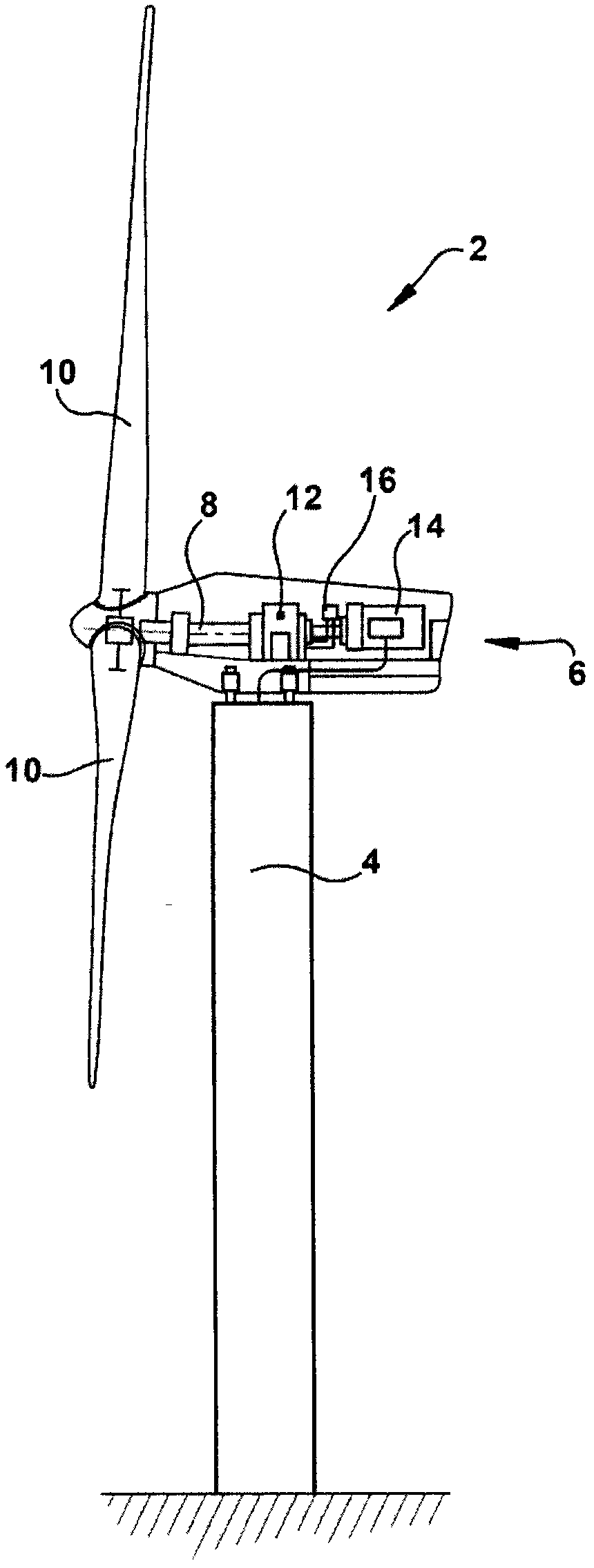

Methods of manufacture of wind turbine blades and other structures

A technology of ribs and fibers, applied in the field of improved structural configuration, which can solve the problems of increased failure chance, tower deformation, inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

