08 BHC double-row roller chain

A technology of rollers and chains, applied in the direction of transmission chains, etc., can solve the problems of low tensile strength, short service life, small shape, etc., and achieve the effect of improving wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

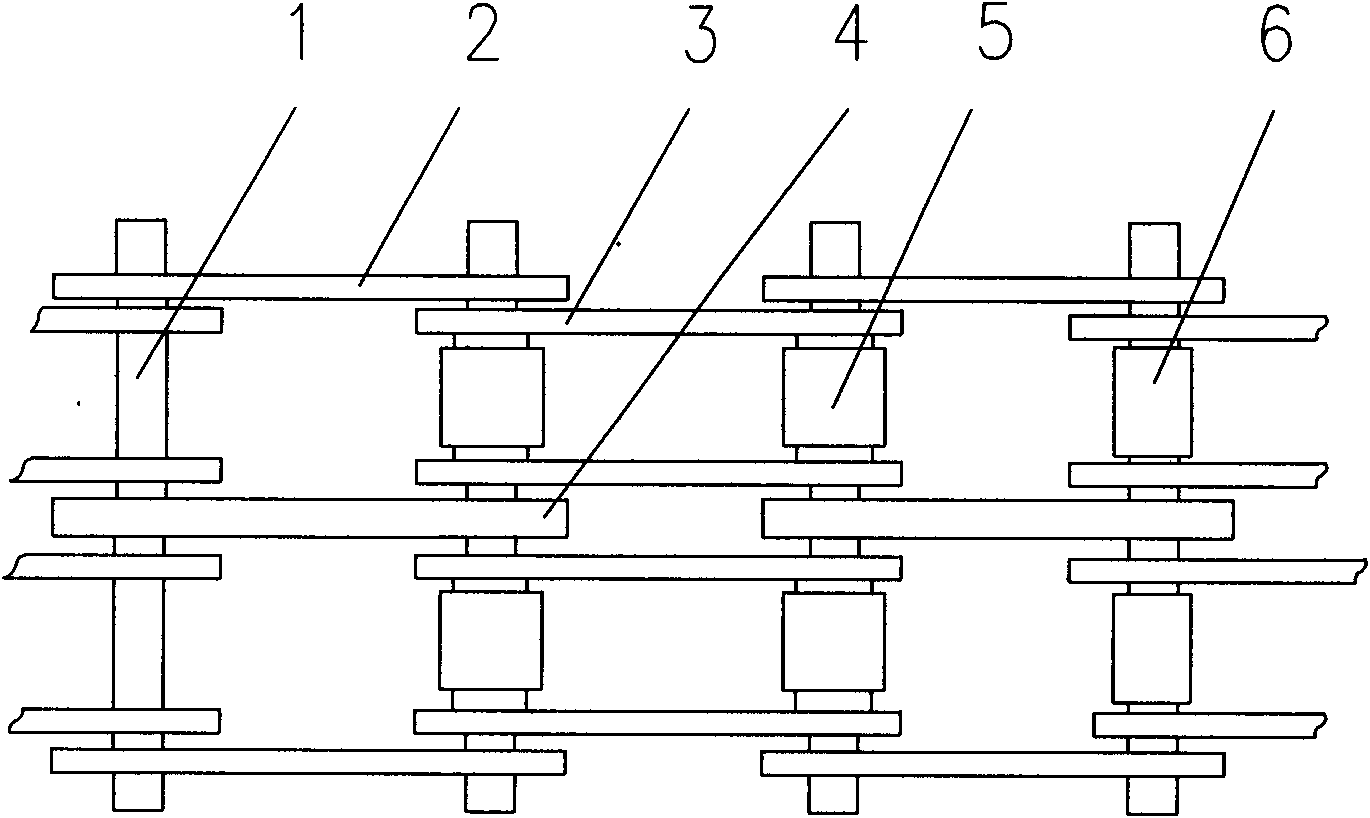

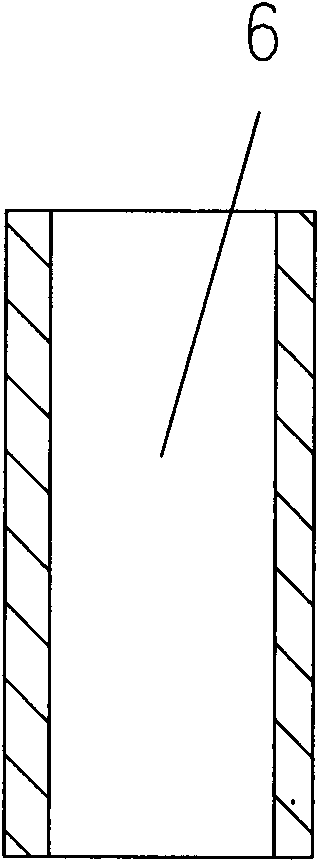

[0029] As shown in each figure: a 08BHC double row roller chain. It comprises pin shaft 1, outer chain plate 2, inner chain plate 3, middle chain plate 4, roller 5, sleeve 6.

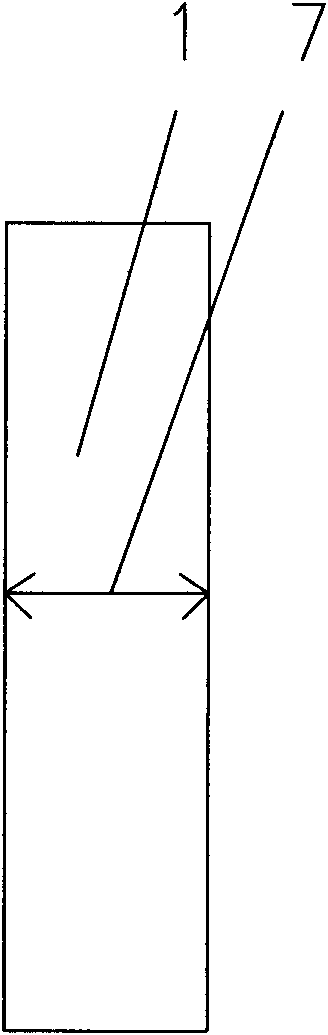

[0030] The diameter of the pin shaft 7 is enlarged from the original 4.45 mm to 4.63 mm.

[0031] The diameter 8 of the inner hole of the outer chain sheet is enlarged to 4.48 millimeters from the original 4.38 millimeters. The diameter 9 of the waist of the outer chain piece is enlarged from the original 8 mm to 8.5 mm. The diameter 10 of the outer circle of the outer chain sheet is enlarged from the original 10.5 millimeters to 11 millimeters. Outer chain piece thickness 11 expands to 2 millimeters from original 1.6 millimeters.

[0032] The thickness 12 of the inner chain sheet is expanded from the original 1.6 millimeters to 2 millimeters.

[0033] The inner hole diameter 13 of the middle chain sheet is enlarged from the original 4.48 mm to 4.65 mm. The waist diameter 14 of the middle chain pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com