A kind of crystalline n-substituted polythiocarbamate and its preparation method

A polythiourethane, crystalline technology, applied in the field of crystalline N-substituted polythiourethane and its preparation, to achieve the effect of simple synthesis, good thermal performance and high melting point

Active Publication Date: 2021-08-17

CHANGSHU INSTITUTE OF TECHNOLOGY

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So far, there has been no report on the preparation of crystalline polythiourethane by carbon oxysulfide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-11

[0060] The parameters are shown in Table 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

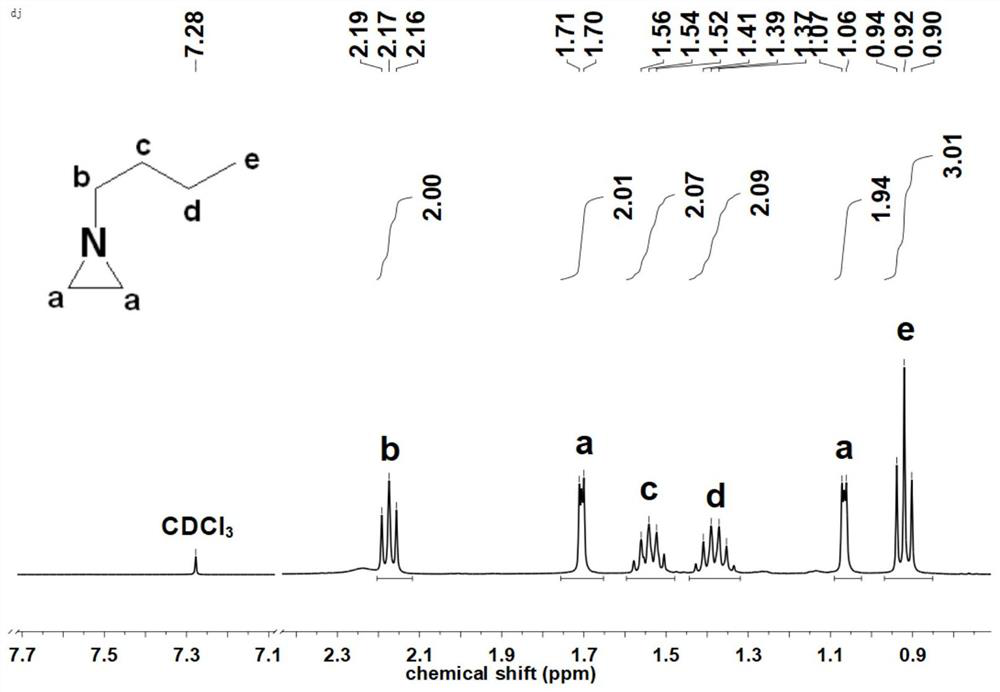

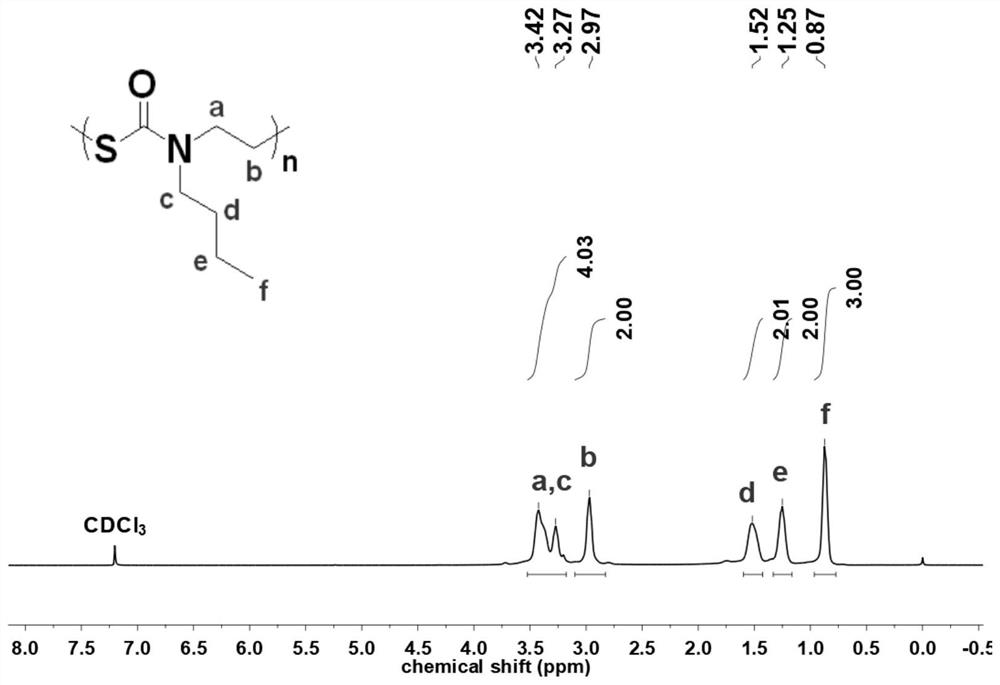

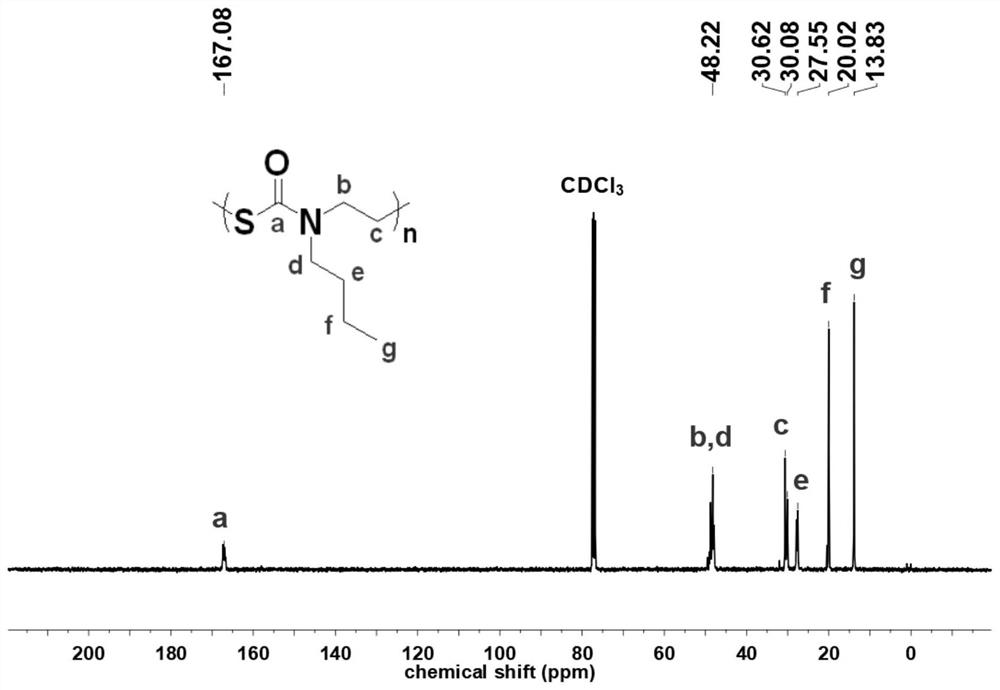

The invention belongs to the technical field of polymer materials, and in particular relates to a crystalline N-substituted polythiourethane and a preparation method thereof. The present invention uses carbon oxysulfide and N-substituted aziridine as raw materials to obtain crystallized N-substituted polythiourethane by copolymerization under bulk or solvent conditions. The method developed by the present invention has the following advantages: it can react itself without a catalyst; the raw materials are cheap and easy to obtain, and the synthesis is simple, without using toxic mercapto compounds and isocyanate compounds in the traditional system; the prepared N-substituted polythiocarbamic acid The main chain structure of the ester polymer