A clamping device driven by a deceleration motor

A technology of deceleration motor and clip opener, applied in the direction of electrolysis process and electrolysis components, can solve the problems affecting the service life and safety of equipment, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below according to accompanying drawing and embodiment:

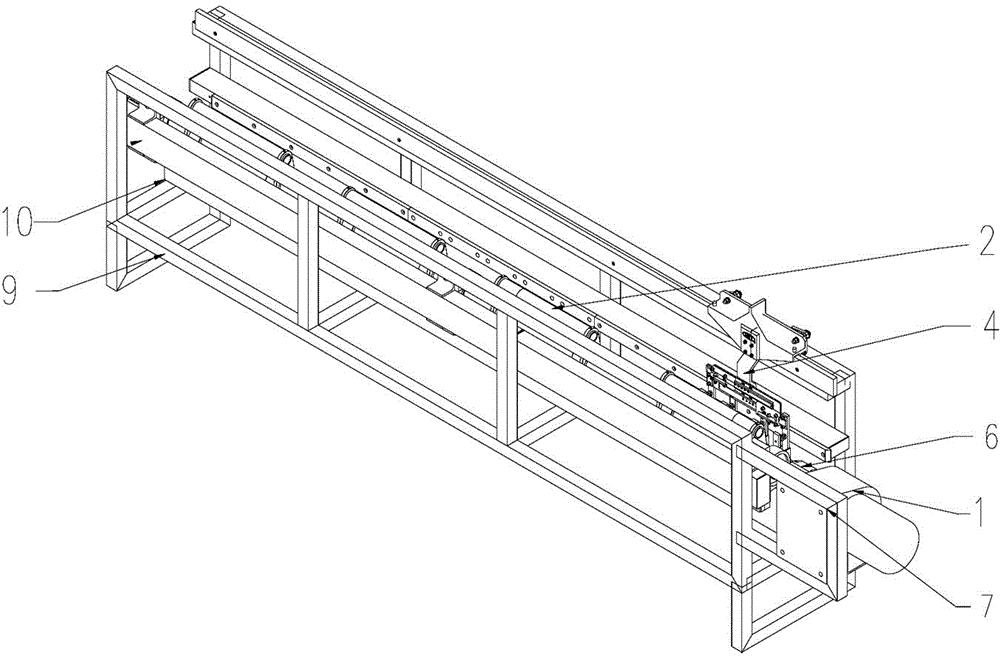

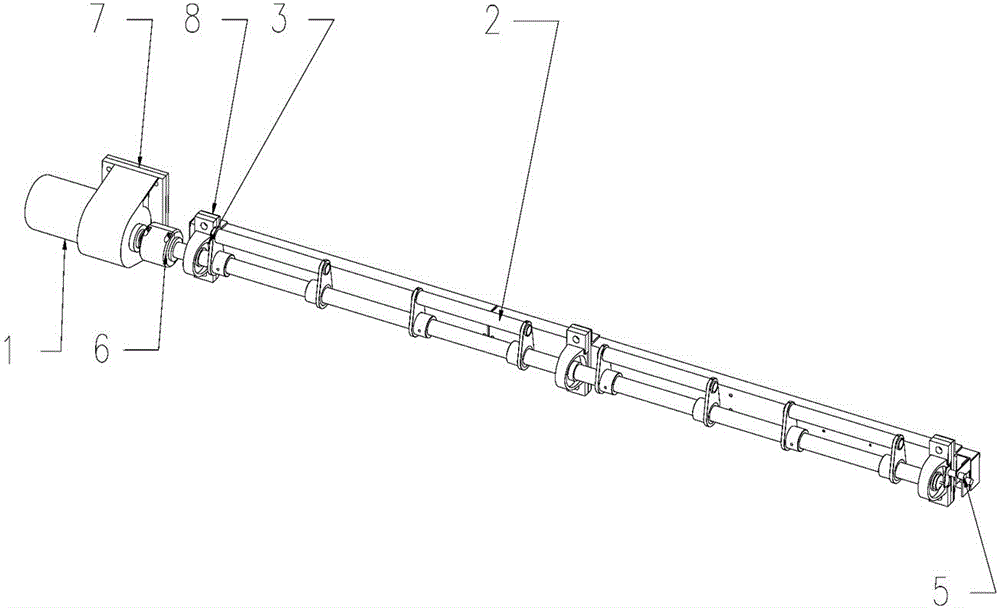

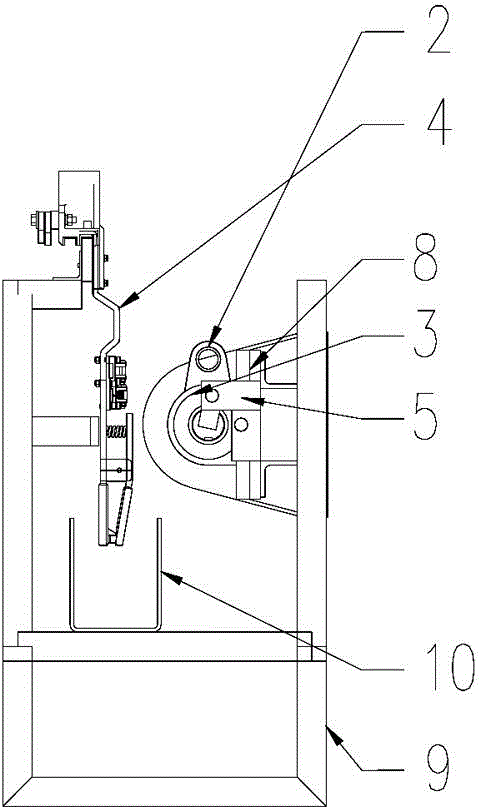

[0020] As shown in the figure, this embodiment provides a deceleration motor-driven clamp opening device, which includes a deceleration motor 1, a clamp opener 2 and a rotating shaft 3, the deceleration motor 1 drives the rotation shaft 3 to rotate, and the rotation At least one clip opener 2 that rotates with the rotating shaft 3 is fixed on the shaft 3 , and the clip opener 2 cooperates with the clamp 4 . The reduction motor 1 drives the rotation shaft 3 to rotate, and the clip opener 2 on the rotation shaft 3 swings with the rotation shaft 3. After swinging to contact with the clamp 4, the splint of the clamp 4 is pressed down due to the action of the reduction motor 1, and the clamp 4 is opened. .

[0021] It also includes an inductor 5 , which senses the opening and closing position of the clamp 6 , and when sensing that the clamp 6 is fully opened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com