Vibration actuator

一种振动致动器、振动方向的技术,应用在电气元件、机电装置等方向,能够解决耐冲击性低、构造复杂化等问题,达到提高耐跌落冲击性、实现薄型化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

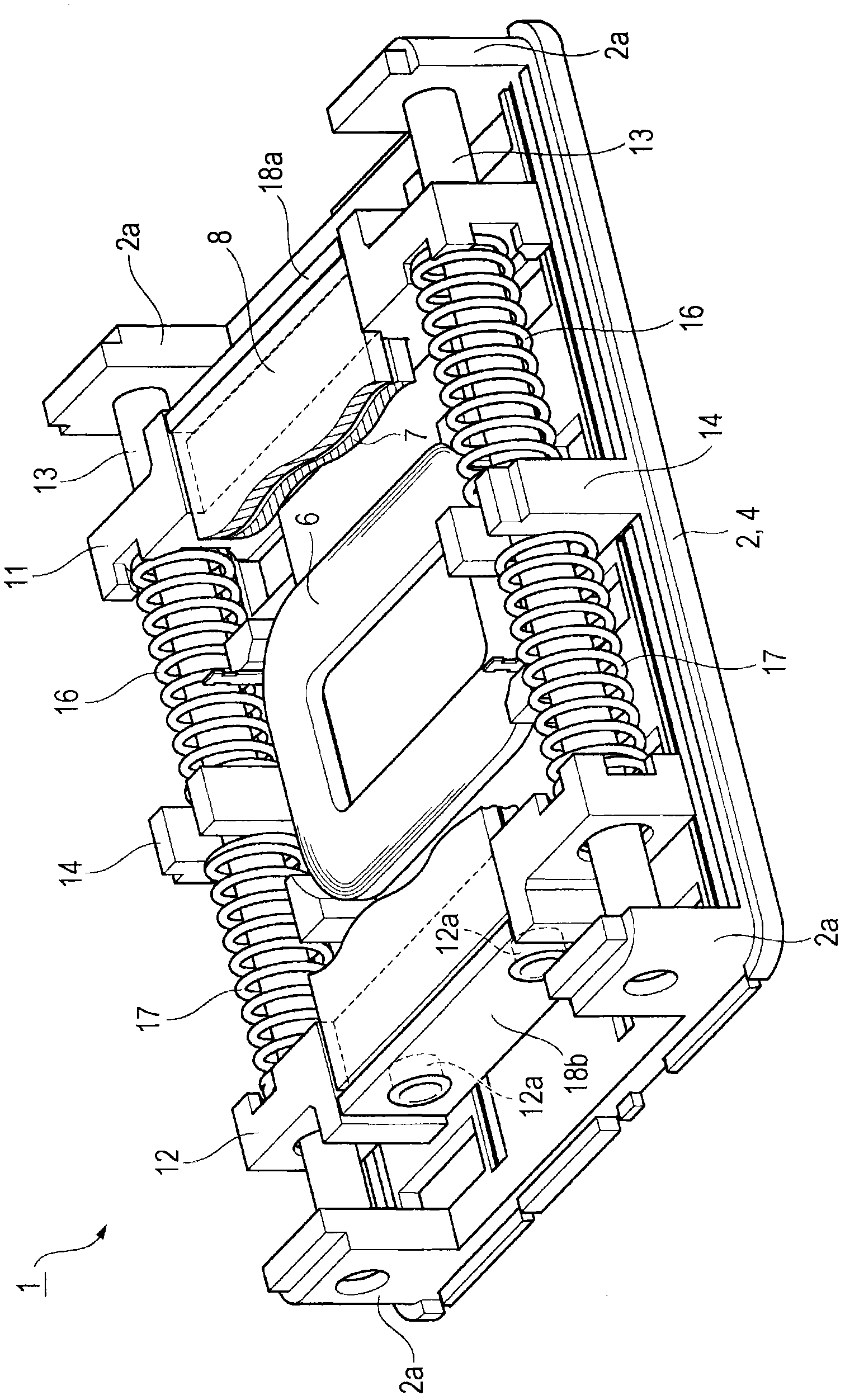

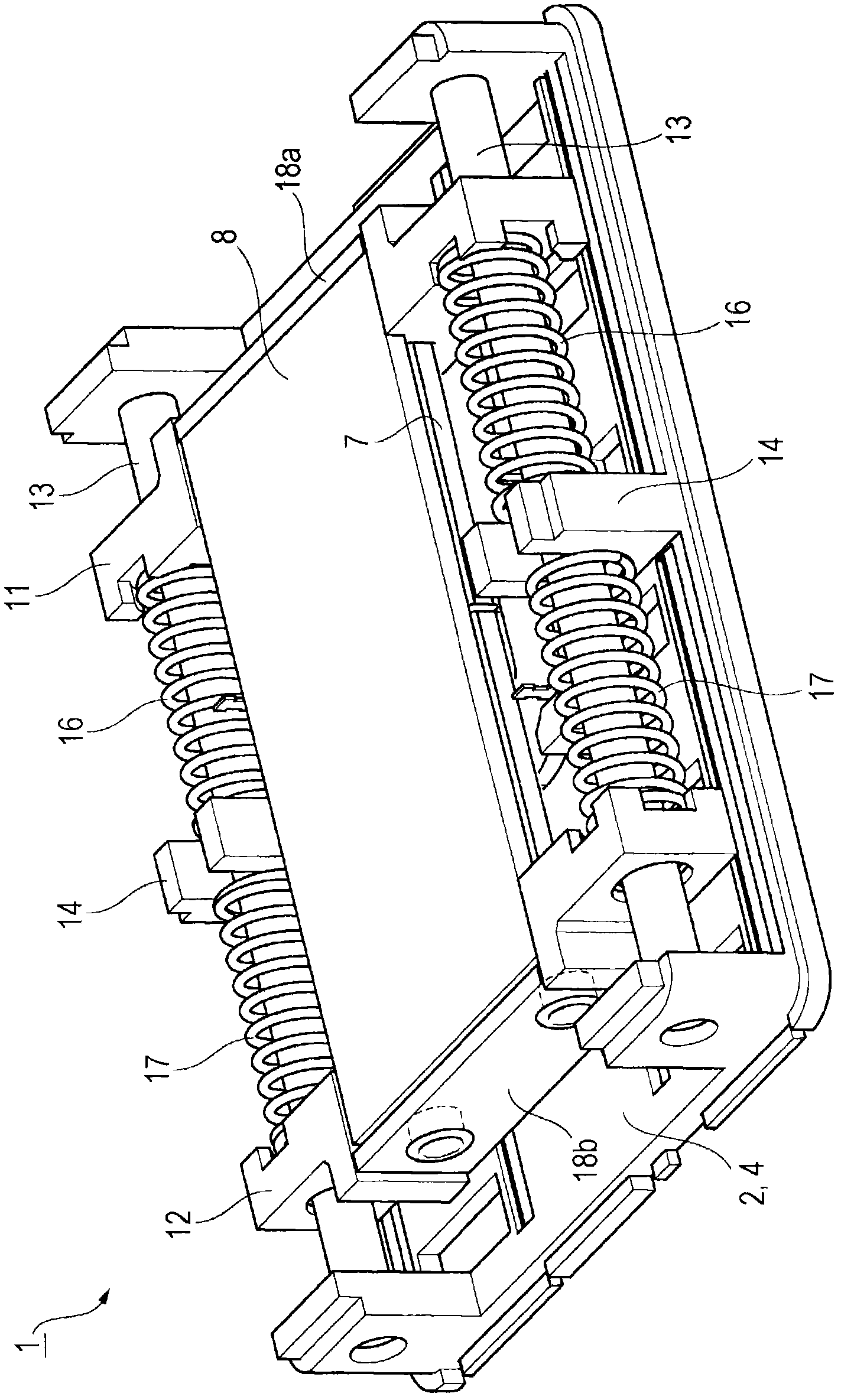

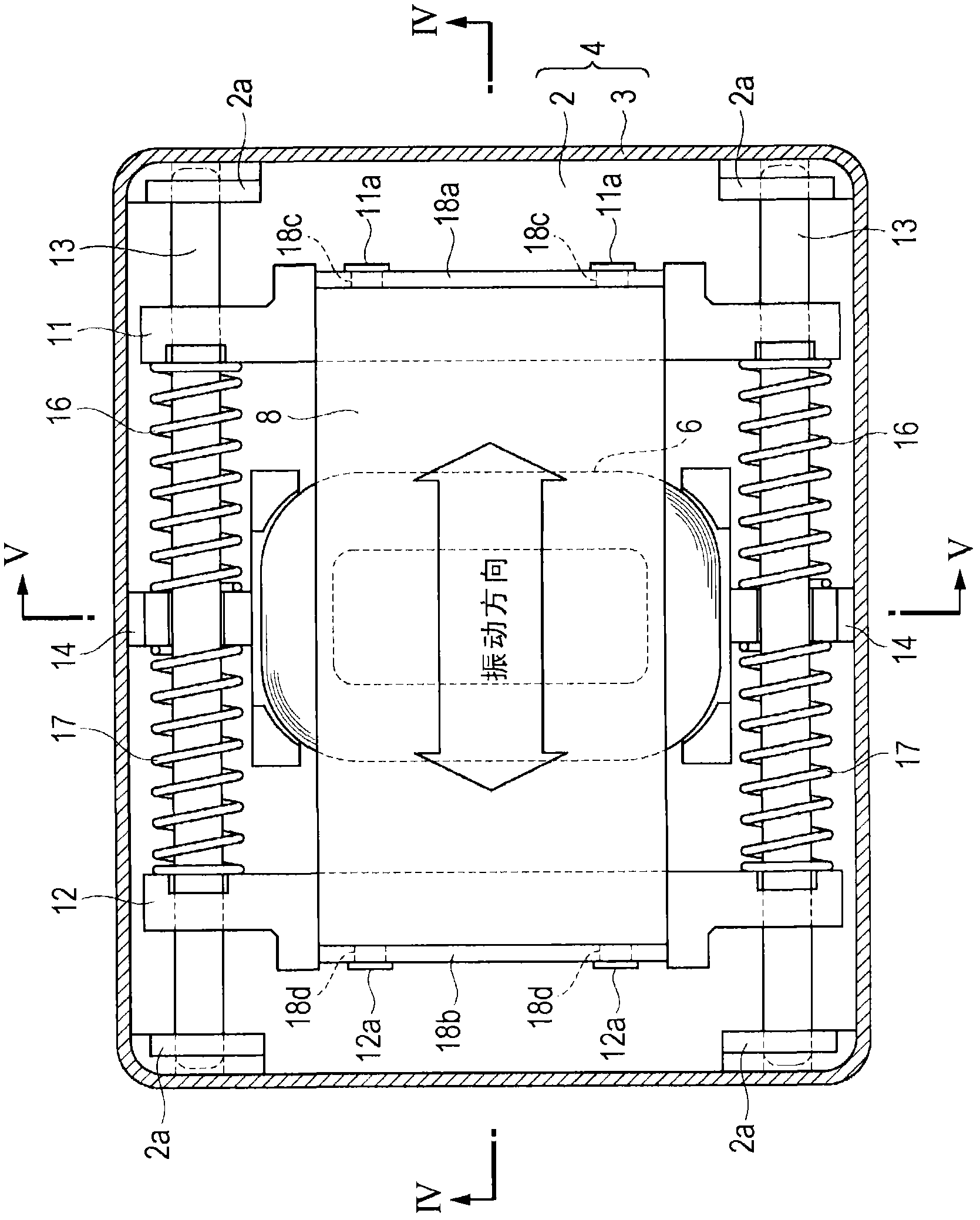

[0048] Hereinafter, preferred embodiments of the vibration actuator of the present invention will be described in detail with reference to the drawings.

[0049] Such as Figure 1 to Figure 5 As shown, the vibration actuator 1 has a flat frame 4 including a base plate 2 and a cover 3 . Inside the housing 4 are accommodated an annular flat coil 6 fixed to the base plate 2 and a plate-shaped flat magnet 7 arranged to face the coil 6 . The magnet 7 is formed by two magnet parts 7a and 7b whose one plane side is an N pole and the other plane side is an S pole. The magnet 7 is configured such that the N pole of one magnet portion 7a faces the S pole of the other magnet portion 7b on a plane, and the side surface of the magnet portion 7a and the side surface of the magnet portion 7b are bonded together with an adhesive. . Furthermore, the magnet 7 may be formed by magnetizing one magnetic plate.

[0050] Furthermore, the coil 6 is connected to the terminal electrode 5 provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com