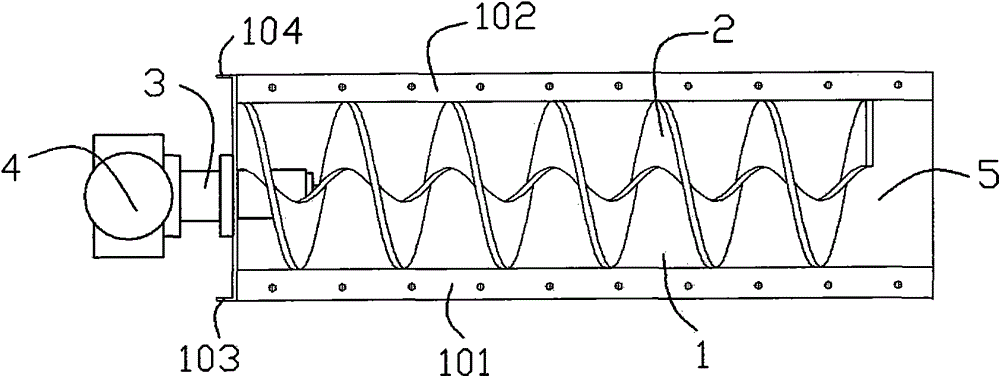

[0016] Examples, see attached Figure 1-3 A shaftless screw conveyor with a multi-assembling structure, including a housing 1, a channel 5 of the housing 1 is installed with a shaftless spiral blade 2, the shaftless spiral blade 2 through the reduction box 3 and the motor 4 Connection; the left side plate of the housing 1 is formed with a connecting groove 101, and the right side plate is formed with a connecting boss 102 that matches the connecting groove.

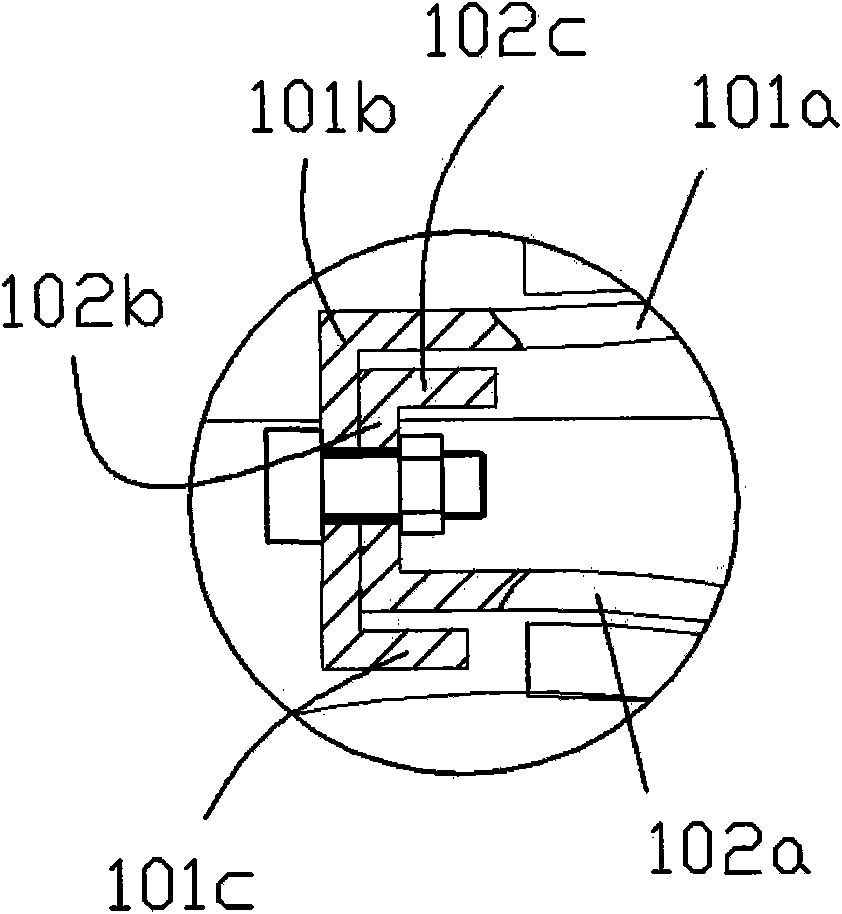

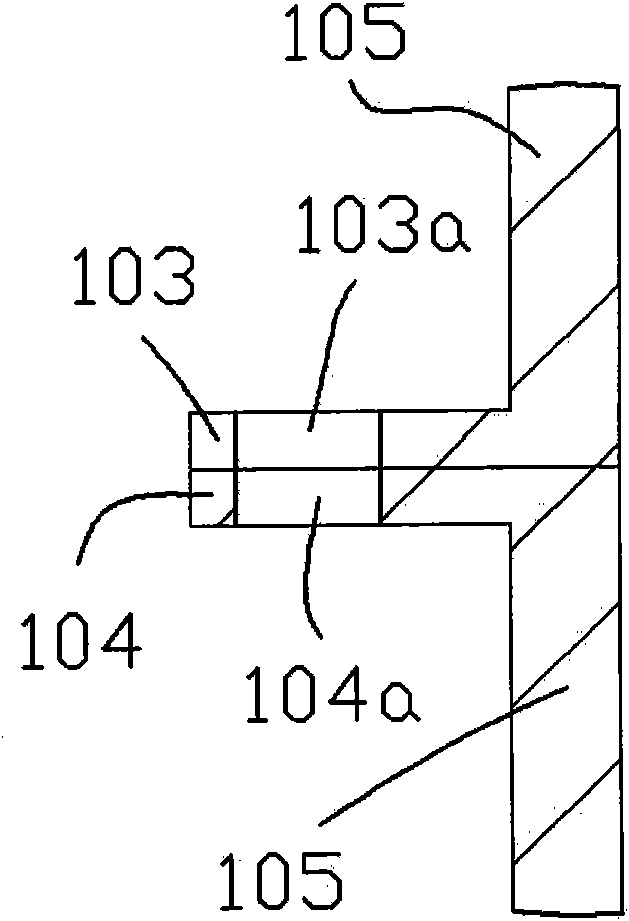

[0017] The connecting groove 101 is composed of the left side plate 101a of the housing, the groove horizontal plate 101b, and the groove vertical plate 101c. The groove horizontal plate is integrally formed on the left side plate of the housing and extends outward. The groove vertical plate is formed on the lower surface of the groove horizontal plate; the connecting boss 102 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com