Liquid crystal display and backlight module thereof

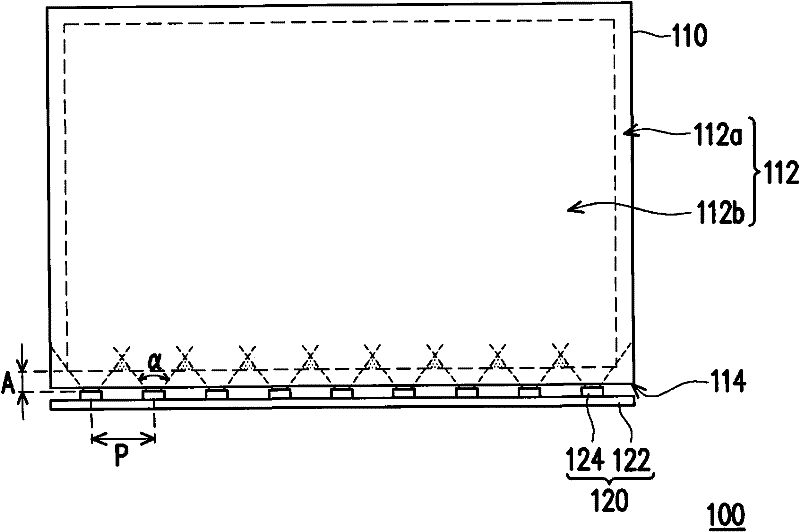

A liquid crystal display and backlight module technology, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of cost increase and achieve the effect of improving light spots and increasing light distribution intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

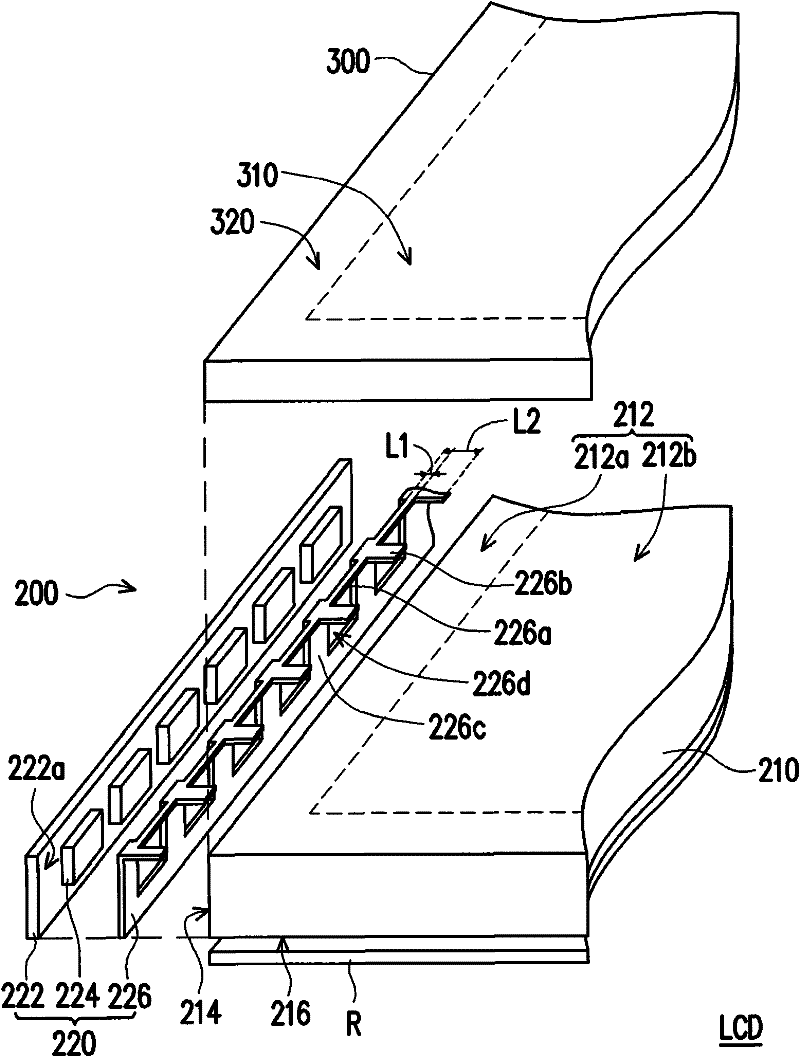

[0065] figure 2 is a schematic diagram of the liquid crystal display of the first embodiment of the present invention, and image 3 It is a schematic top view of the backlight module according to the first embodiment of the present invention. Please refer to figure 2 , the liquid crystal display LCD of this embodiment includes a backlight module 200 and a liquid crystal display panel 300 , wherein the liquid crystal display panel 300 is disposed above the backlight module 200 . In this embodiment, the liquid crystal display panel 300 is, for example, a transmissive LCD panel or a transflective LCD panel.

