Structure and method for connecting underframe equipment bay and vehicle body

A technology for connecting structures and equipment cabins, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., which can solve the problem of high technical difficulty and component cost in the installation and positioning of equipment under the car, which affects the light weight of the car body chassis Quantitative design, unfavorable rail vehicle running speed and other issues, to achieve the effect of reducing design difficulty, reducing the weight of the car body, and improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

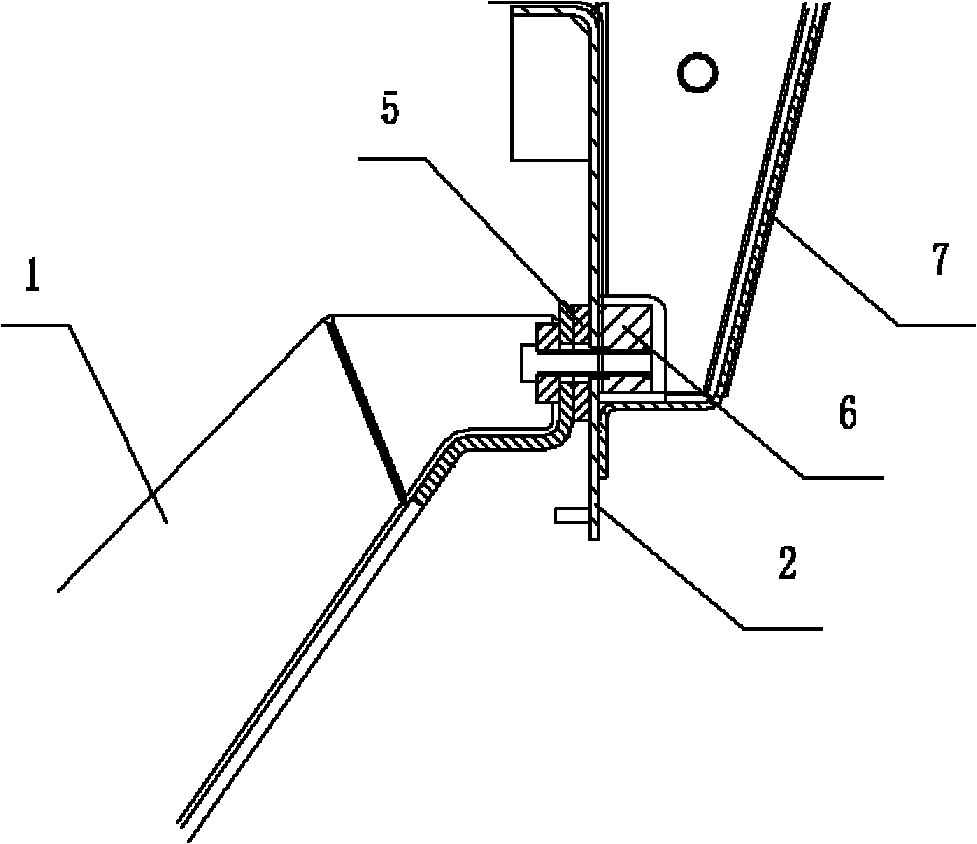

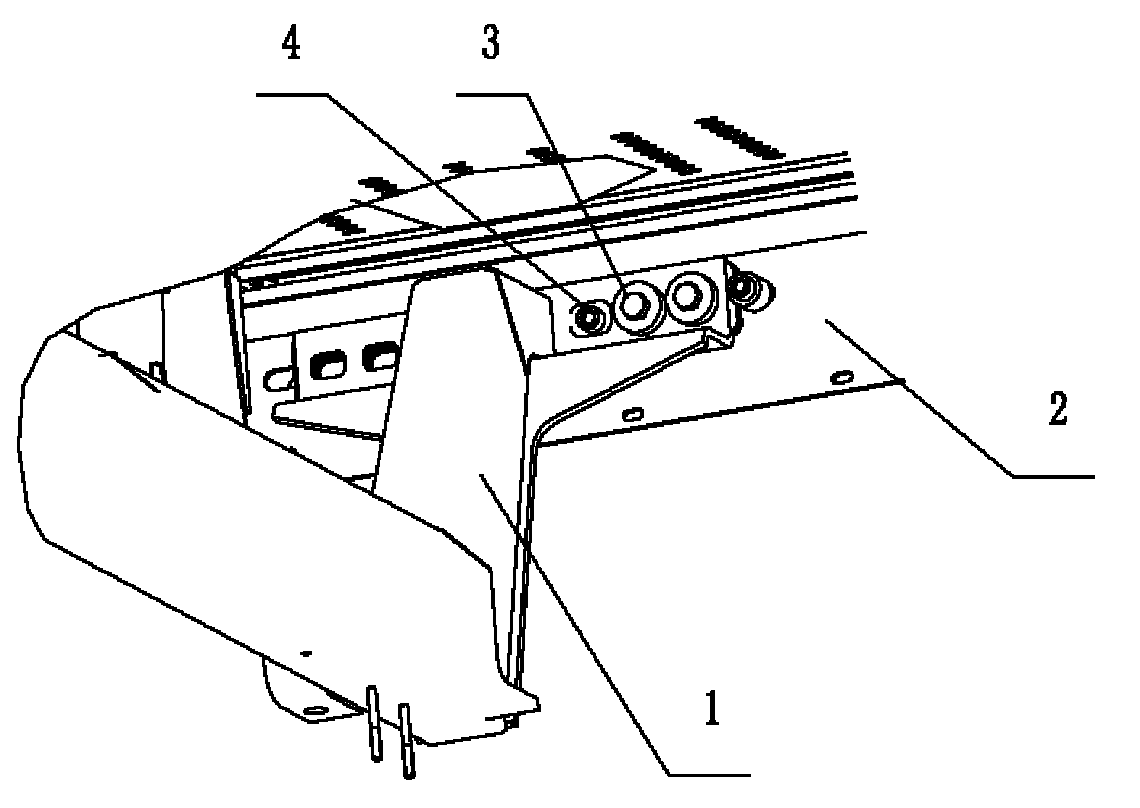

[0030] Example 1, such as figure 1 with figure 2 As shown, a coupling structure applied to high-speed rail vehicles, the coupling structure plays a role in coupling the equipment compartment of the underframe and the car body. specifically,

[0031] The connection structure mainly includes an installation beam 1 connecting the equipment compartment of the underframe.

[0032] The mounting beam 1 is fastened to the side beam 2 of the vehicle body underframe by a connecting bolt 3, and the connecting bolt 3 is applied with a tightening torque of 150-200 Nm on the side beam 2 of the vehicle body underframe.

[0033] A pad 5 with a thickness of 10 mm is lined between the installation beam 1 and the side beam 2 of the vehicle body underframe.

[0034] A safety bolt 4 is also fastened between the mounting beam 1 and the side beam 2 of the car body underframe. The safety bolt 4 is connected to the fixing plate 6 on the inner side of the side beam 2 of the car body underframe. The fixing pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com