Holographic anti counterfeit polyurethane membrane

A holographic anti-counterfeiting, polyester base film technology, applied in the field of polyester film, can solve the problems of high price of molding medium, lower efficiency, increase production cost, etc., to save the process of molding medium and coating molding medium, and reduce production. cost, efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

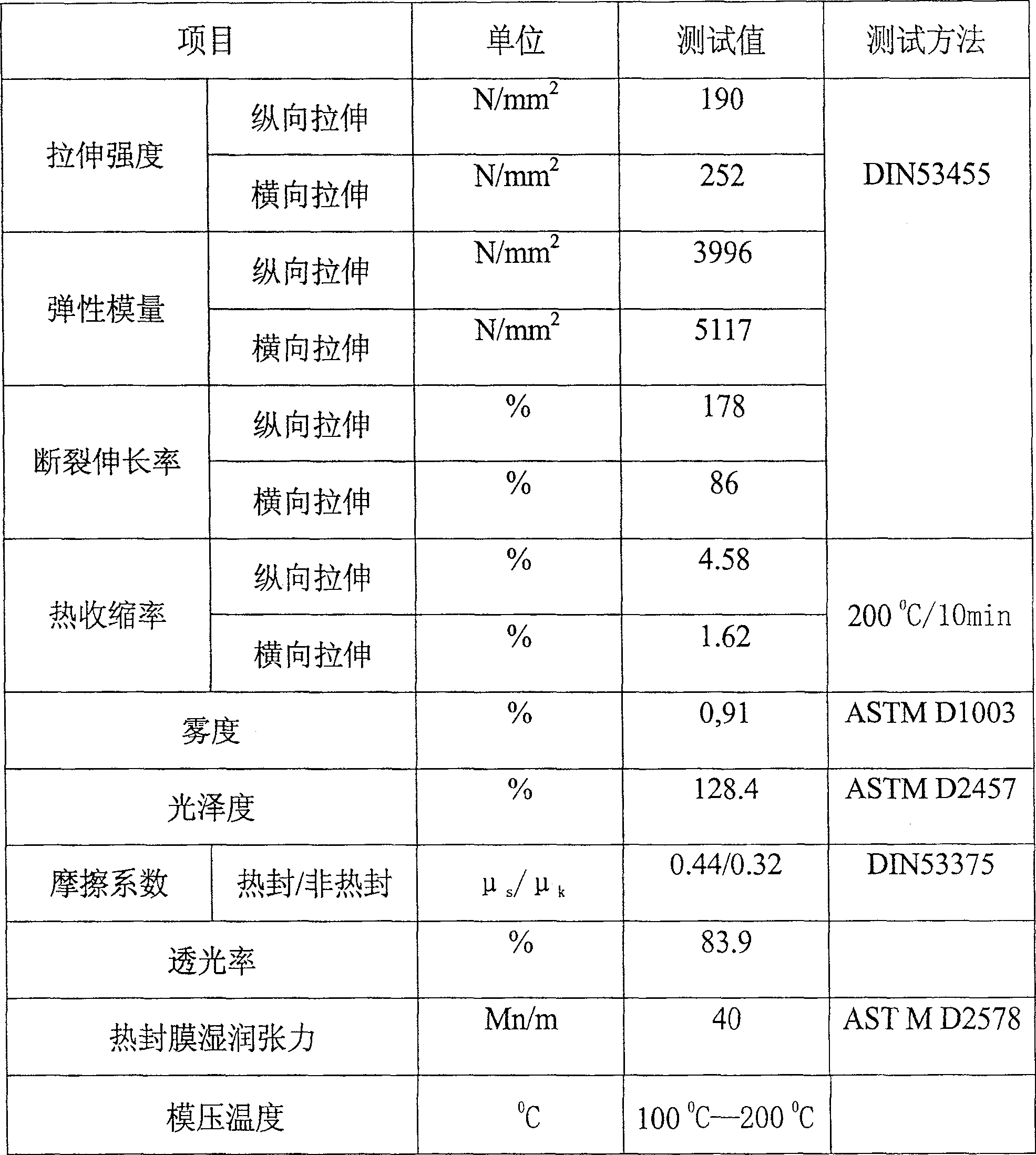

Image

Examples

example 1

[0010] Example 1: A holographic anti-counterfeiting polyester base film with a thickness of 15 μm, one of the surface layers is a holographic anti-counterfeiting surface layer, and the other surface layer is an ordinary polyester surface layer.

[0011] In this example: the thickness of the core layer is 11 μm, and selects 70% film-grade bright crystalline polyester chips and 30% polyester base film trimmings and granulated chips by weight percentage, and makes after uniform mixing; two The thickness of the surface layer is 2 μm respectively, among which the holographic anti-counterfeiting surface layer is made of 100% non-crystalline polyester chips, and the ordinary polyester surface layer is made of 70% film-grade bright crystal polyester chips and 30% additives by weight percentage The carrier chip is made after uniform mixing. The additive carrier chip contains crystalline polyester and additive silicon dioxide, wherein the content of silicon dioxide is 3000ppm by weight, ...

example 2

[0022] Example 2: A holographic anti-counterfeiting polyester base film with a thickness of 15 μm, one of the surface layers is a holographic anti-counterfeiting surface layer, and the other surface layer is also a holographic anti-counterfeiting surface layer.

[0023] In this example: the thickness of the core layer is 11 μm, select 65% film-grade bright crystalline polyester chips and 35% polyester base film trimmings and re-granulate chips by weight percentage, and make after uniform mixing; One holographic anti-counterfeiting surface layer is made of 90% non-crystalline polyester chip and 10% additive carrier chip by weight percentage, and is made after uniform mixing, and the thickness is controlled at 1.8 μm. The other holographic anti-counterfeiting surface layer is made of 80% by weight percentage Amorphous polyester chips and 20% additive carrier chips are prepared after uniform mixing, and the thickness is controlled at 2.2 μm. The additive carrier chips contain crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com