Systems and methods for producing oil and/or gas

A technology for oil recovery and separation agent, applied in the field of oil and/or gas production systems, can solve the problems of high purchase and transportation costs, high purity, high carbon disulfide production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

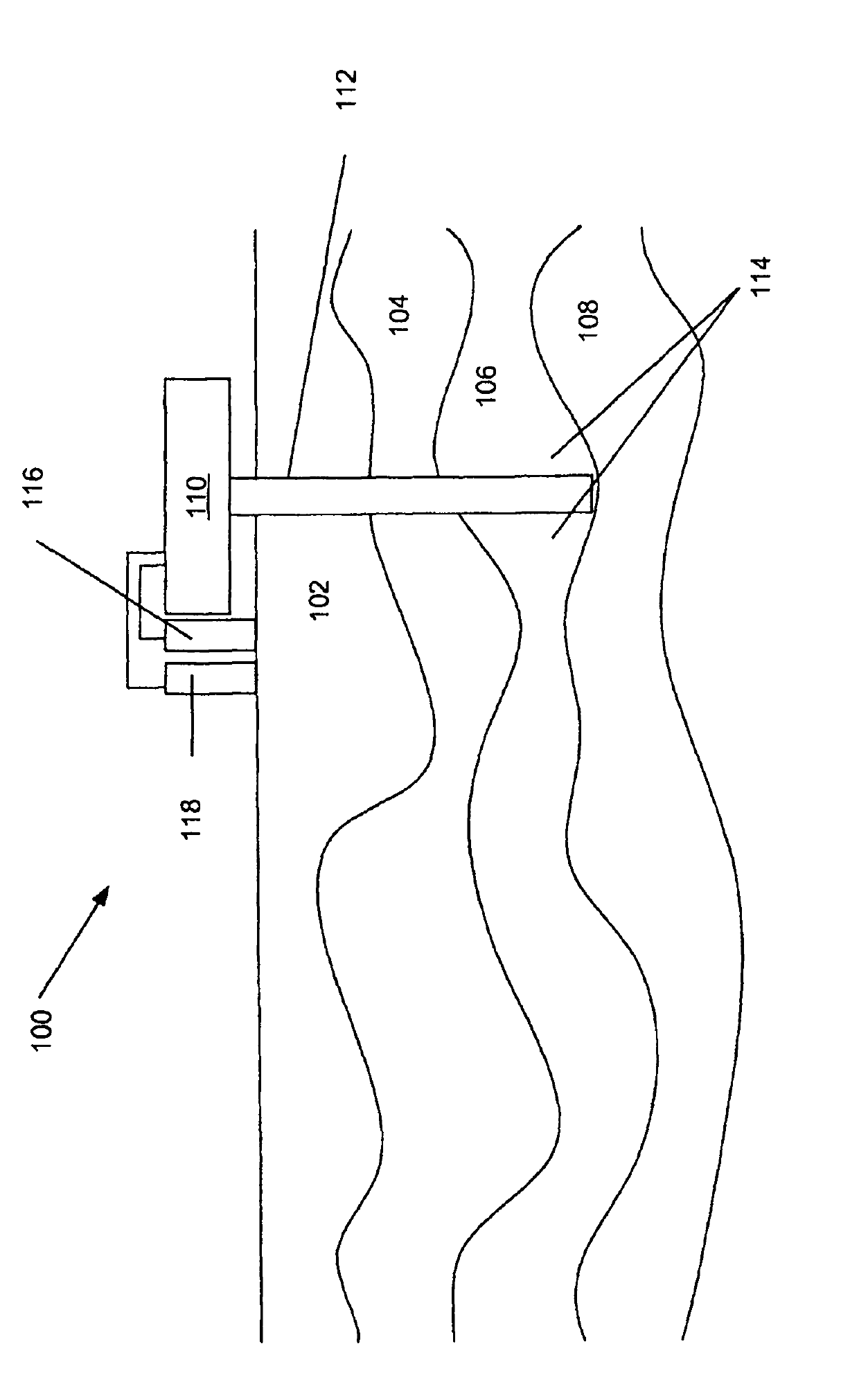

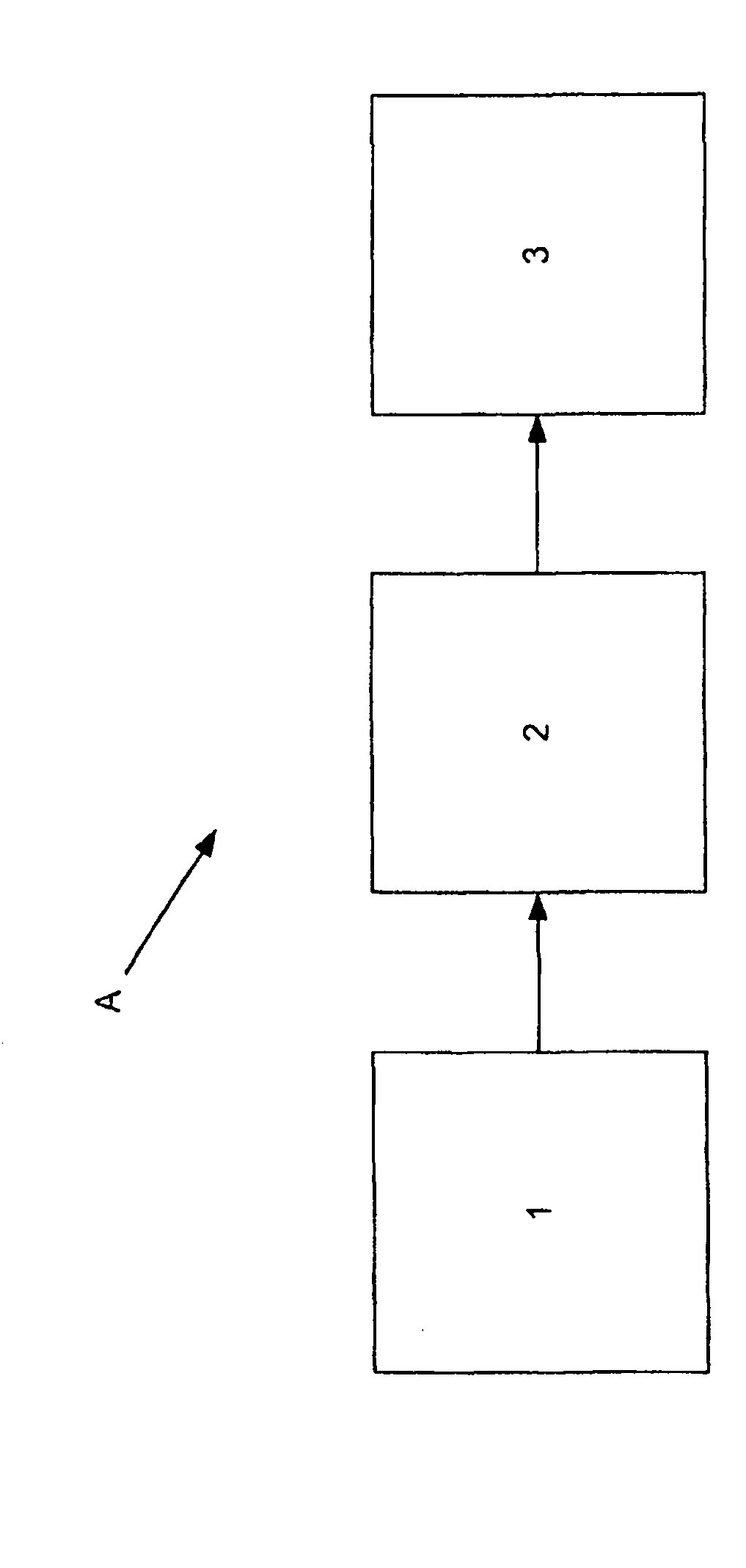

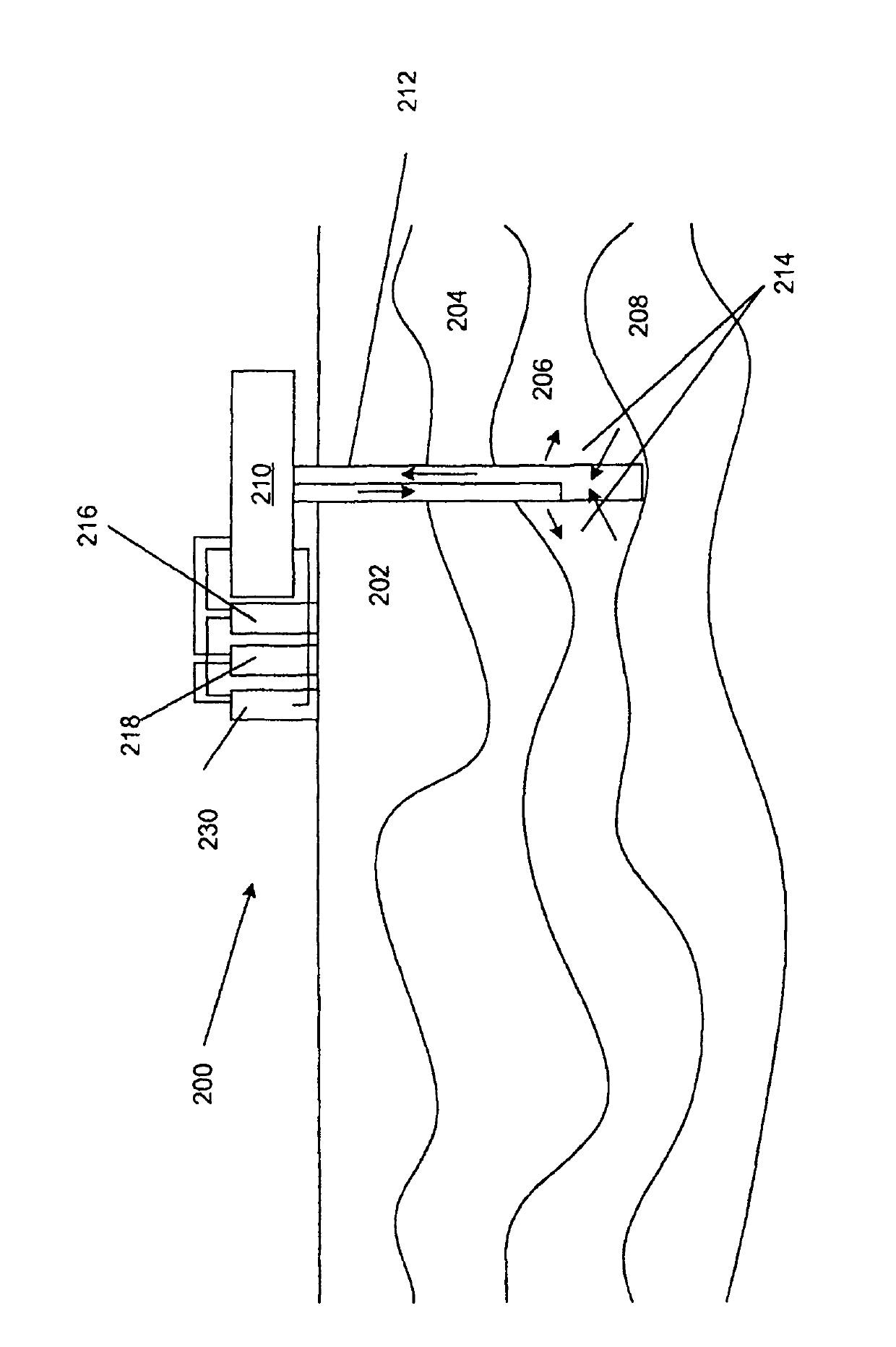

[0029] figure 2 :

[0030] In one embodiment of the invention, reference is now made to figure 2 , describes a method A for the production of oil and / or gas comprising the disposal of sulfur compounds. Method A includes step 1 in which sulfur and / or sulfur-containing compounds are obtained and optionally released into the formation. In step 2, at least a portion of the sulfur compounds are converted to a carbon disulfide formulation and / or a carbon oxysulfide formulation, optionally within the formation. In step 3, at the conclusion of the EOR operation, the oil and / or gas may be separated from the carbon disulfide formulation and / or carbon oxysulfide formulation, and the oil recovered from the subterranean formation, and the carbon disulfide formulation and / or carbon disulfide formulation may be separated within the formation. The carbon oxysulfide formulation is transformed into another compound.

[0031] step 1:

[0032] Obtaining the sulfur-containing compound ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com