All-weather zero-discharge outdoors-sand-making-system composite vibrating screen mechanism and anti-blocking method

A compound vibration, zero-emission technology, applied in chemical instruments and methods, sieves, solid separation, etc., can solve problems such as inability to produce, pollute, and fail to solve the powder method environment, reduce power consumption, ensure physical health, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

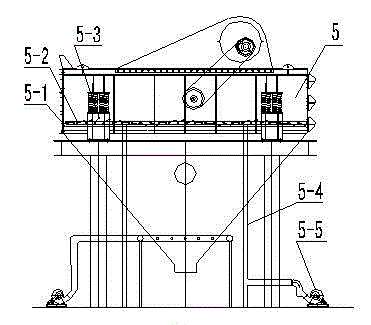

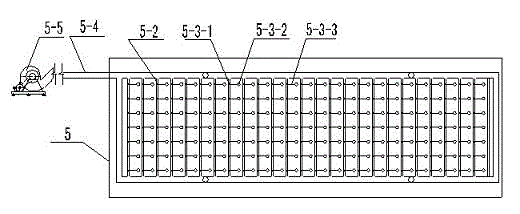

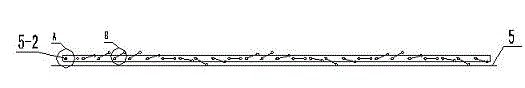

[0019] Embodiment 1: with reference to attached Figure 1-5 . Composite vibrating screen mechanism for all-weather zero-emission open-pit sand making system, which includes a vibrating screening mechanism 5. The vibrating screen in the vibrating screening mechanism 5 is composed of three layers of screens. The apertures of the screens are different, and become smaller successively from top to bottom. A blowing device is arranged above the surface of the third layer of screens. The air duct of the blowing device is provided with a plurality of bouncing balls 5-2. The top of the feed inlet is provided with a water mist pressure dust cover, and the discharge port of the vibration screening mechanism 5 is provided with a discharge dust suction cover 5-9.

[0020] The top of the feeder 2 is provided with a water mist nozzle 2-1 or a water mist pressure dust cover, and the water mist pressure dust cover is composed of a casing 2-2 and a water mist nozzle 2-1, and the water mist noz...

Embodiment 2

[0026] Embodiment 2: refer to attached Figure 6 . On the basis of Example 1, the sand making method of the all-weather zero-emission open-pit sand making system, stone or tailings enter the feeder 2 from the feed port 1 and are transported by the feeder 2 into the feed port of the cone sand making machine 3, When the cone sand making machine 3 crushes the stone, the water mist nozzle or water mist pressure dust cover located above it covers the dust generated in the crushing process so that it cannot fly. At the same time, the crushed surface of the stone and the crushing process The generated heat evaporates the water produced by the water mist, so that the stones entering the vibrating screening mechanism 5 from the discharge port of the cone sand making machine are stones with low water content. The first layer of the vibrating screening mechanism 5 The sieve screen screens out the stones larger than the set diameter and recycles them into the cone sand making machine by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com