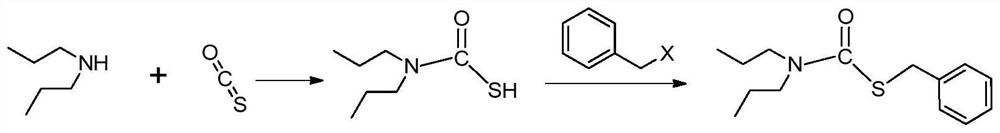

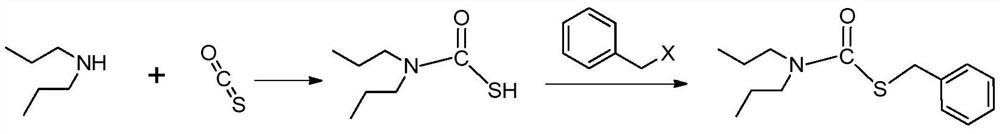

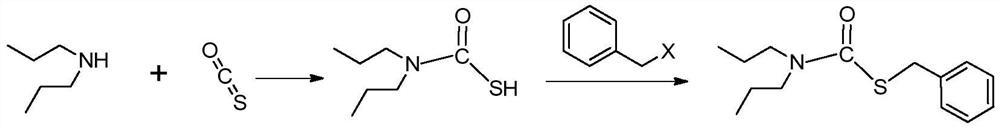

Preparation method of prothiocarb

A technology of procarbocarb and benzyl halide, which is applied in the field of pesticide preparation, can solve the problems of high content of impurity dibenzyl disulfide, cumbersome operation process of procarbocarb, large amount of wastewater, etc., and achieve easy and stable process operation The effect of control, short preparation reaction time and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the present embodiment, by the following method to prepare procyridone, specifically comprises the following steps:

[0043] Set up a four-necked flask reaction device equipped with a gas guide, a bubbler, a stirring paddle and a thermometer and a tail gas absorption device for sodium hydroxide solution, weigh 99.76g (0.976mol) (content 99%) of di-n-propylamine, and cool it to 10 ℃, introduced 26.97g (0.440mol) (content 98%) carbon oxysulfide, the ventilation time was 1h, the whole process temperature was 10-20℃, after the ventilation was over, the system was heated to 25℃, and 54.98g (0.430mol) was added dropwise. (content 99%) benzyl chloride, dripping time 1h, whole process temperature 25-30 ℃, after the end of dripping, sample analysis after 25-30 ℃ incubating for 3h, HPLC analysis of benzyl chloride content is 0.5119%, benzyl chloride The content was 93.0803%, and the reaction was completed.

[0044] After adding 41.6g of water to the system, the temperature wa...

Embodiment 2

[0046] In the present embodiment, by the following method to prepare procyridone, specifically comprises the following steps:

[0047] Set up a four-necked flask reaction device equipped with a gas guide, a bubbler, a stirring paddle and a thermometer and a tail gas absorption device for sodium hydroxide solution, weigh 101.09g (0.989mol) (content 99%) of di-n-propylamine, and cool it to 13 ℃, feed 27.71g (0.452mol) (content 98%) carbon oxysulfide, the ventilation time is 50min, the whole process temperature is 10-20 ℃, after the ventilation is over, the system is heated up to 25 ℃, and 54.98g (0.430mol) is added dropwise (content 99%) benzyl chloride, dripping time 1h, whole process temperature 25-30 ℃, after the end of dripping, incubate at 25-30 ℃ for 3h, sample and analyze, the content of benzyl chloride by HPLC analysis is 0.4263%, and the benzyl chloride is 0.4263%. The content was 93.8094%, and the reaction was completed.

[0048] After adding 41.6g of water to the sys...

Embodiment 3

[0050] Set up a four-necked flask reaction device equipped with a gas guide, a bubbler, a stirring paddle and a thermometer, and a tail gas absorption device for sodium hydroxide solution, weigh 103.23g (1.01mol) (content 99%) of di-n-propylamine, and cool it to 13 ℃, introduced 28.81g (0.47mol) (content 98%) carbon oxysulfide, the ventilation time was 1h, the whole process temperature was 10-20℃, after the ventilation was over, the system was heated to 25℃, and 54.98g (0.430mol) was added dropwise. (content 99%) benzyl chloride, dripping time 1h, whole process temperature 25-30 ℃, after the end of dripping, sample analysis after 25-30 ℃ incubating for 3h, HPLC analysis of benzyl chloride content is 0.4039%, benzalkonium chloride The content was 93.8831%, and the reaction was completed.

[0051] After adding 41.6g of water to the system, the temperature was raised to 45°C, acidified to pH=1.55 with 32% hydrochloric acid solution, the whole process temperature was 45-50°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com