Method and system for transferring adjustment patterns during production

A production process and adjustment mode technology, applied in general control systems, control/regulation systems, manufacturing computing systems, etc., can solve problems such as reducing system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

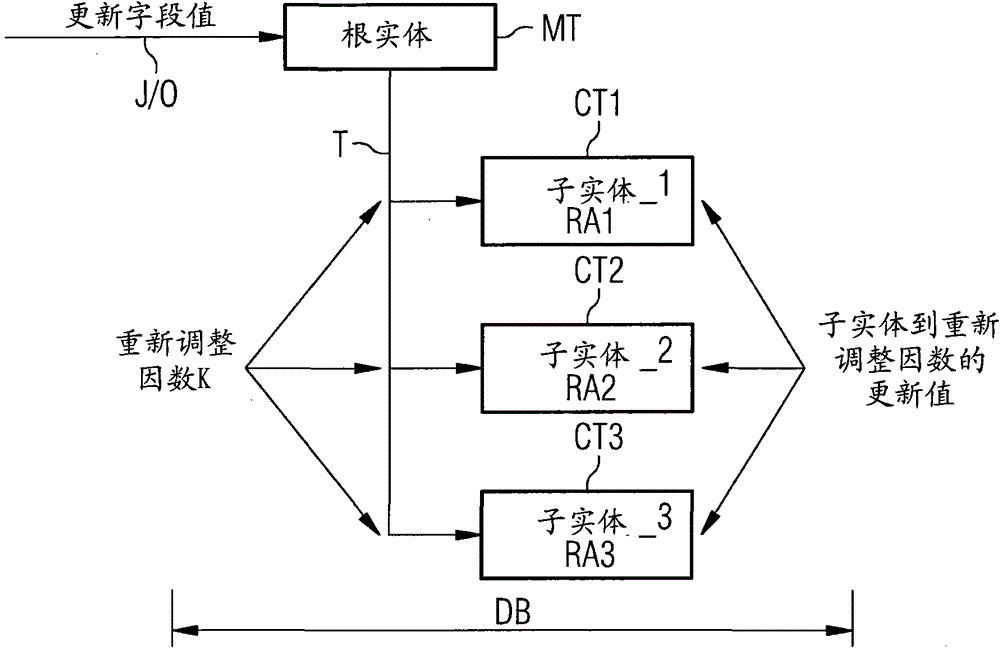

[0034] Such as Figure 5 Schematically represented, the Manufacturing Execution System MES is an intermediate level between the upper level of the ERP and the lower level of the factory floor providing computing machines and software tools 1 to n including software for production order management Tool 1, which receives production requests from ERP, and a software tool 2 for production modeling, which supports the phases of selecting and managing the resources to be involved in the manufacturing process, namely employees, machines and materials in order to realize the planned manufacturing process within the required time constraints.

[0035] MES is based on ISA (International Standards Association) standard S95, which defines how software tools 1 to n can implement production at the plant floor level and communicate with the plant floor level. More particularly, S95 is basically based on a manufacturing process represented by a plurality of continuous process segments, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com