Defect detecting device

A defect detection and detection device technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve the problems of eye fatigue, reduced detection accuracy, and high misjudgment rate of staff, and achieve Simple structure, high detection efficiency, accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the technical solution of the present invention will be described in detail through specific examples.

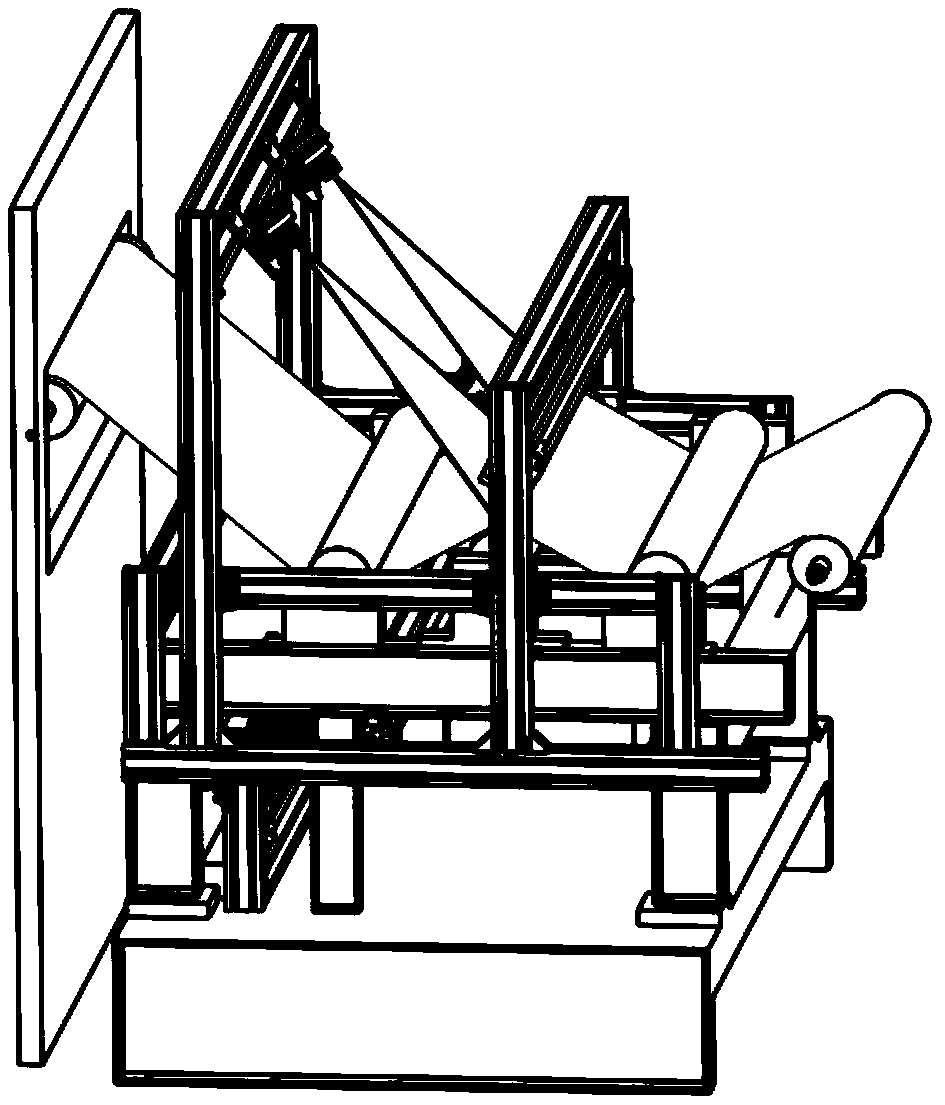

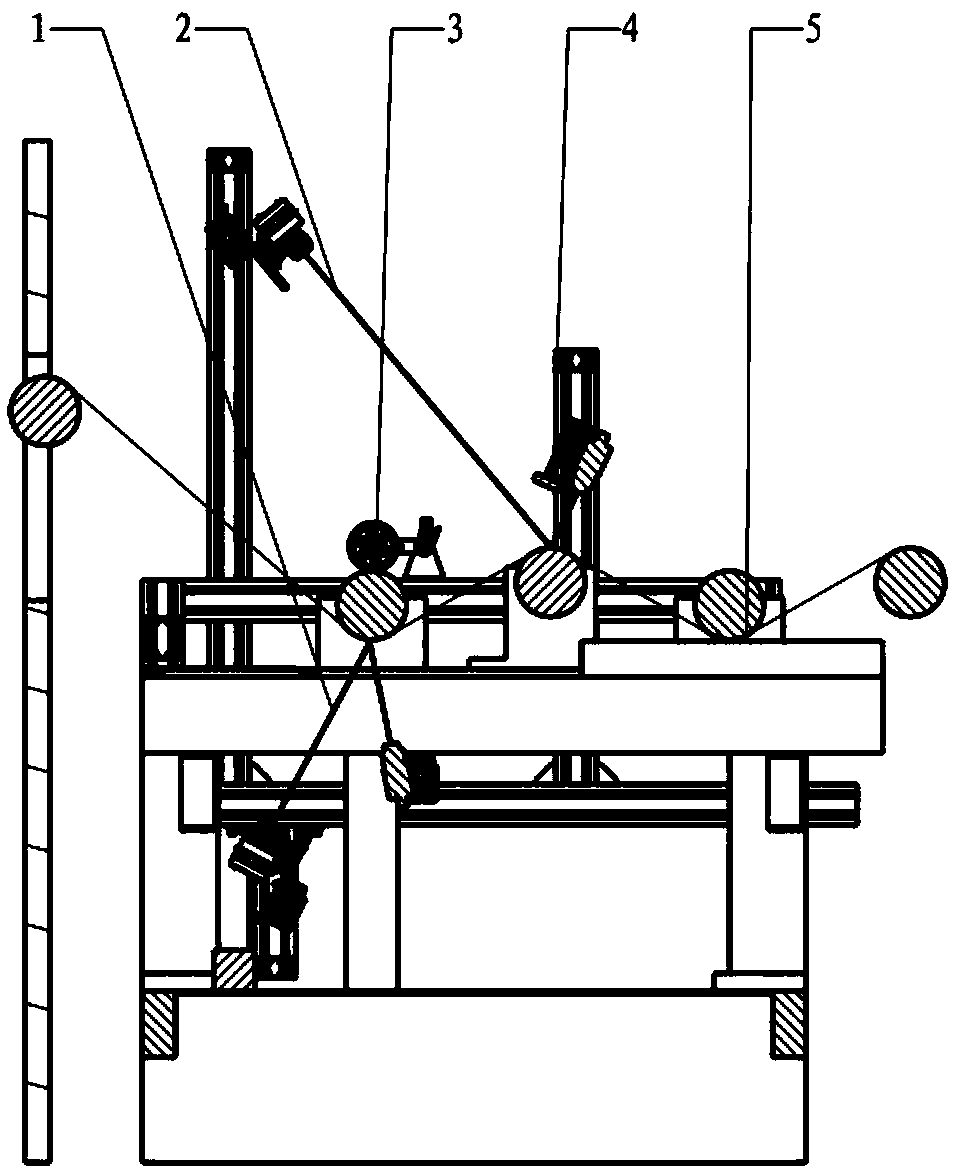

[0026] refer to figure 1 , a defect detection device proposed by the present invention includes a frame, a rough surface detection device 1 and a smooth surface detection device 2; On the rack; the rough surface detection