Touch-type built-in full closed-loop control led dimming drive circuit

A technology of dimming drive and touch control, applied in the direction of electric light circuit layout, light source, electric light source, etc., can solve the problems of mass production inductance value deviation, input voltage fluctuation, general effect, etc., so as to reduce the risk of failure and make the circuit reliable. The effect of improving performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

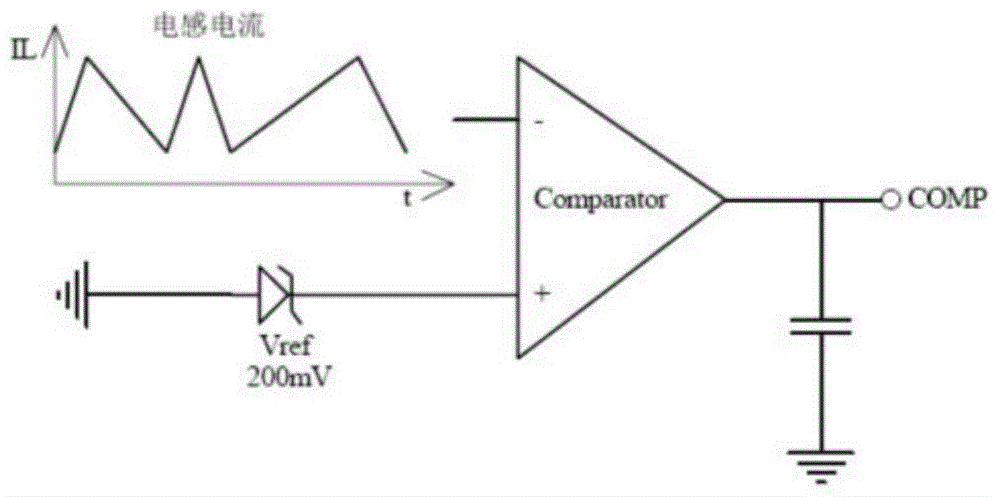

[0029] The external programmable PWM signal input provided by the chip DU8623 used in the present invention controls the output of the chip PWM signal via the MCU, and sets the output duty ratio of the PWM signal;

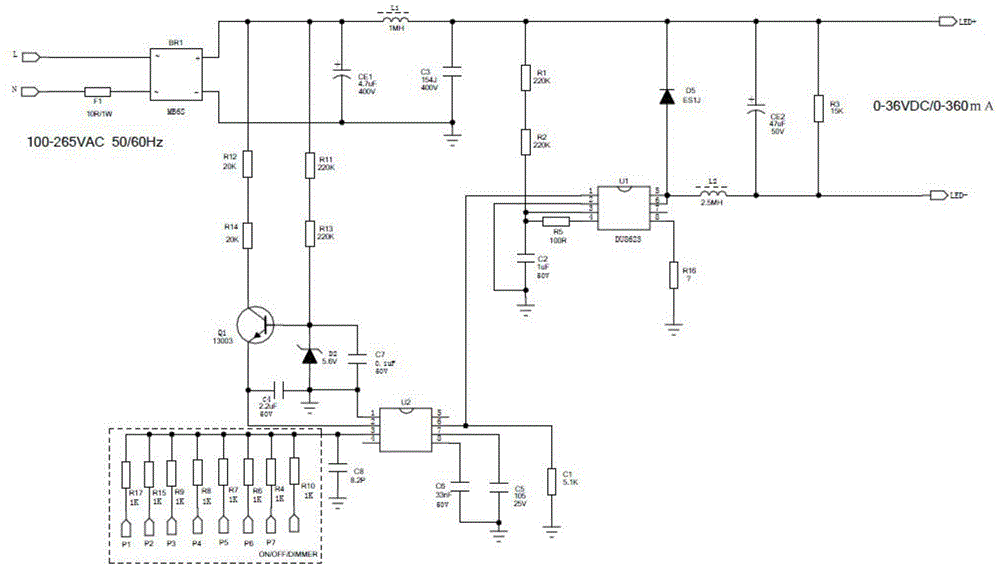

[0030] in figure 1 In, when the touch point is touched by hand (ON / OFF-DIMMER point or other contact points on the circuit, 1-8 touch points can be connected), the clutter signal induced by the human body enters the MUC chip through the resistance, which activates The data storage circuit inside the MCU chip, the data storage circuit will then compose the programmed LED light source output current duty cycle data, and send the data to the main control calculation circuit, and then use the above data to establish an internal database, through the database Convert the signal into the actual output duty cycle signal of the LED, and send the corresponding control signal to the DU8623 DIM dimming pin according to the set data, so that the LED can adjust its luminous flux o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com