Half-wave plate, optical pickup device, polarization conversion element, and projection display device

一种波长板、偏振面的技术,应用在投影型显示装置领域,能够解决石英板强度降低、振荡激光波长漂移、相位差变化量变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0112] Figure 6 (A), Figure 6 (B) schematically shows an embodiment of the 1 / 2 wavelength plate of the present invention. The 1 / 2 wave plate 1 of this embodiment is formed of a single quartz wave plate with a constant thickness. The quartz wave plate as Figure 6 As shown in (C), the cutting angle β defined by the normal line erected on its incident surface 1a (or exit surface 1b) and the crystal optical axis (Z axis) of quartz is in the range of 5°≤β≤30° The inner quartz plate is cut out. In particular, by setting the cutting angle within this range, as a single-plate 1 / 2 wave plate, it is possible to process a quartz wave plate having a thickness sufficient for processing and handling without difficulty in manufacturing.

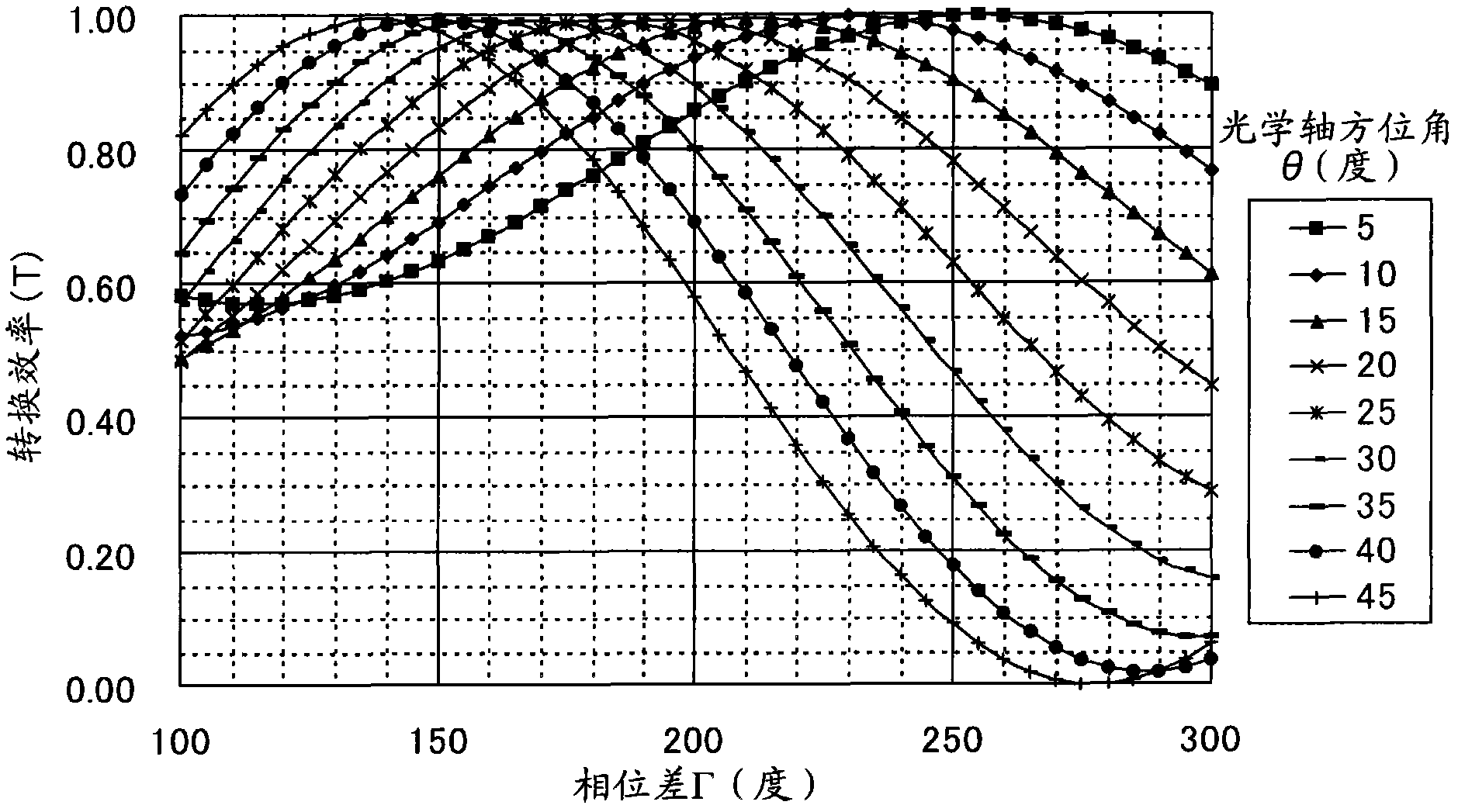

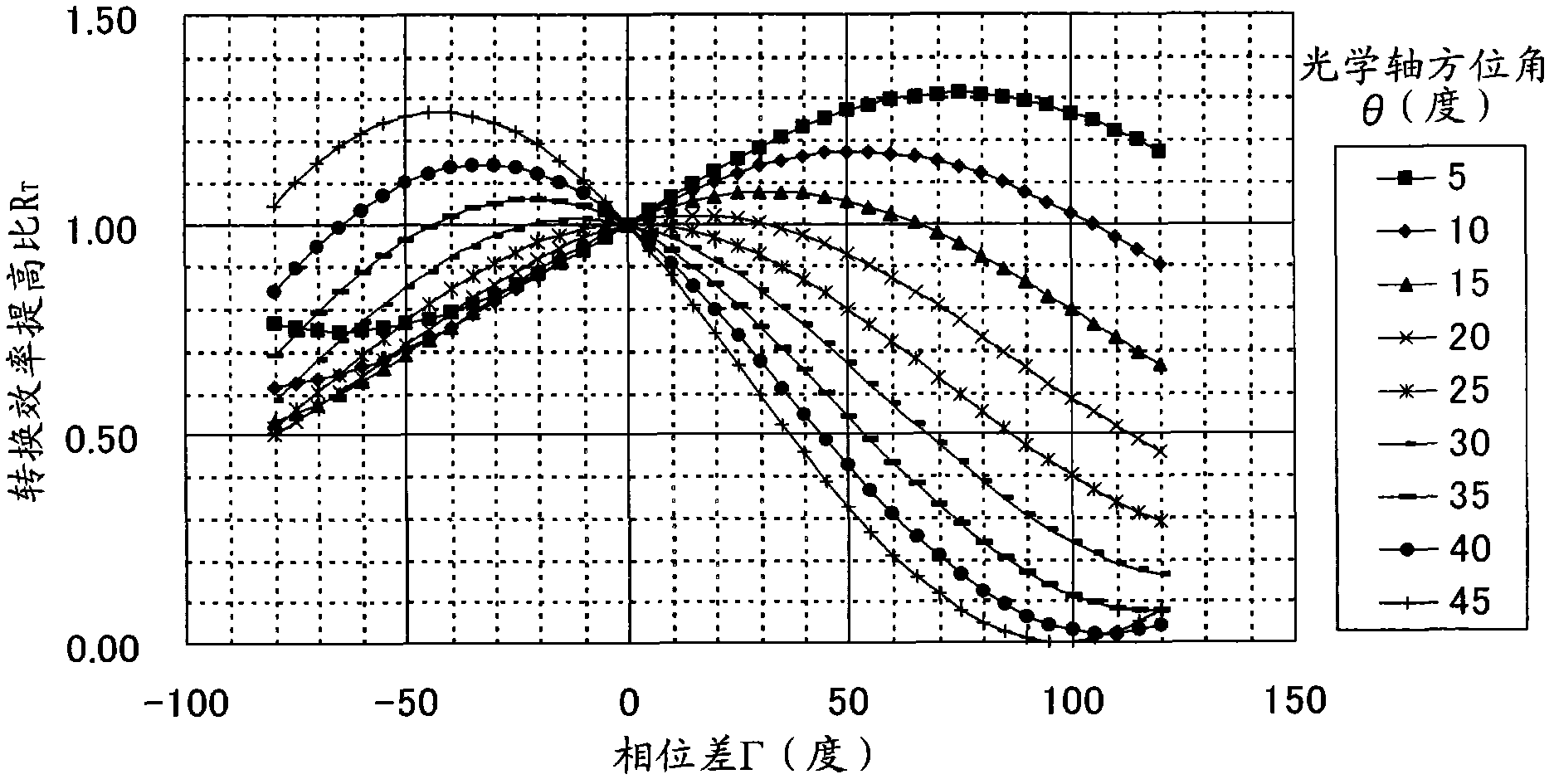

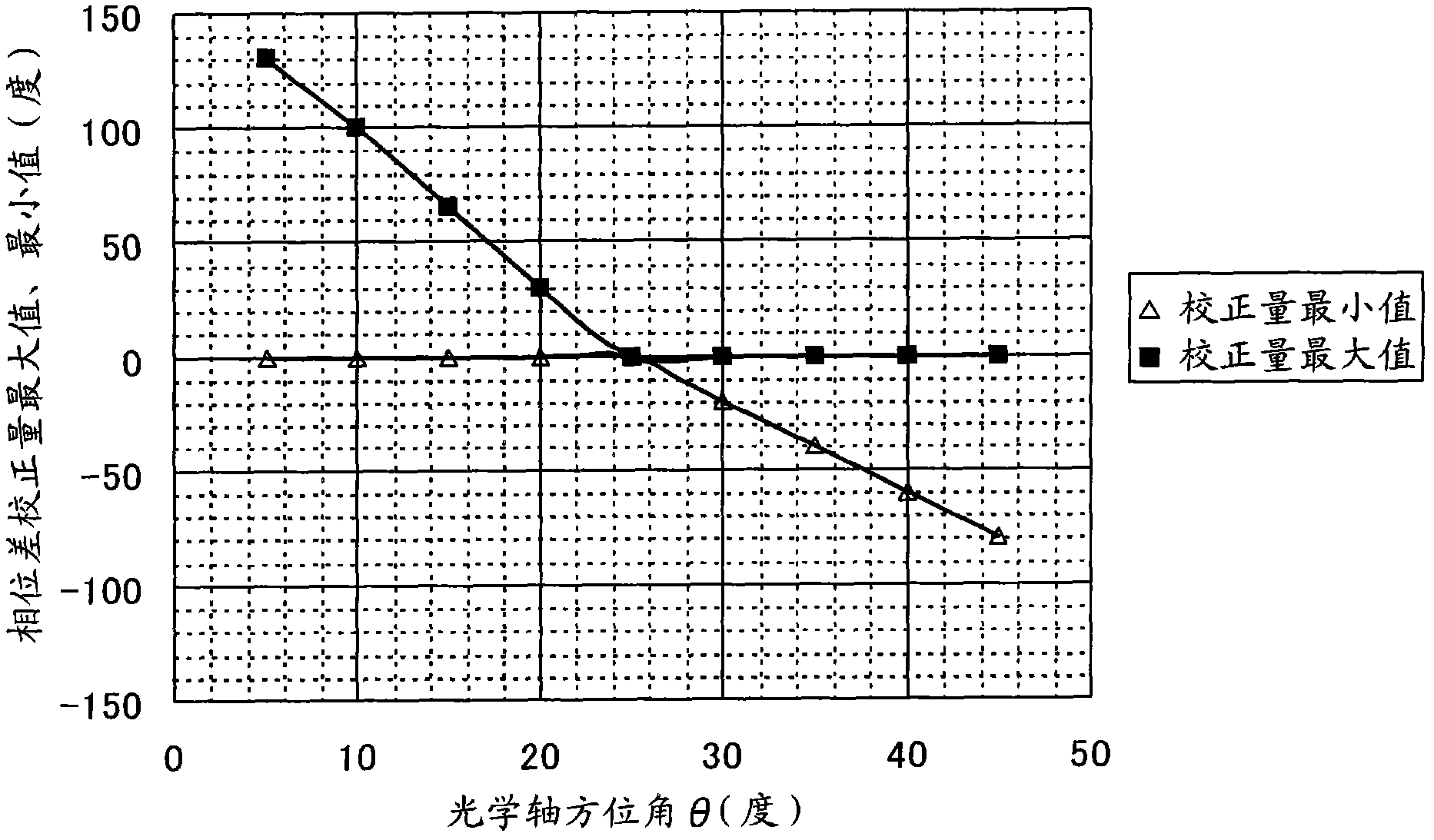

[0113] Let the standard phase difference be 180°, set the phase difference correction amount relative to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com