device 1 and the smooth surface detection device 2 can move relative to the position of the object to be tested, so as to detect the defects of the object to be tested.

[0027] The frame includes a profile frame 4 on which both the rough surface detection device 1 and the smooth surface detection device 2 can be moved and fixed.

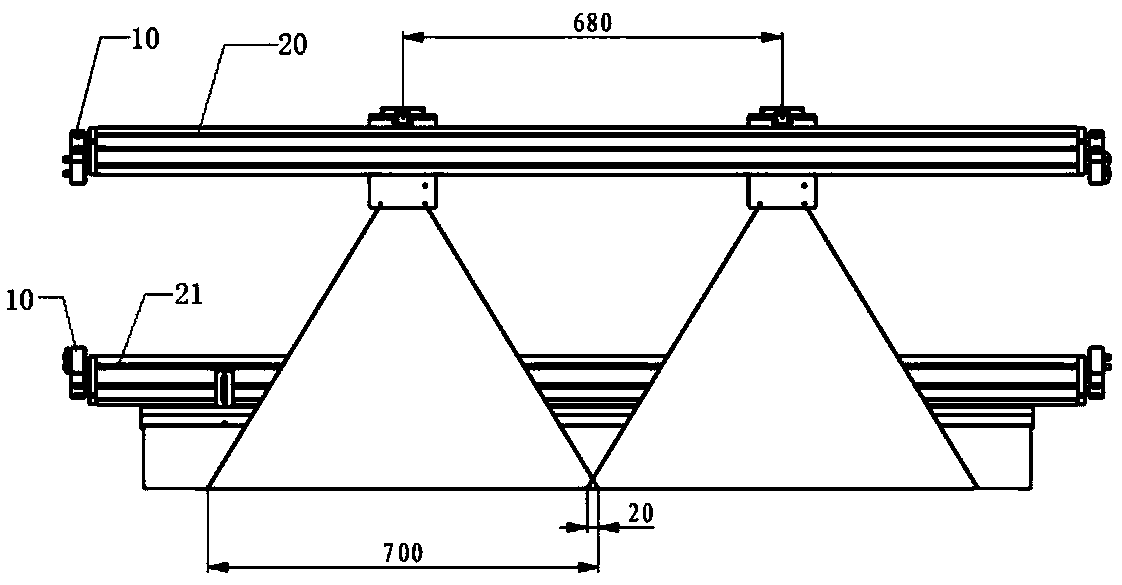

[0028] Further, the light surface detection device 2 includes a first camera assembly, a first light source assembly and a first adjustment seat 10, the first camera assembly includes a light surface camera 6, a light surface camera fine-tuning mechanism 7 and a light surface camera rotation mechanism 20, the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com