[0066] Such as figure 2 and image 3 As shown, the backlight module 200 includes a light guide plate 210 and a linear light source 220 . The light guide plate 210 has a top light exit surface 212 and a side light incident surface 214 connected to the top light exit surface 212, and the top light exit surface 212 includes a peripheral area 212a connected to the side l...

no. 2 example

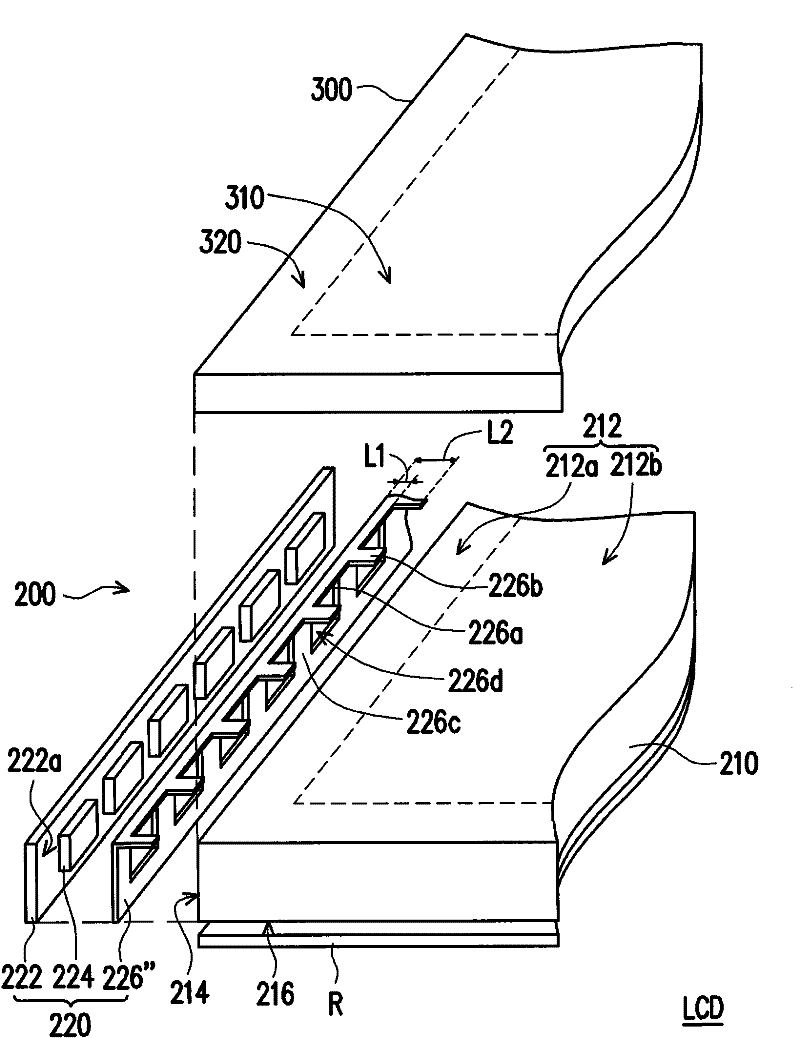

[0076] Figure 4 It is a schematic diagram of a liquid crystal display according to a second embodiment of the present invention. Please refer to Figure 4 , the liquid crystal display LCD' of the present embodiment is similar to the liquid crystal display LCD of the first embodiment, but the main difference between the two is that: the reflector 226' of the present embodiment includes a first reflective portion 226a, a second reflective portion 226b and an assembly part 226c' connected to the linear light source 220, the assembly part 226c' is connected to the first reflection part 226a and the second reflection part 226b, and the assembly part 226c' includes a plurality of strip structures S, and each solid state light emitting element 224 are respectively located between two adjacent strip structures S. For example, the aforementioned assembly part 226c' is fixed on the circuit board 222 by glue or other methods.

[0077] Figure 4' It is a schematic diagram of another ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com