Device for improving response stability of surface acoustic wave gas sensor

A gas sensor, surface acoustic wave technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve problems such as unstable response, and achieve the effect of reducing concentration balance time, response time and desorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

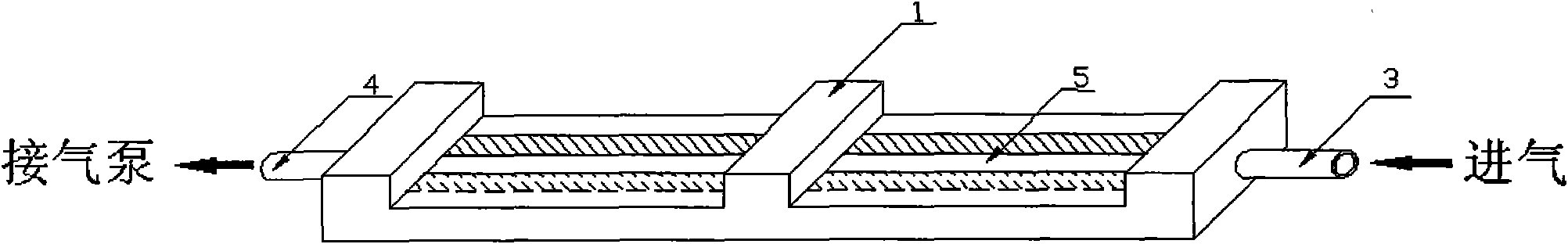

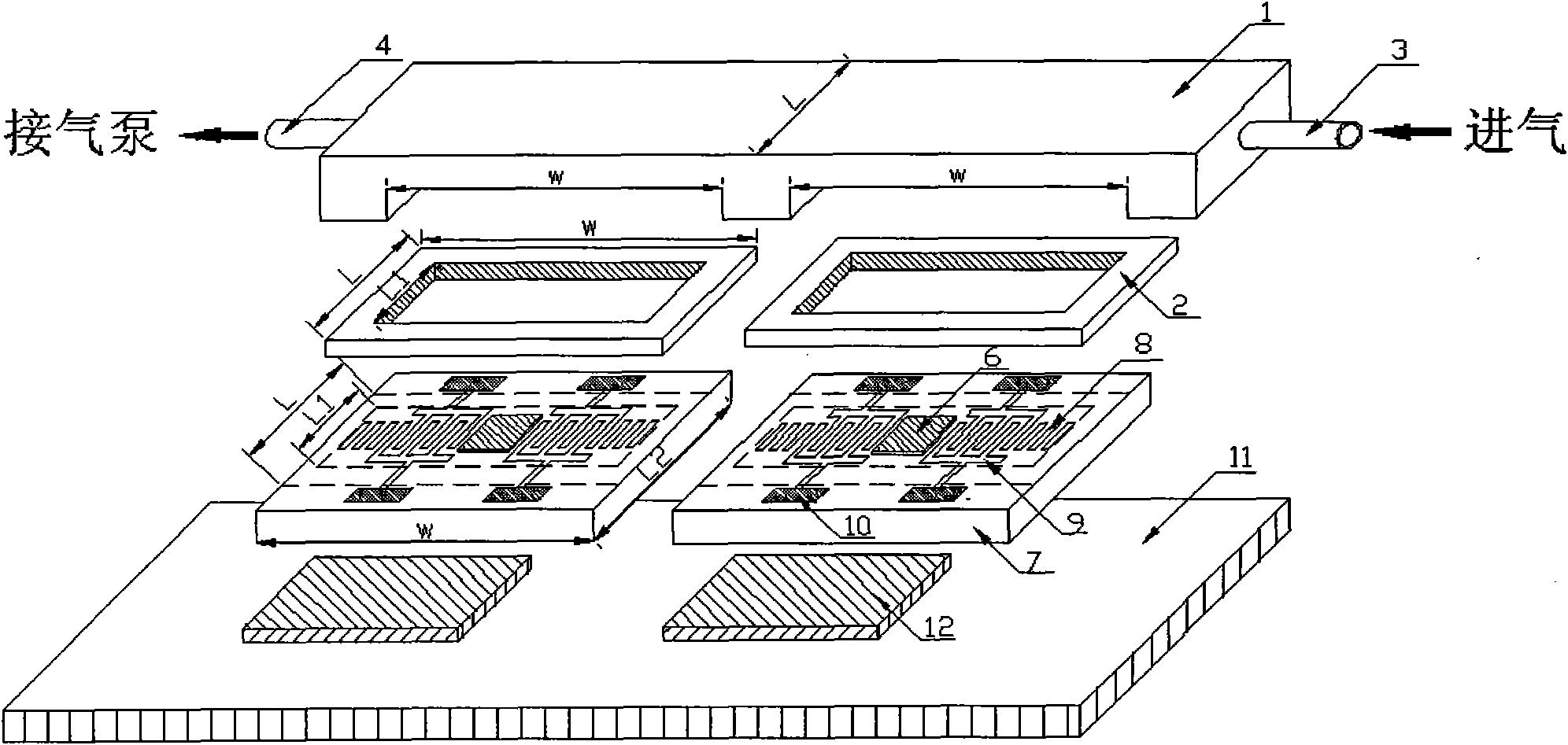

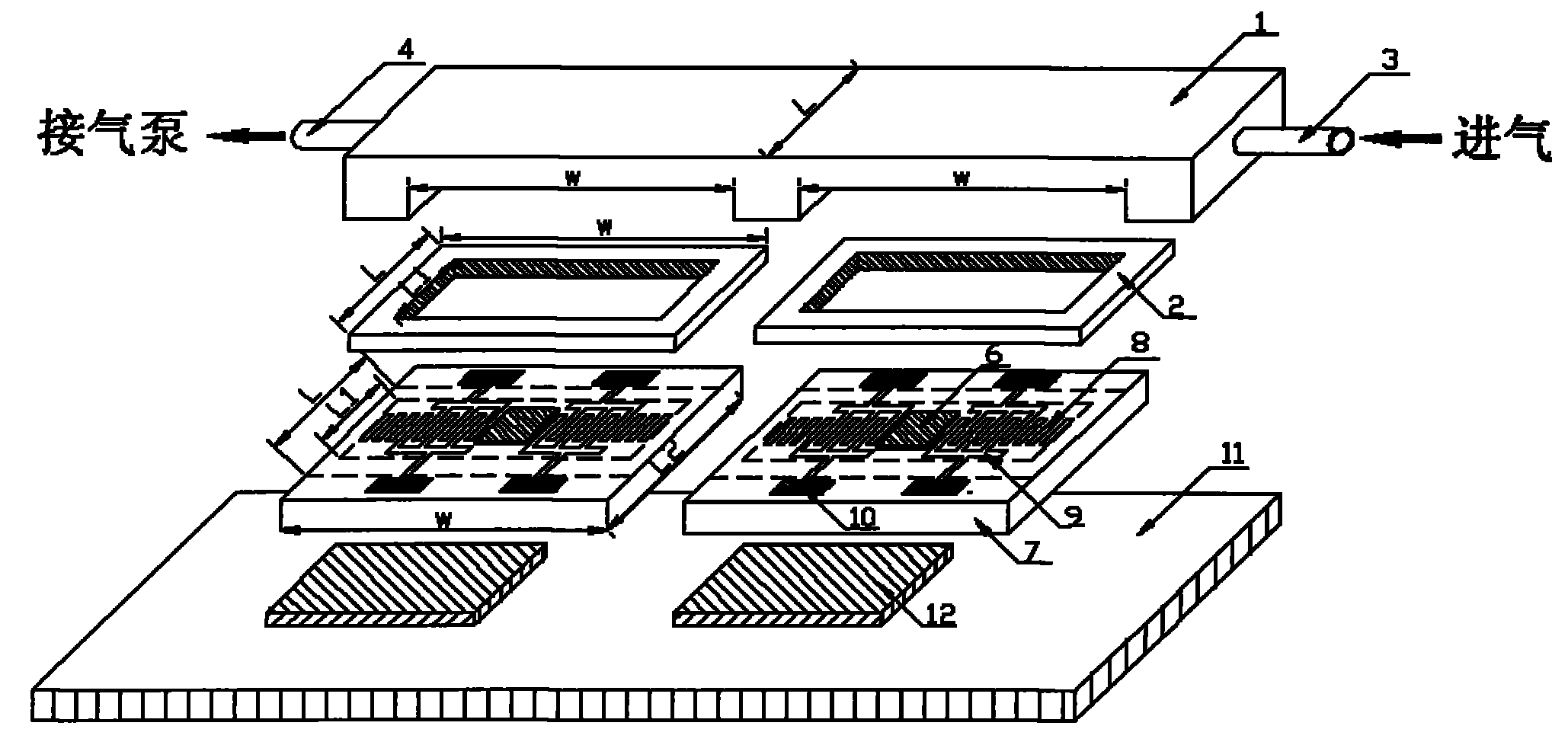

[0015] Attached below figure 1 and 2 And embodiment further describes the present invention:

[0016] The device for improving the response stability of the surface acoustic wave gas sensor includes a long strip-shaped hollow metal cover and an airtight gasket, and the metal cover is fastened on the substrate through the middle airtight gasket to form a closed metal gas The metal air chamber has an air inlet connected to the outside atmosphere and an exhaust port connected to the micro air pump; the width of the metal cover is narrower than the width of the substrate, and the width of the hollow part of the metal cover is larger than the width of the electrode, so that The electrode and the sensitive film are located in the hollow part of the metal air chamber, and the welding pad of the electrode is not covered by the metal cover and exposed outside for wire welding.

[0017] The following is a specific preparation method of the present invention:

[0018] Firstly, the SAW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com