Dynamic ice storage ice-melting system capable of watering at constant low temperature

An ice storage and ice melting technology, applied in air conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as user discomfort and terminal temperature drop, and ensure normal operation and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

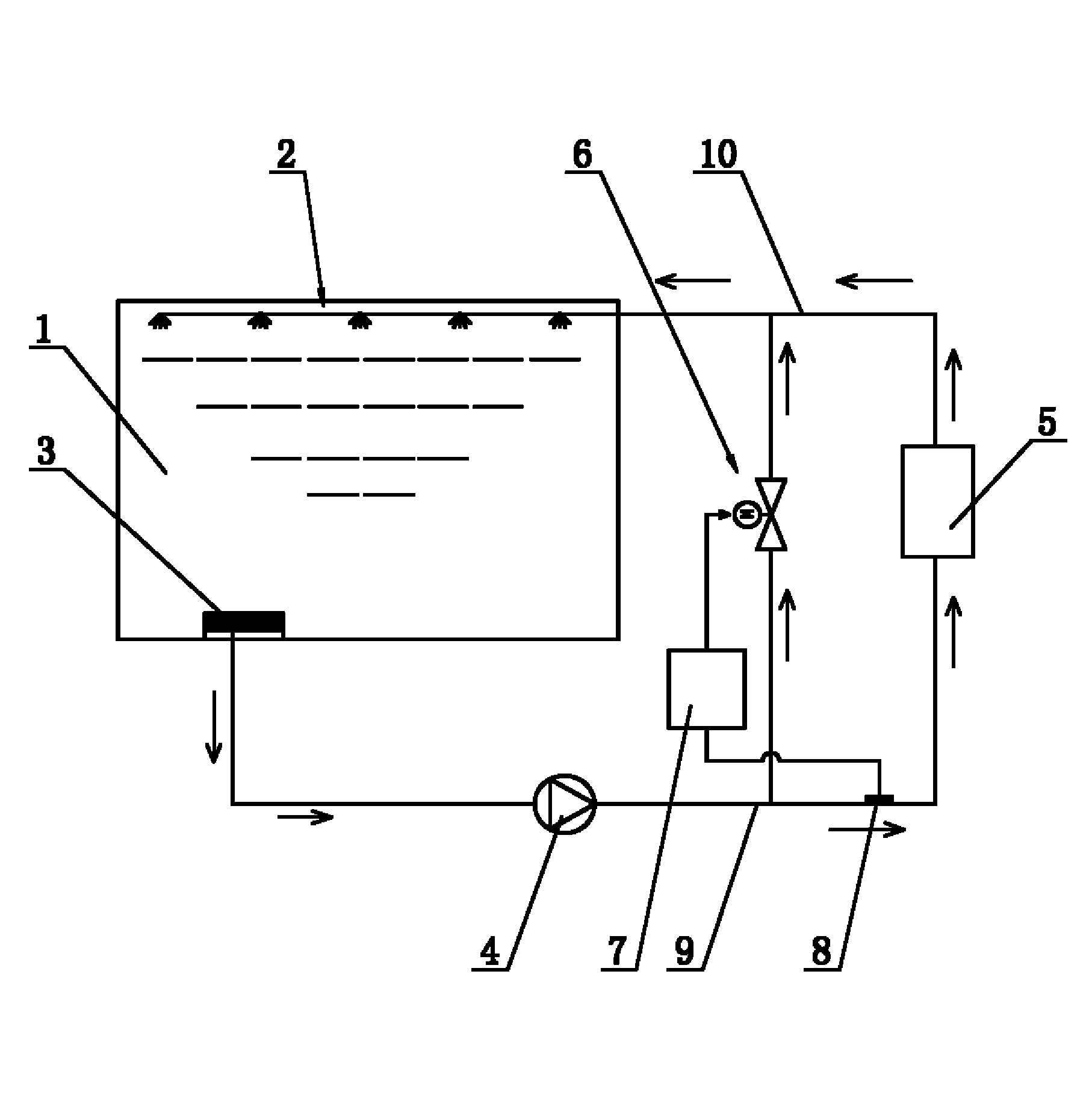

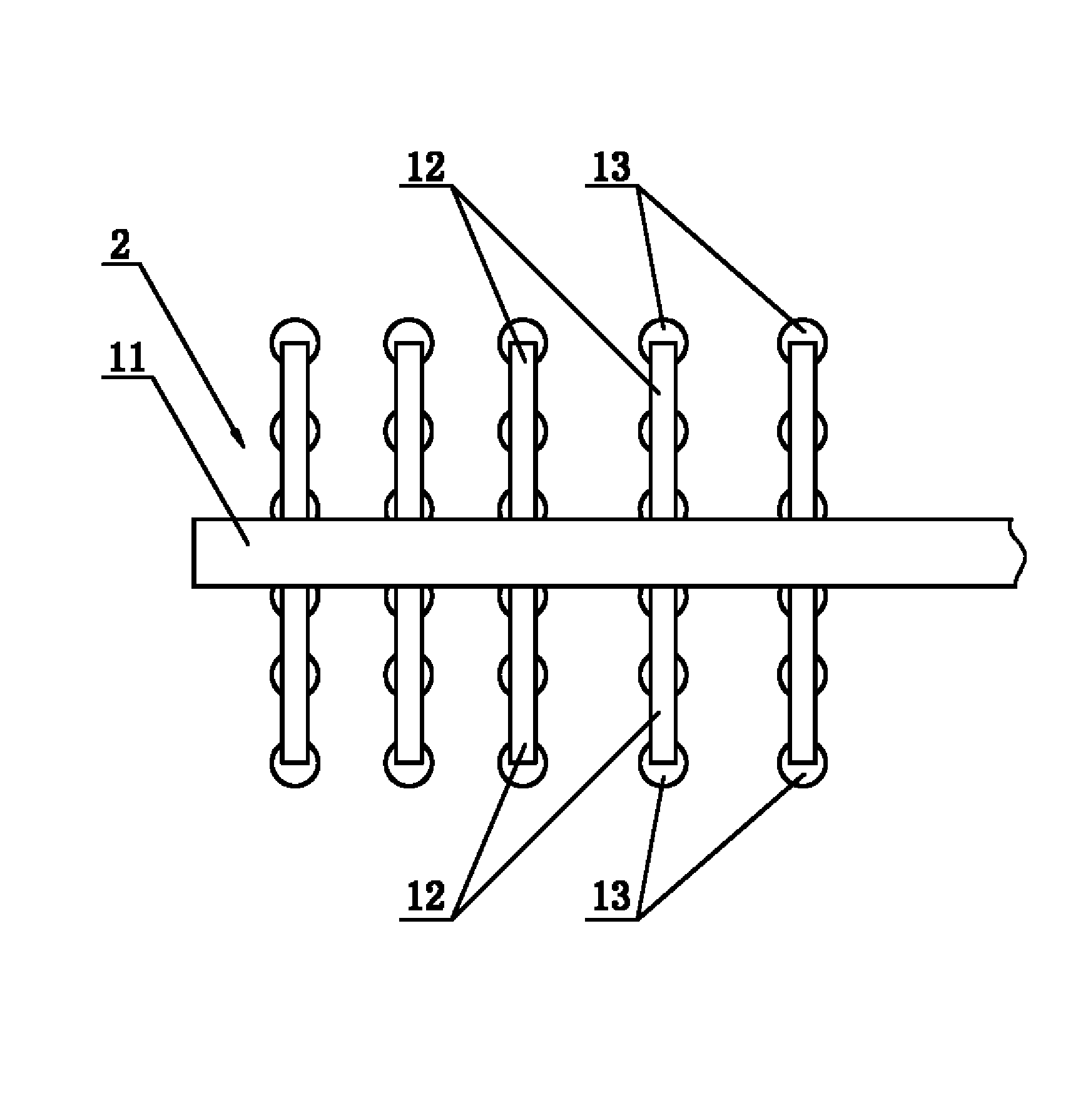