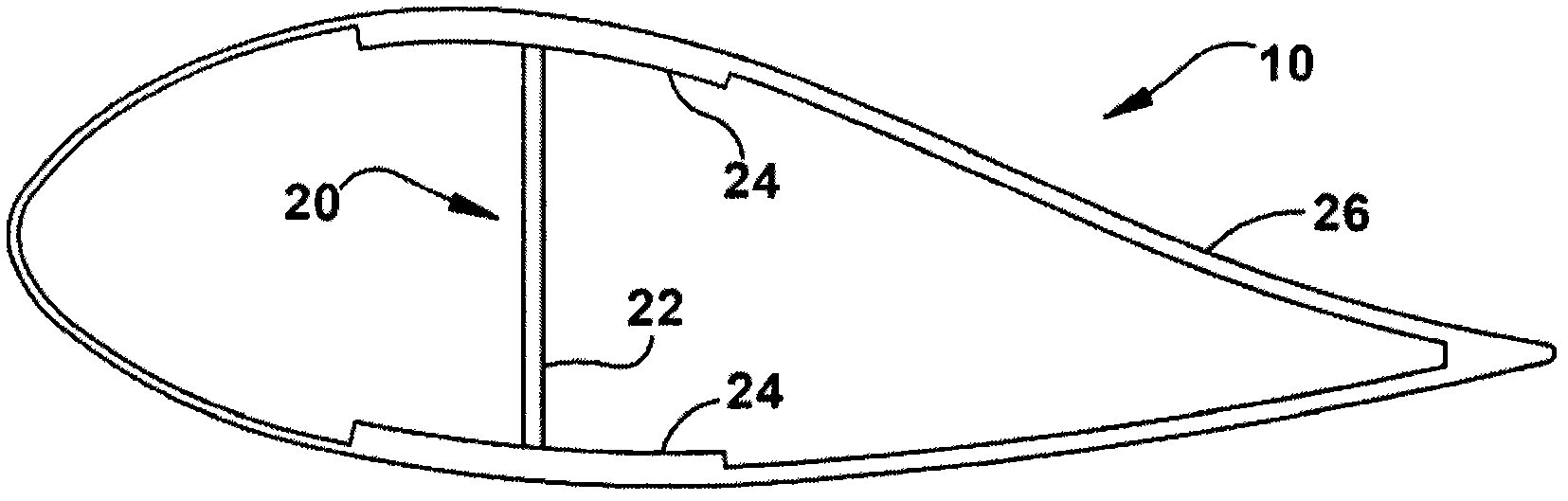

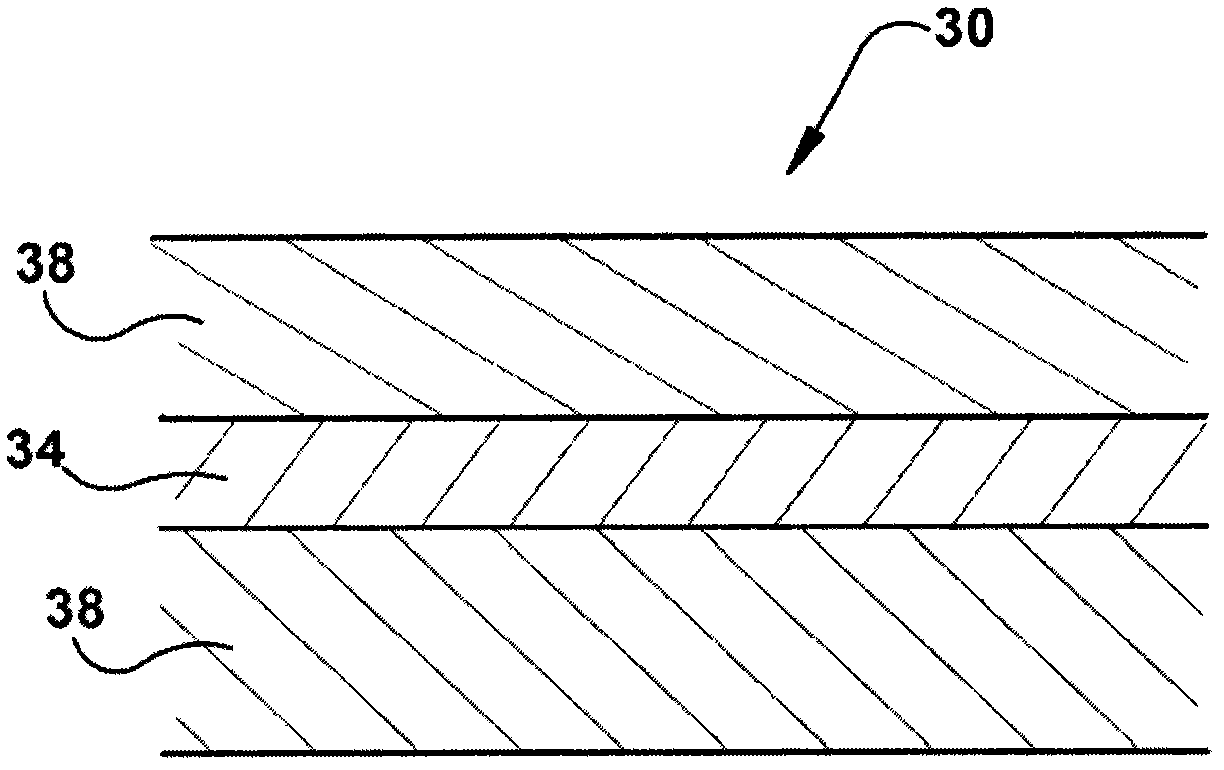

Embodiment Construction

[0063] Generally, as those of ordinary skill in the art will appreciate, the blade of a wind turbine is constructed by connecting two separately formed halves, which when connected form an airfoil. The airfoil is usually the main body of the wind rotor blade, which interacts with the wind to cause rotation. Refer to the attached picture again, Figure 4 with Figure 5 Each shows a half piece that can be used to construct an airfoil 48 of a wind turbine blade 10 and provides an example of a rib-reinforced shell 50 according to an embodiment of the present application. Although shown as a half airfoil in the drawings, it should be understood that the present invention is applicable to construction techniques in which half of the airfoil is constructed as a single piece or more than half of the airfoil is constructed as a single piece. As explained in more detail below, the rib-reinforced shell 50 is a shell that includes a cross pattern or a grid or lattice structure substantially...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap