Static discharge test method

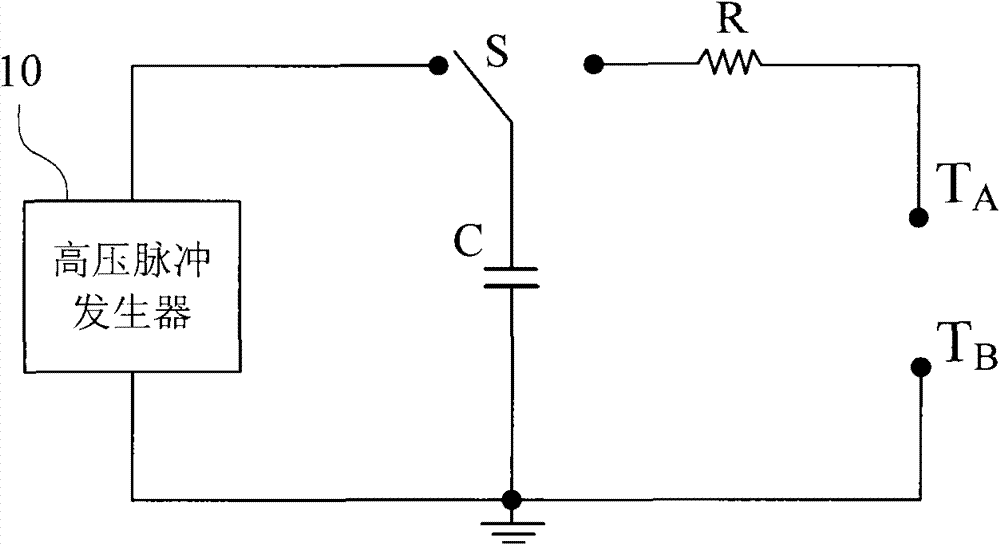

An electrostatic discharge test and test board technology, which is applied in the direction of single semiconductor device testing, etc., can solve the problems of quantity limitation, time-consuming, cost increase, etc., and achieve the effect of saving time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

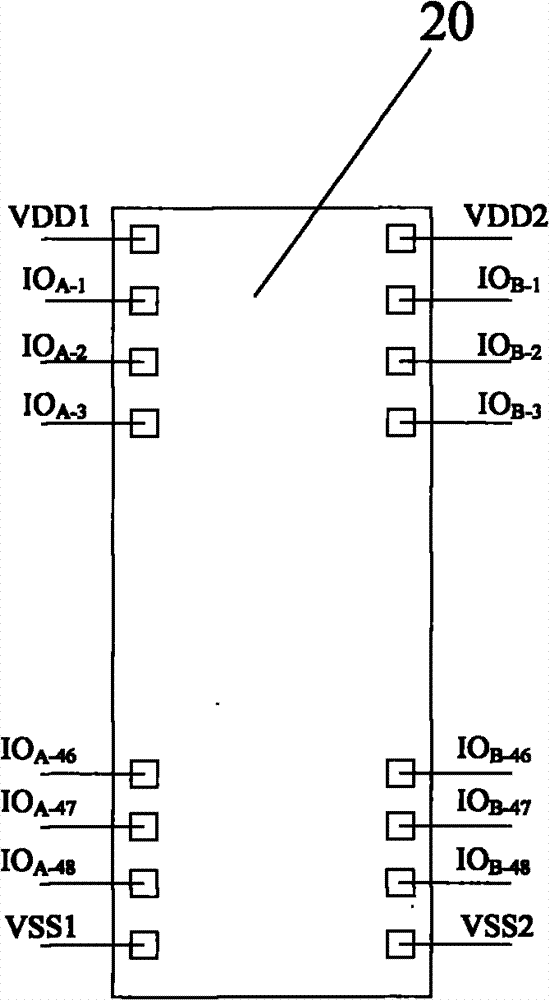

[0023] The inventors have found that with the development of semiconductor technology, the integration of semiconductor devices is getting higher and higher, and there are more and more contact points on the semiconductor device, so that the number of pins on the original test board is smaller than the contact points of the semiconductor device The quantity, can not use the traditional electrostatic discharge test method to test on the test board.

[0024] In order to solve the contradiction in quantity between the pins on the existing test board and the contact points of the semiconductor device to be tested, in view of this, the inventor of the present invention provides a kind of electrostatic discharge test especially for the semiconductor device with many contact points method.

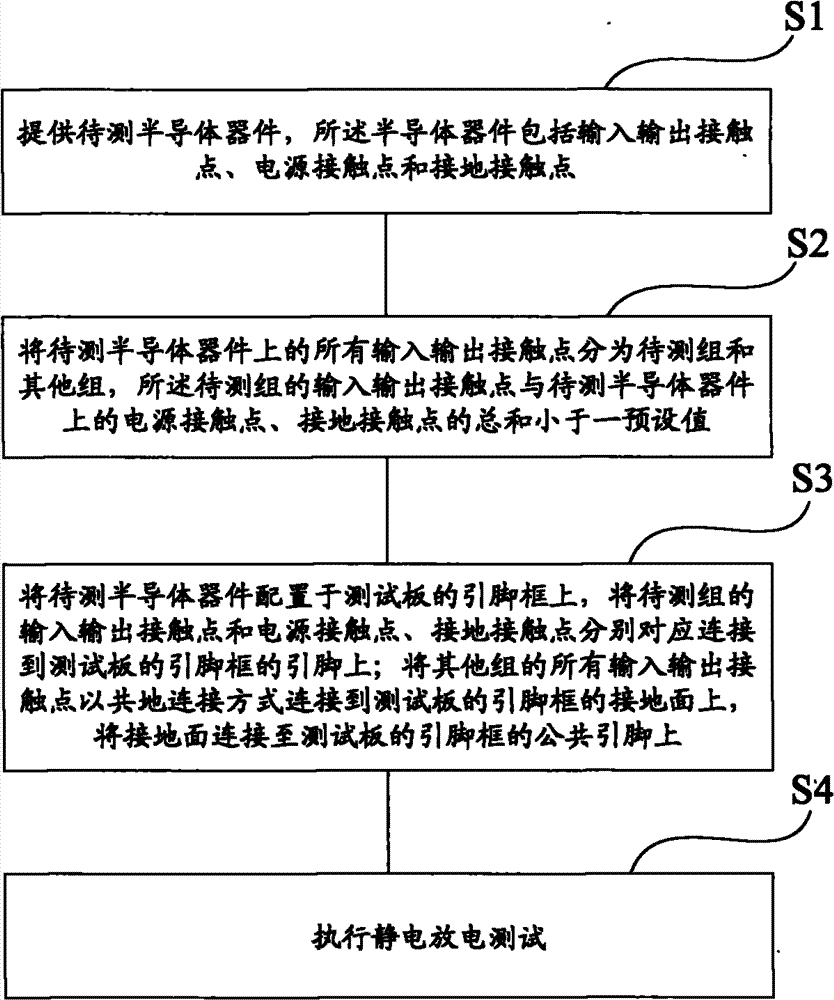

[0025] refer to figure 2 , the embodiment of the present invention provides an electrostatic discharge test method, including:

[0026] Step S1 is executed to provide a semiconductor device to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com