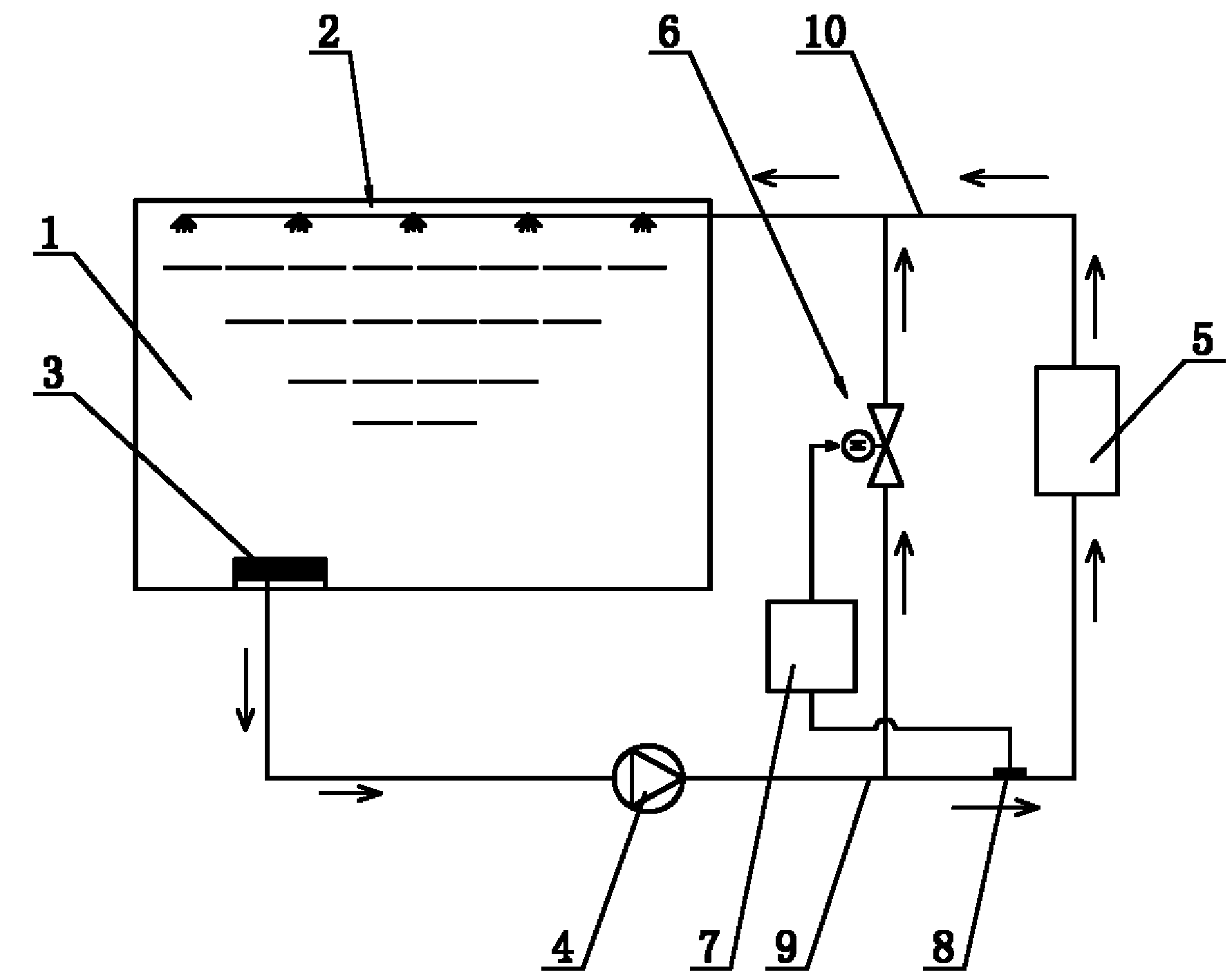

[0015] as attached figure 1 with figure 2 As shown, a dynamic ice storage cold-melting system with constant low-temperature water outlet includes an ice storage tank 1, a spray device 2 arranged in the upper part of the ice storage tank 1, a filter device 3, an ice-melting water pump 4 and an end coil 5, There is an opening at the bottom of the ice storage tank 1, and the filter device 3 is installed in the opening. The opening of the ice storage tank 1 communicates with the inlet of the ice-melting water pump 4, and the outlet of the ice-melting water pump 4 communicates with the inlet of the end coil 5. The outlet of the coil pipe 5 communicates with the inlet of the spray device 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com