is clear and has a fully alternating structure; the polymer is crystalline and has excellent thermal stability. The polymer is easy to recycle and reuse, and can be thermally degraded into a five-membered ring N-substituted thiocarbamate with application value, without any additional impurities or volatile pollutants, and is an environmentally friendly Recyclable specialty polymers.

Description

technical field [0001] The invention belongs to the field of polymer material synthesis, and in particular relates to a crystalline N-substituted polythiourethane and a preparation method thereof. Background technique [0002] Polythiourethanes are widely used in optical materials, coatings, and medical materials due to their enhanced properties such as refractive index, adhesive strength, biocompatibility, and mechanical properties. In existing synthetic methods, such as patents (CN1171924C; CN1405198A; CN105229046A), polythiourethanes can be synthesized by a base-catalyzed nucleophilic addition reaction of dithiols to diisocyanates. Obviously, raw material dithiol and diisocyanate are highly toxic, and their chemical properties are unstable in addition, and storage and use cost are higher, and these factors are all unfavorable for synthesizing polythiourethane. In addition, the polyaddition reaction of bifunctional five-membered cyclic dithiocarbonate and diamine can also...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G71/04

CPCC08G71/04

Inventor 罗铭古玉川吴双左晓兵胡昕

Owner CHANGSHU INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com