Hydraulic dynamic brake operating system for tractor

A dynamic braking and control system technology, applied in the field of tractors, can solve the problem that the braking pressure cannot meet the braking requirements of the whole vehicle, and achieve the effect of satisfying the braking performance and rigorous system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

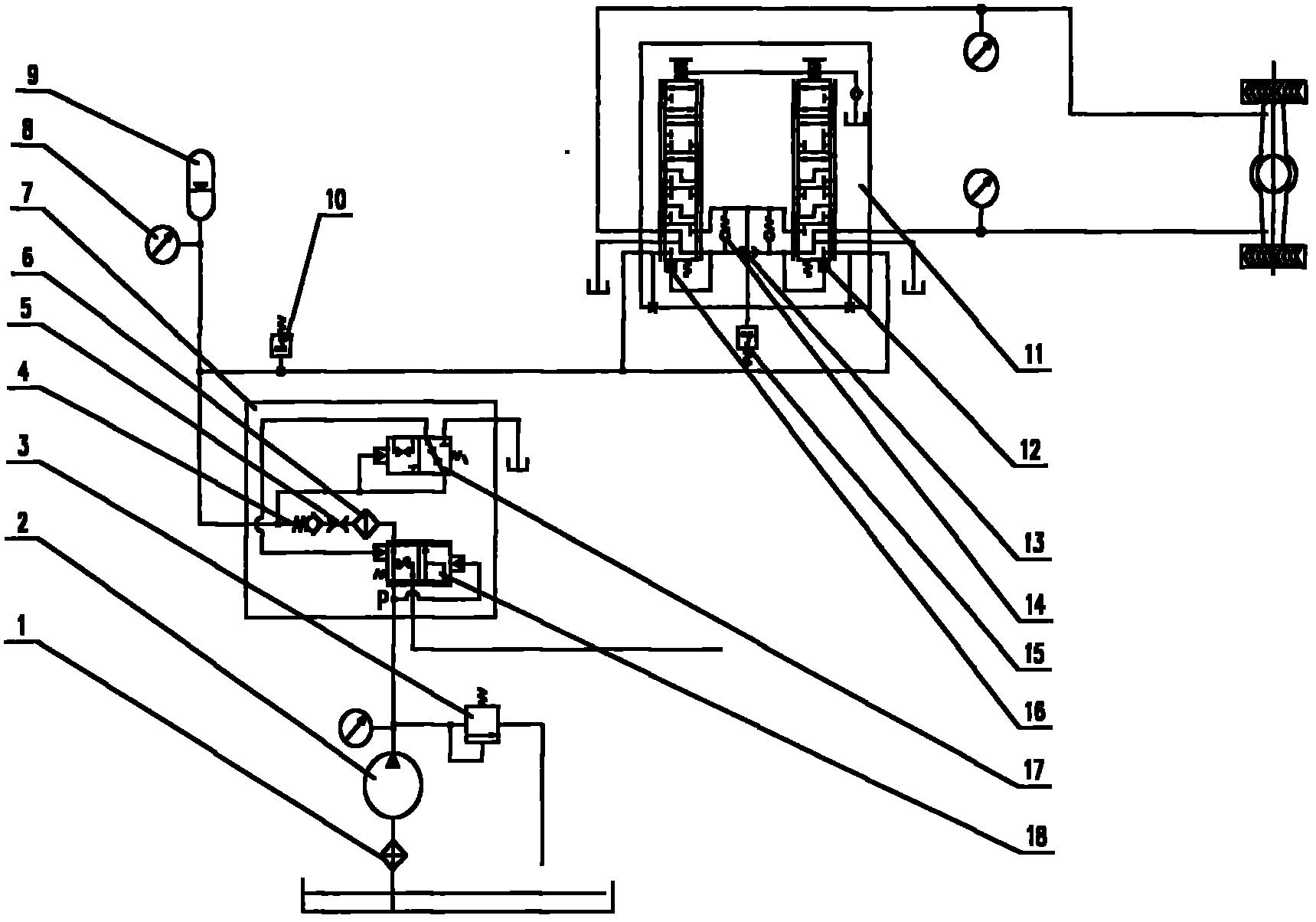

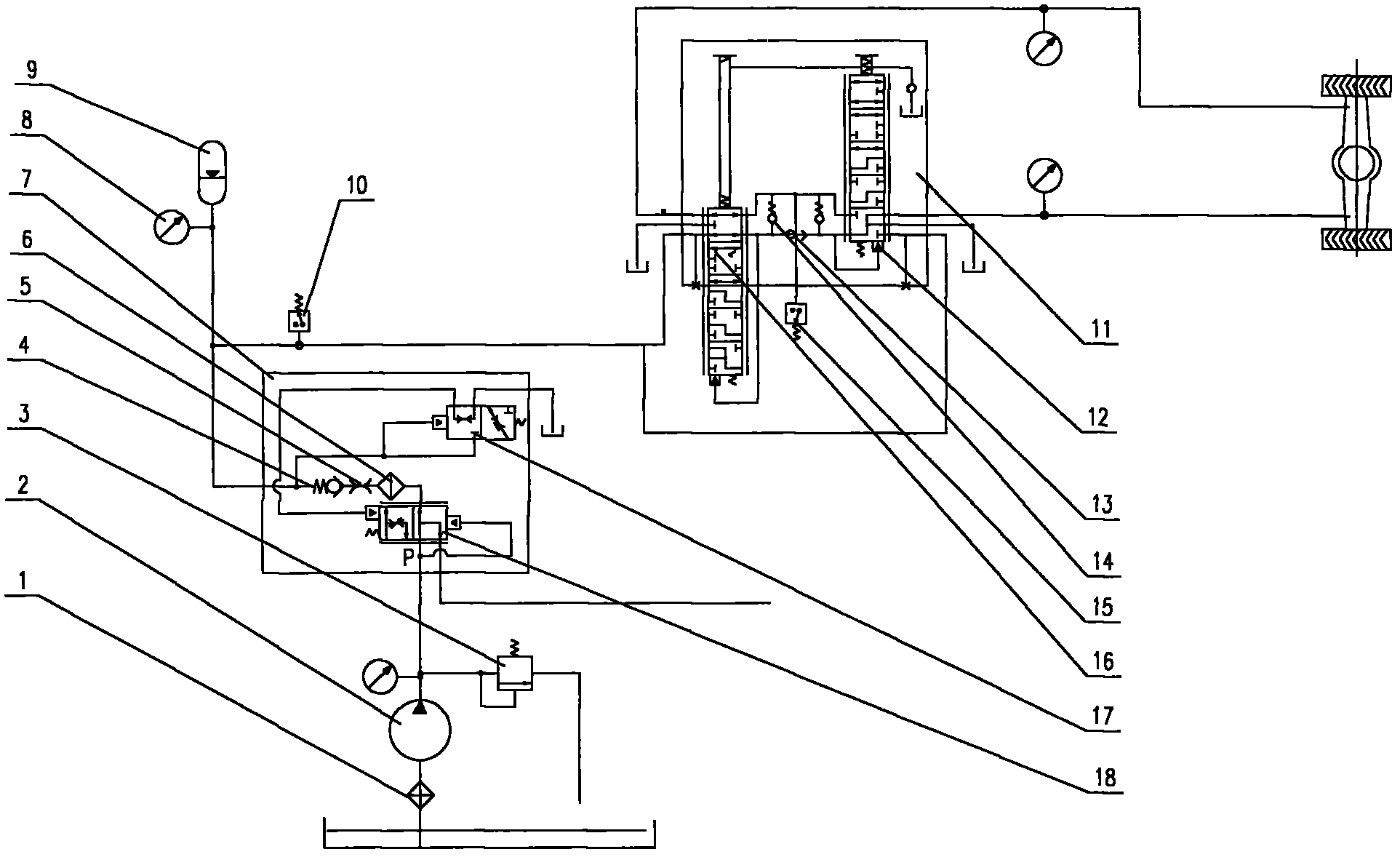

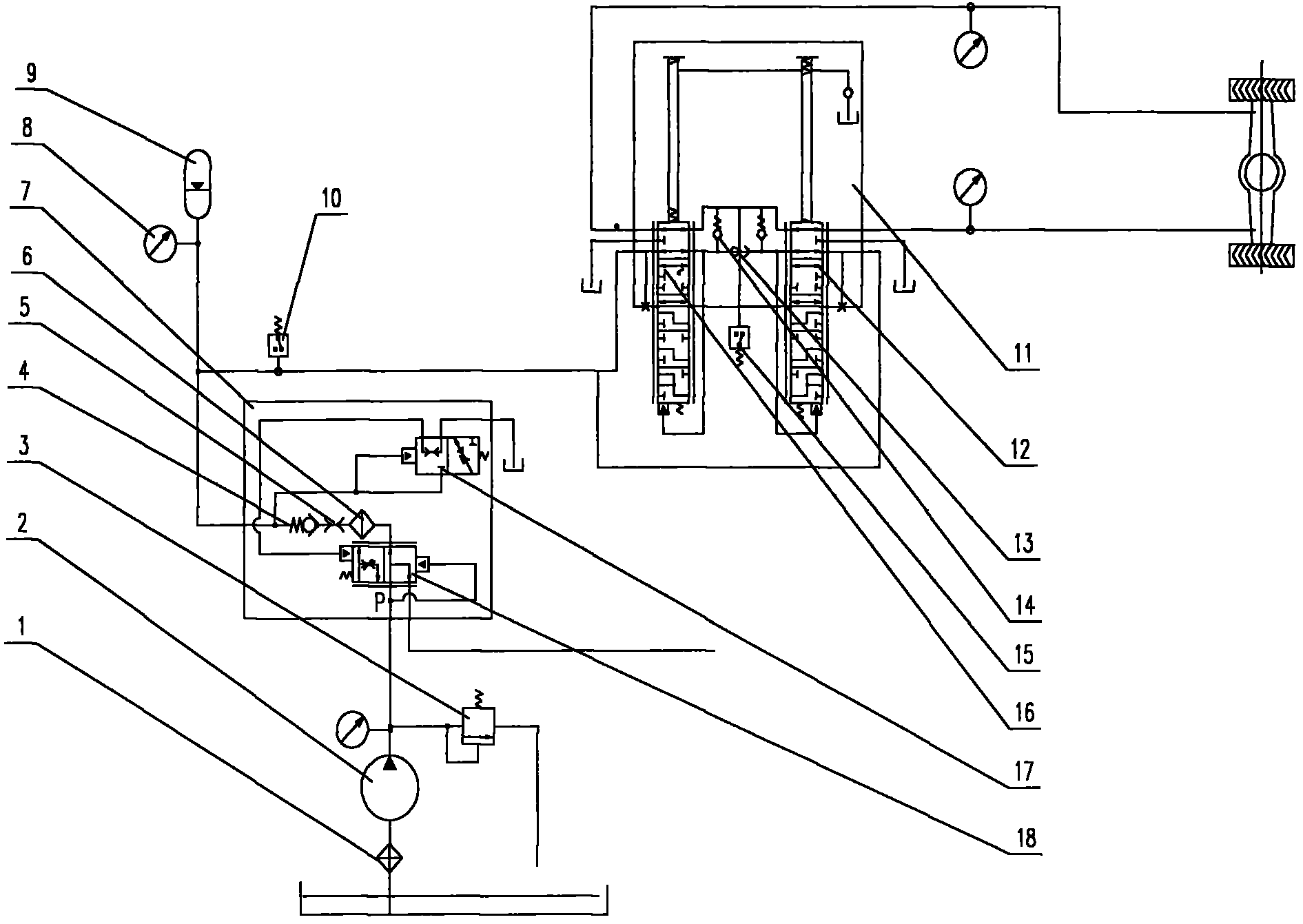

[0012] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1~3 As shown, the tractor hydraulic power brake control system mainly includes oil suction filter 1, oil pump 2, overflow valve 3, check valve 4, throttle port 5, high pressure oil filter 6, liquid filling valve 7, Pressure gauge 8, accumulator 9, brake low pressure alarm switch 10, dual power brake valve 11, left power brake valve 12, shuttle valve 13, one-way valve 14, brake tail light pressure switch 15, right power brake Actuated valve 16, pressure setting part 17, pressure compensator 18; Oil suction oil filter 1 is contained in the oil tank of tractor, and oil pump 2 is installed on one side of tractor; Oil suction oil filter 1 and oil pump 2 are connected by oil pipe. The filling valve 7 is installed on one side of the tractor and connected to the oil pump 2 through a pipeline; the dual power brake valve 11 is installed on the cab floor, and the dual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com