Impact absorption member

A technology for absorbing parts and impact force, applied in the direction of elastic shock absorbers, bumpers, etc., can solve the problems of impact energy deviation, inability to guarantee deformation mode, uncertain relationship, etc., and achieve the effect of preventing deviation of absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

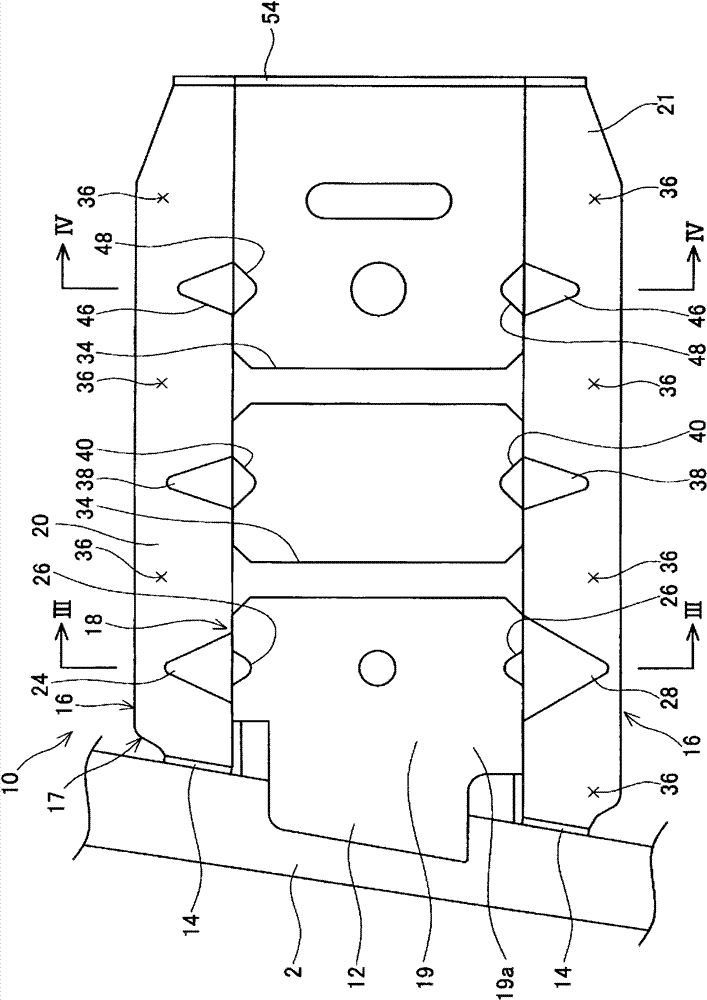

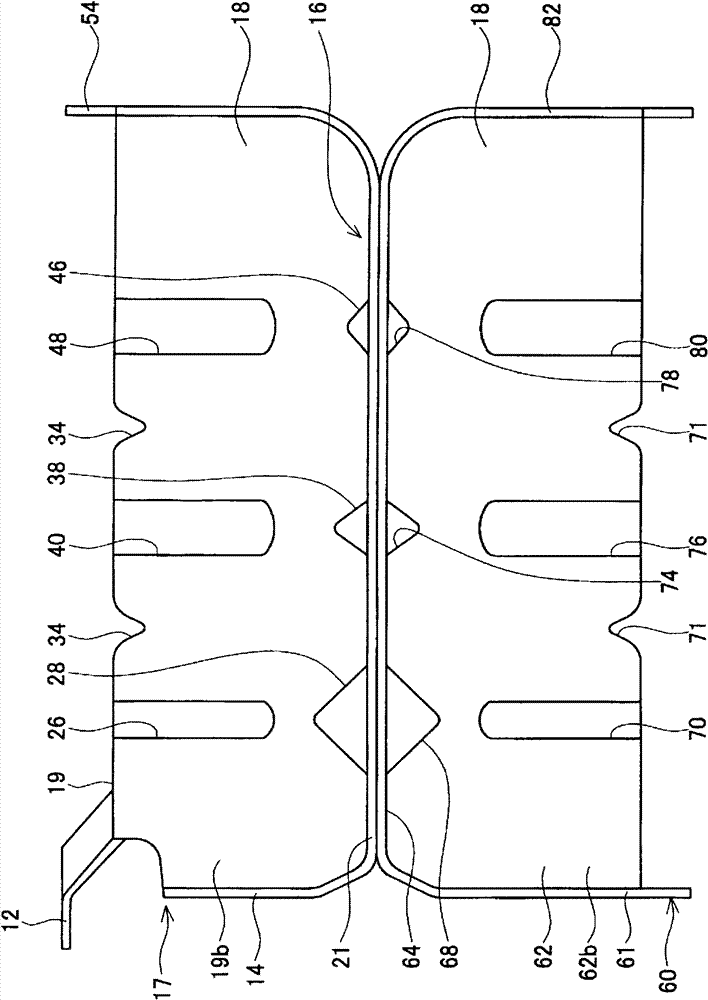

[0024] The technical features of the present invention described above are listed below.

