Press-contact pogo pin connector

一种压接型、连接器的技术,应用在连接、连接装置的零部件、耦合装置等方向,能够解决不能充分满足低背性等问题,达到实现小型化、简单结构、容易多极化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Next, embodiments of the present invention will be described based on examples shown in the drawings.

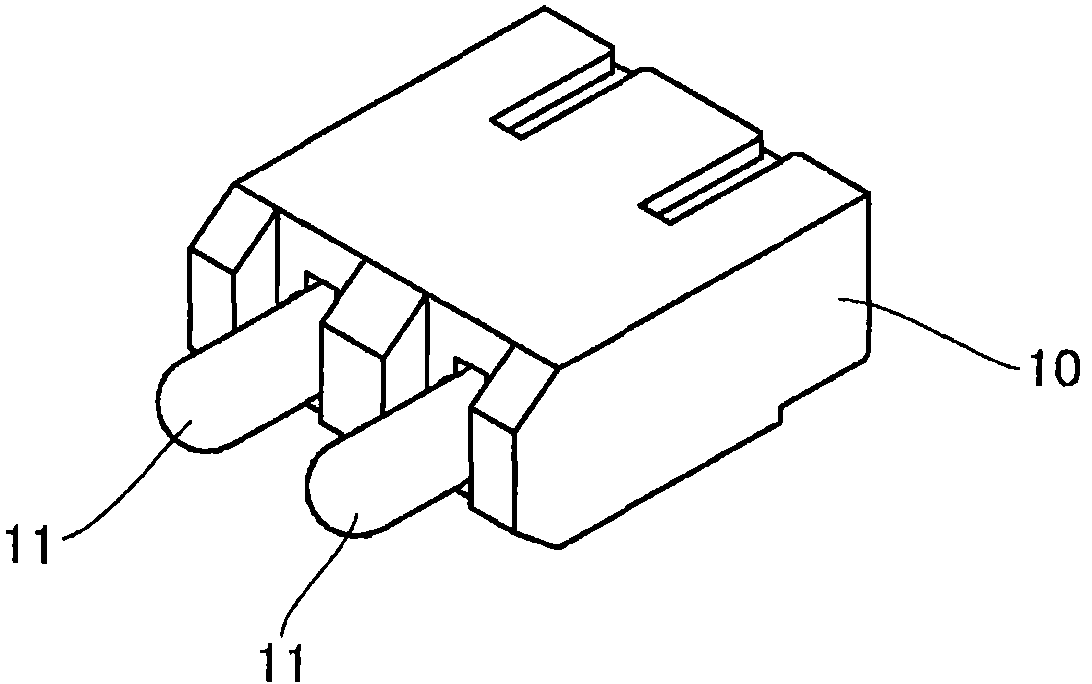

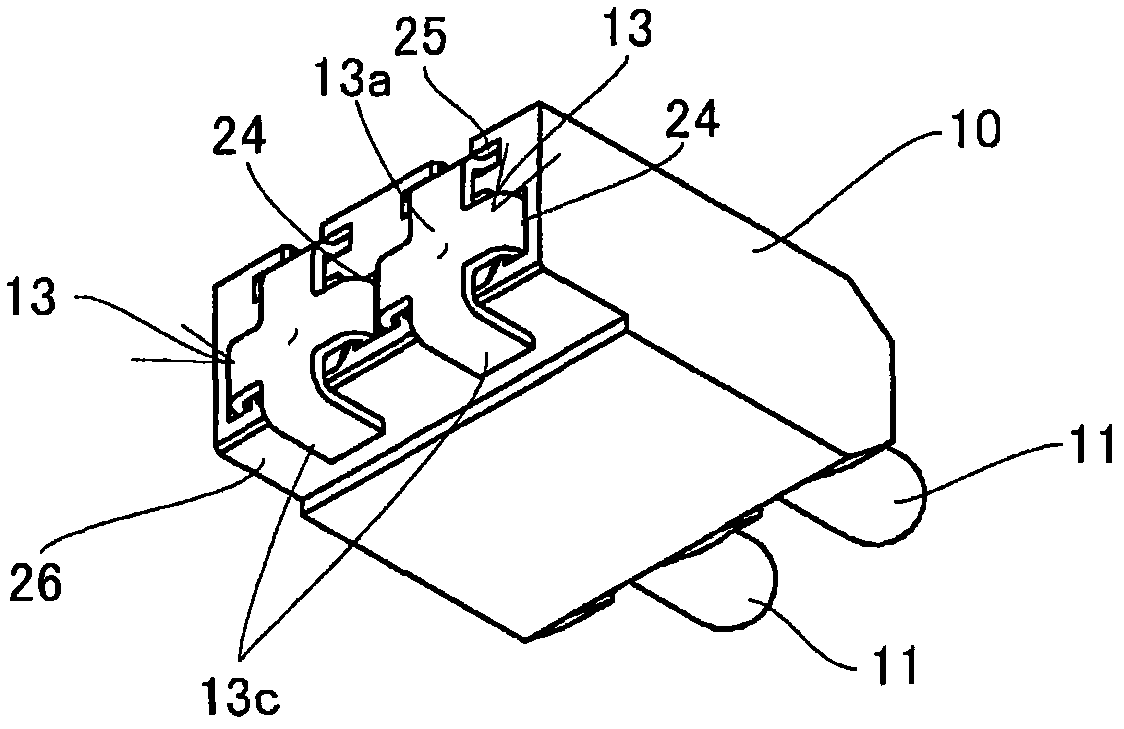

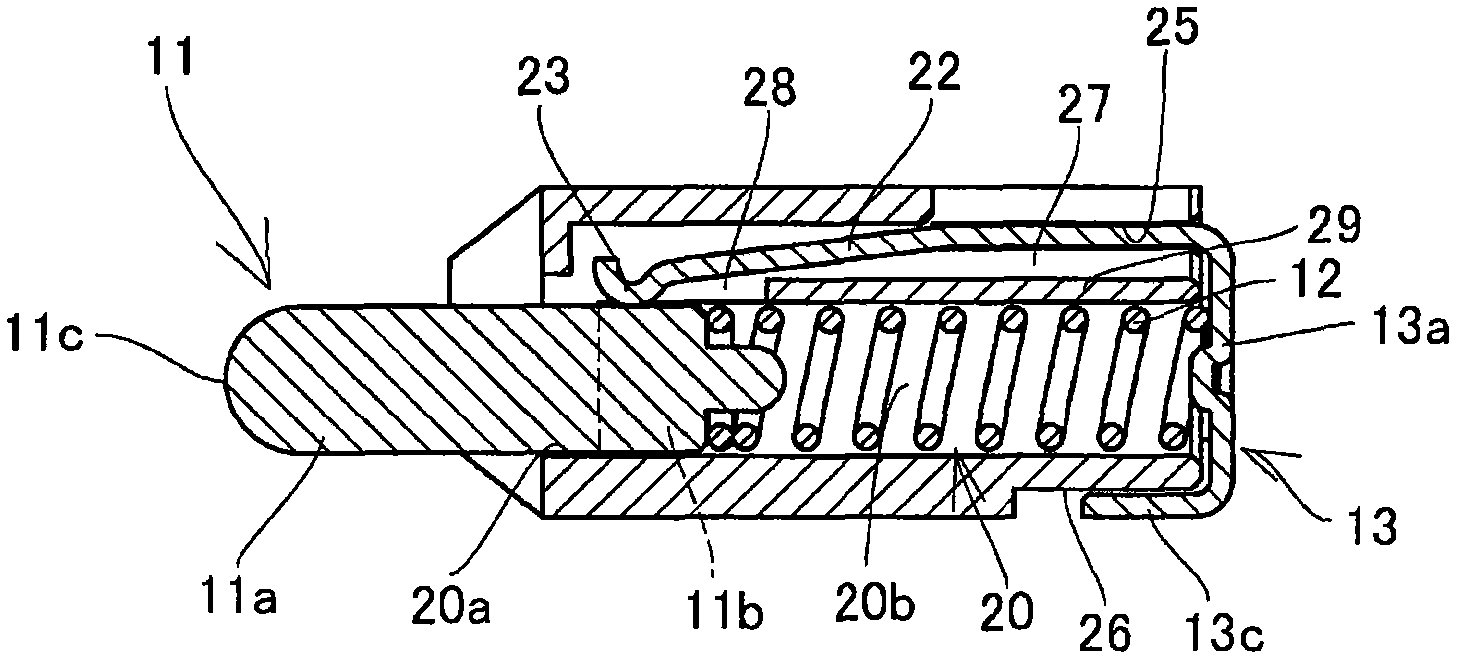

[0070] Figure 1 to Figure 7 This is the first embodiment of the ejector crimp connector of the present invention, showing an example used for a battery connector in which a plurality of ejector pins protrude elastically. The thimble crimp connector is composed of a housing 10 , a thimble 11 , a coil spring 12 and a contact 13 . A pair of thimbles 11 , 11 that can be freely entered and exited are assembled in the housing 10 .

[0071] The casing 10 is obtained by injection molding an insulating synthetic resin material, and is formed with a cylindrical hole 20 opening through the front and rear surfaces. The cylindrical hole 20 has a circular shape at the front opening 20a of the cylindrical hole on the front end of the casing, but the opening 20a on the front casing side of the cylindrical hole is closer to the contact point than the opening 20a on the front casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com