Magnetic liquid sealing process researching device

A magnetic liquid, non-magnetic technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of inaccurate and intuitive magnetic liquid seal observation and measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

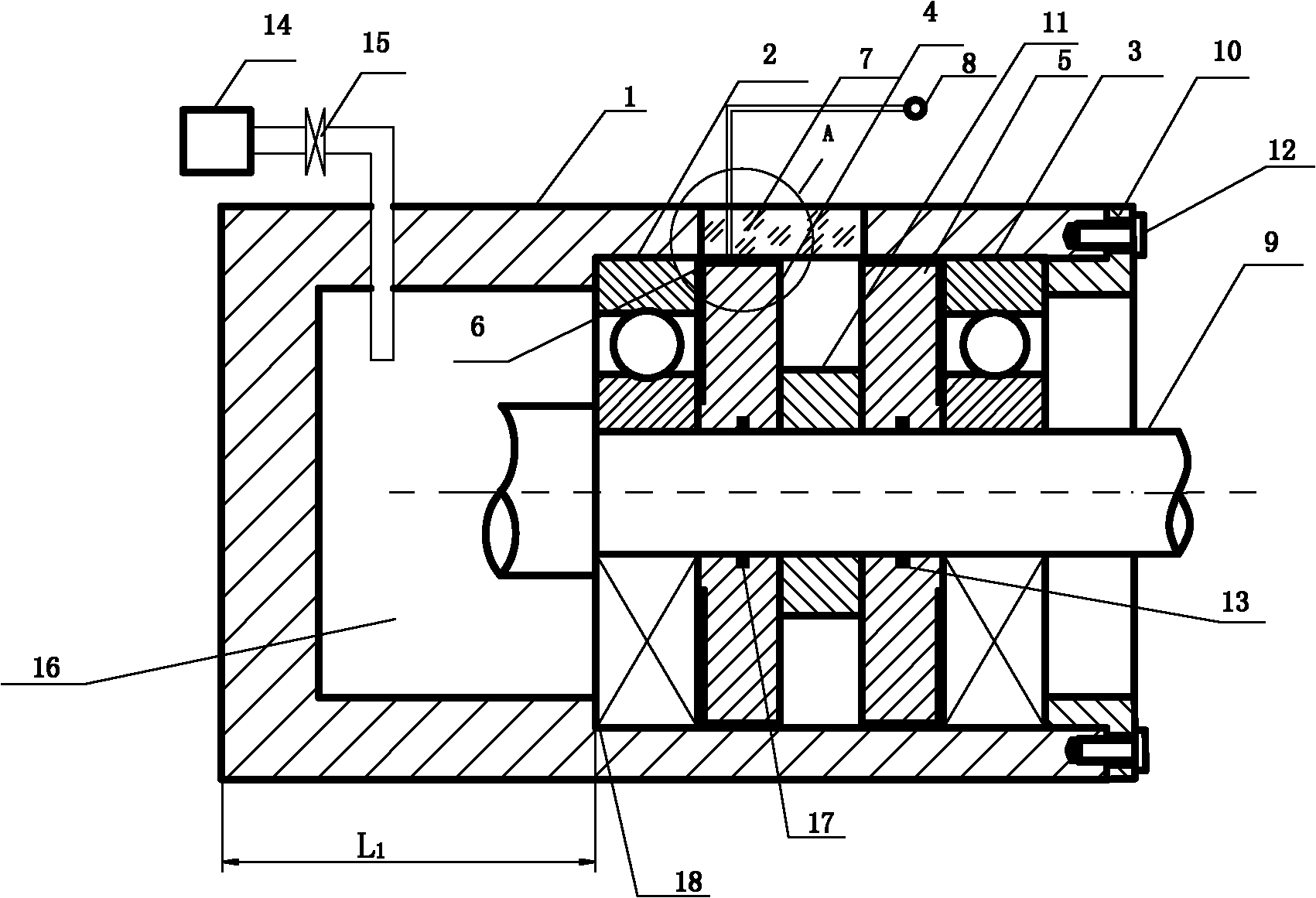

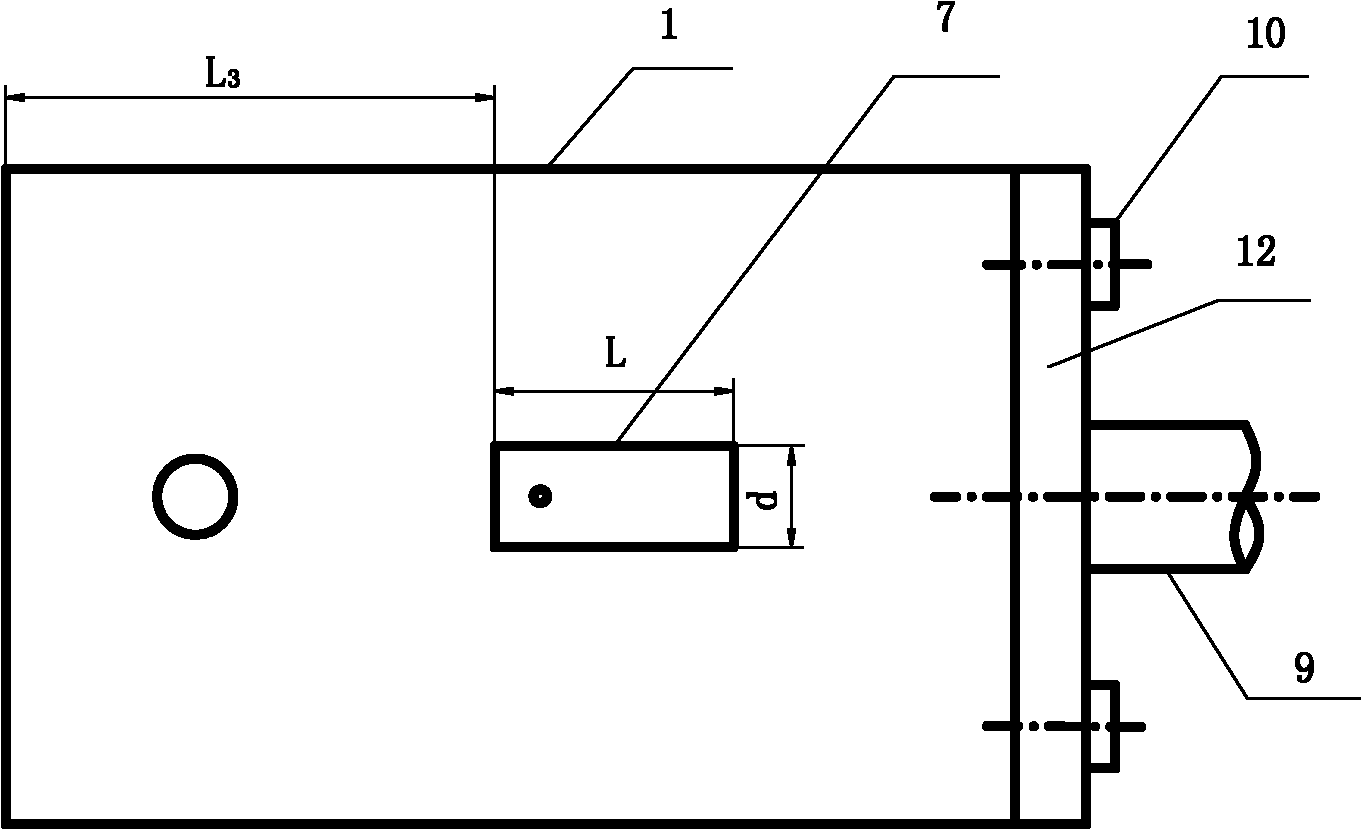

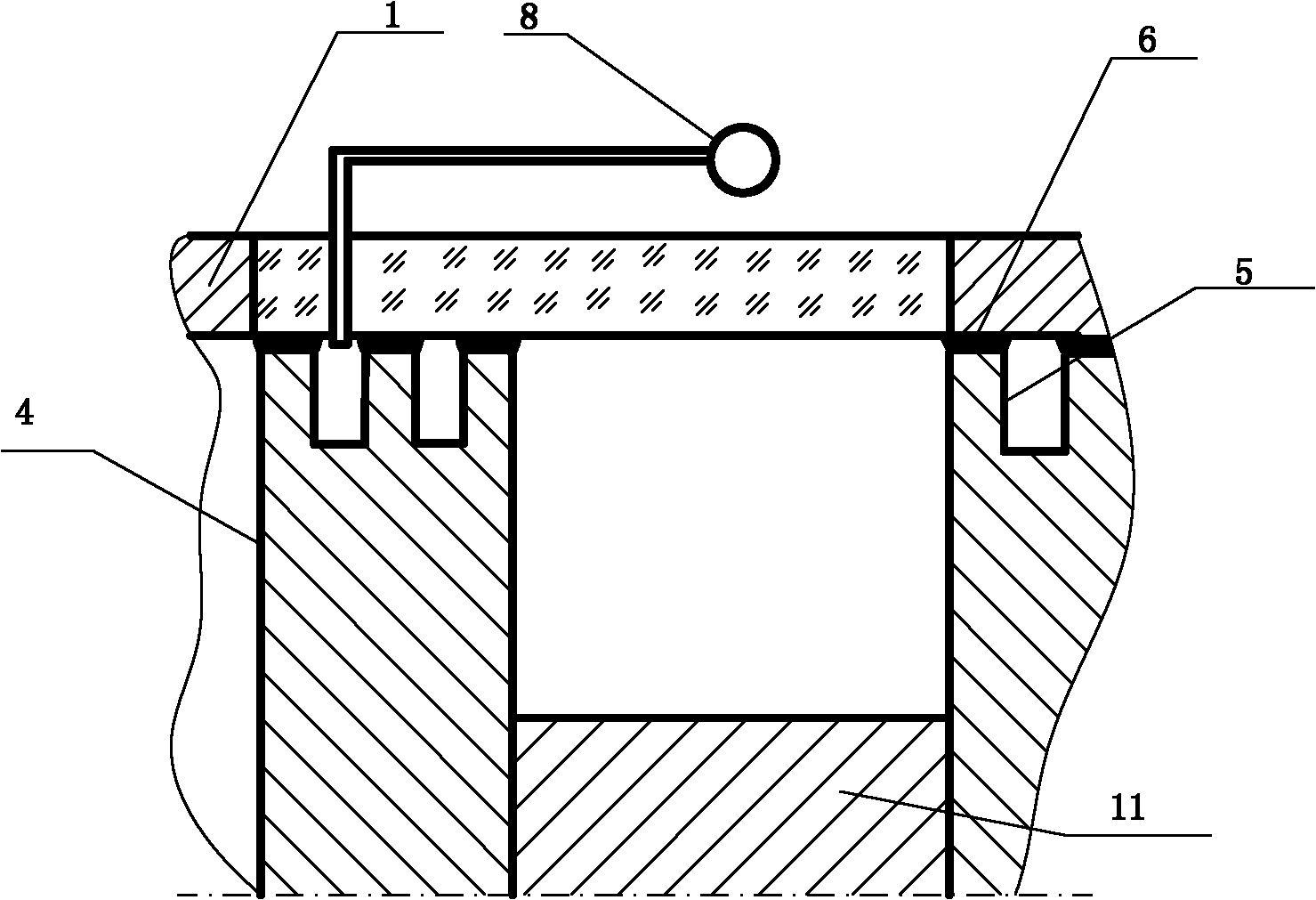

[0020] The present invention will be further described in conjunction with accompanying drawings.

[0021] A magnetic liquid sealing process research device, see figure 1 , 2 , 3, the device includes: outer casing 1, first bearing 2, second bearing 3, first pole shoe 4, second pole shoe 5, magnetic liquid 6, transparent glass block 7, barometer 8, non-magnetic shaft 9, Flange 10, permanent magnet 11, screw 12, first rubber sealing ring 13, vacuum pump 14, valve 15, second rubber sealing ring 17; the connection of the above-mentioned parts:

[0022] The transparent glass block 7 is inlaid and sealed on the outer cover 1 .

[0023] The vacuum pump 14 communicates with the sealed space 16 through the pipeline and the valve 15 on it, and is connected to the jacket 1 in a sealed manner.

[0024] The barometer 8 communicates with the tooth groove of the first pole shoe 4 through a pipeline, and is sealed and connected to the transparent glass block 7 .

[0025] Insert the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com