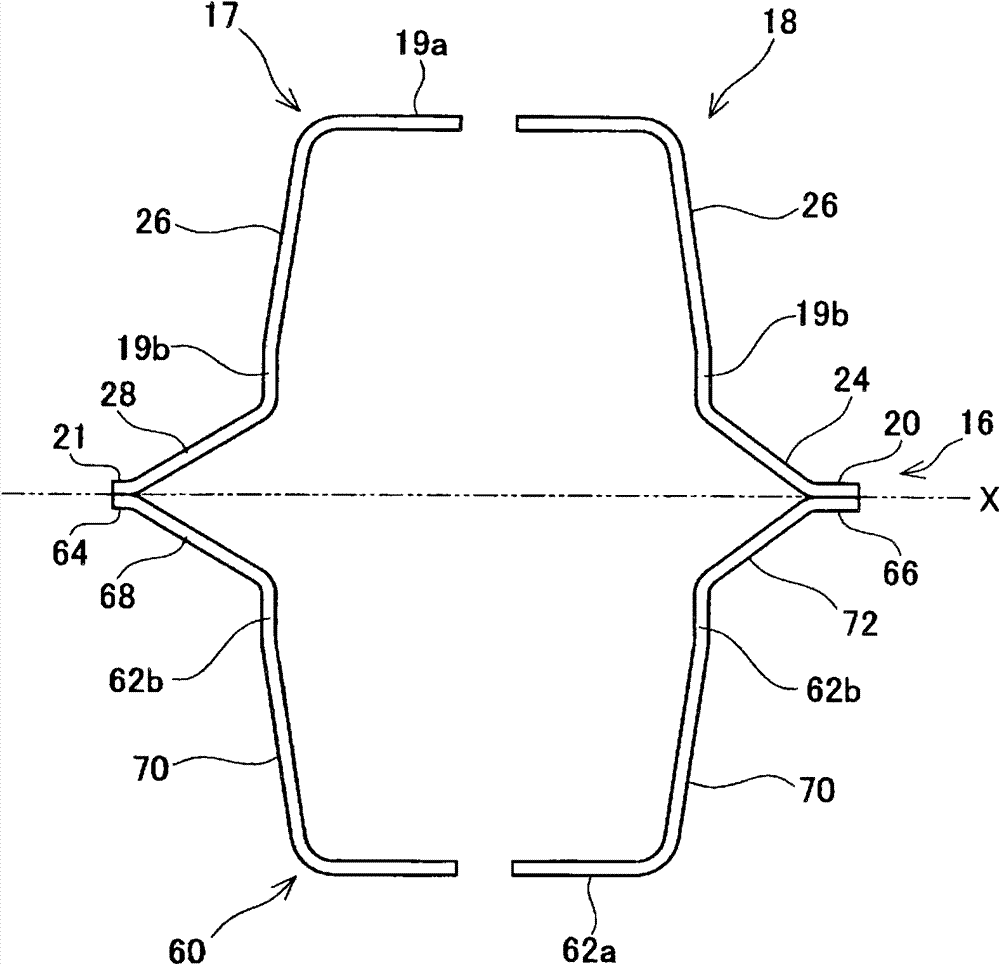

[0025] (Technical Feature 1) The impact absorbing member may have a third body in addition to the first body and the second body. At this time, the third body has a third partial cylinder wall and a pair of third extensions. Wherein, the third part of the cylinder wall constitutes a part of the cylinder wall, that is, a part that cuts out the cylinder wall in the circumferential direction of the cylinder, and a pair of third extensions are formed on the third part of the cylinder wall in the circumferential direction. ends.

[0026] At this time, the second extension part is joined to the first extension part, the third extension part is joined to the second extension part, and the first extension part is joined to the third extension part. The tube is surrounded by the first part of the tube wall, the second part of the tube wall and the third part of the tube wall.

[0027] (Technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com