Production equipment and process for laminating film on fibers

A technology of production equipment and production technology, which is applied in the field of fiber-coated production equipment and its production technology, can solve the problems of difficulty in meeting the practical needs of users, low production efficiency, inconvenient use, etc., and achieve convenient and practical production technology, simple structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

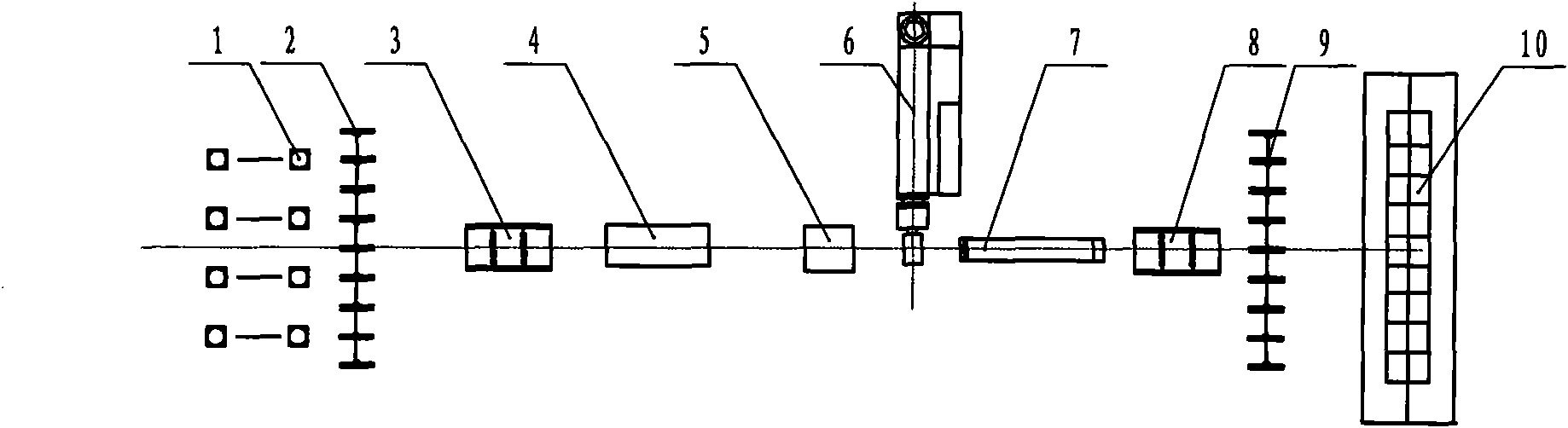

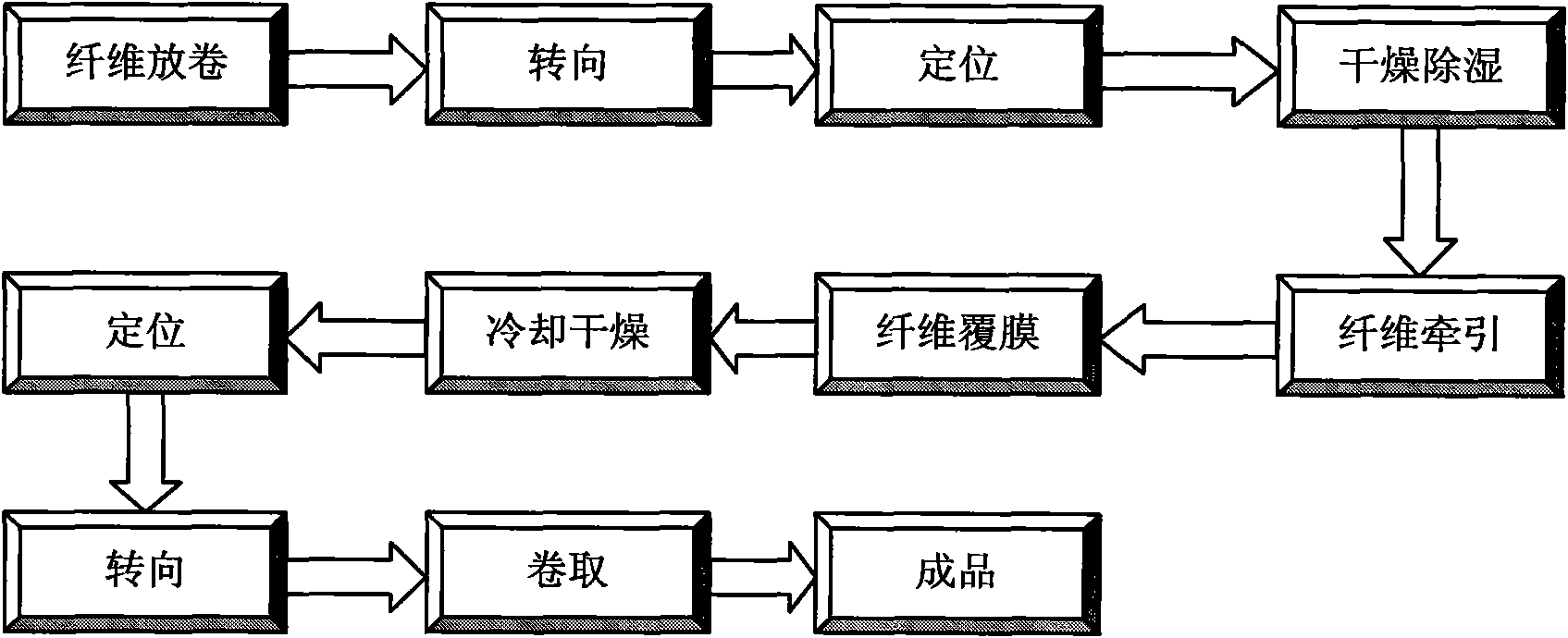

[0024] The schematic diagram of the production equipment of the present invention is as figure 1 As shown, the production equipment of the fiber coating of the present invention includes at least one set of fiber unwinding device 1 for fiber unwinding and tension control, at least one set of fiber turning and positioning device for fiber turning and positioning, at least one set of Drying and dehumidification device 4 for drying and dehumidification, at least one set of film covering device 6 for film covering, at least one set of cooling and drying device 7 for cooling and drying the coated fiber, at least one set of film coating device for winding fiber-coated products Fiber winding device 10, wherein the fiber turning and positioning device is placed between the fiber unwinding device 1 and the drying and dehumidifying device 4, the coating device 6 is placed beside the drying and dehumidifying device 4, and the cooling and drying device 7 is placed on the coating device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com