Directing-plane lateral-irradiation solar energy condensation body based on total reflection

A solar concentrating, quasi-planar technology, applied in the field of parallel light concentrating, can solve the problems of easy aging, falling off reflective film, poor self-cleaning performance, etc., and achieve the effect of good light guiding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

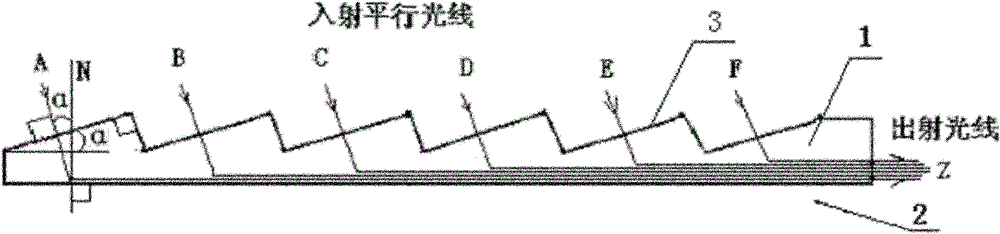

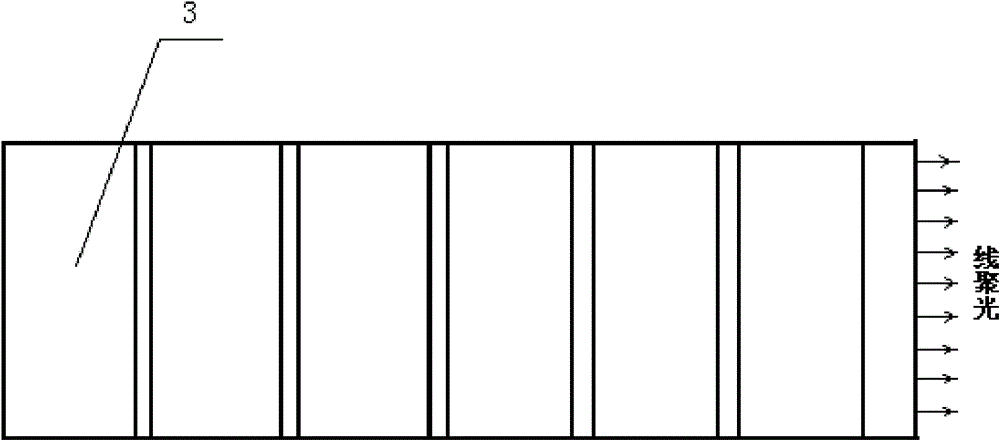

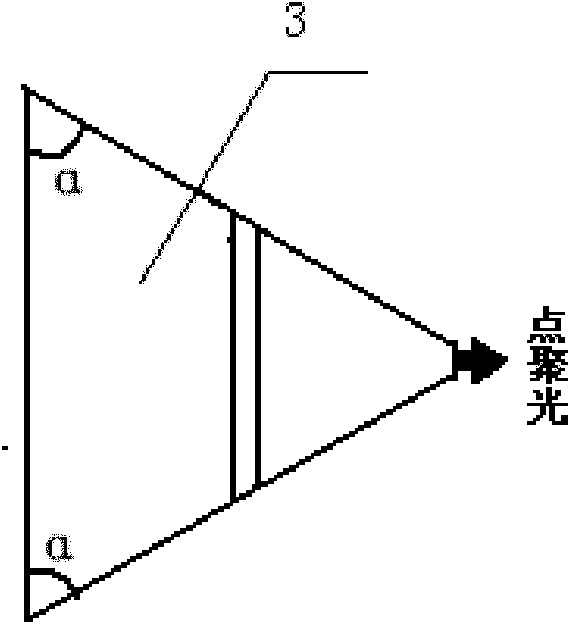

[0015] see figure 1 , the present invention includes an upper quasi-plane composed of mutually parallel sawtooth-shaped slopes 3 made of white glass 1, the sawtooth angle of the parallel sawtooth-shaped slopes 3 is a right angle, and the included angle α between the sawtooth-shaped slopes 3 and the horizontal plane is white The critical angle when total reflection occurs between the lower plane of the glass 1 and the natural environment atmosphere 2. Driven by the high-precision automatic tracking system, it is ensured that the sunlight enters the jagged slope 3 vertically and enters the concentrator; Angle α = 38.7 0, ; and because the angle between the receiving slope and the horizontal plane is the critical angle when sunlight is emitted from the glass concentrator (optical dense medium) to the air (optical sparse medium), so total reflection will occur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com