Medium conveyer

A medium conveying and medium technology, which is applied in the field of medium conveying devices, can solve the problems of inability to discharge medium, inability to convey, and poor detection accuracy of medium length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

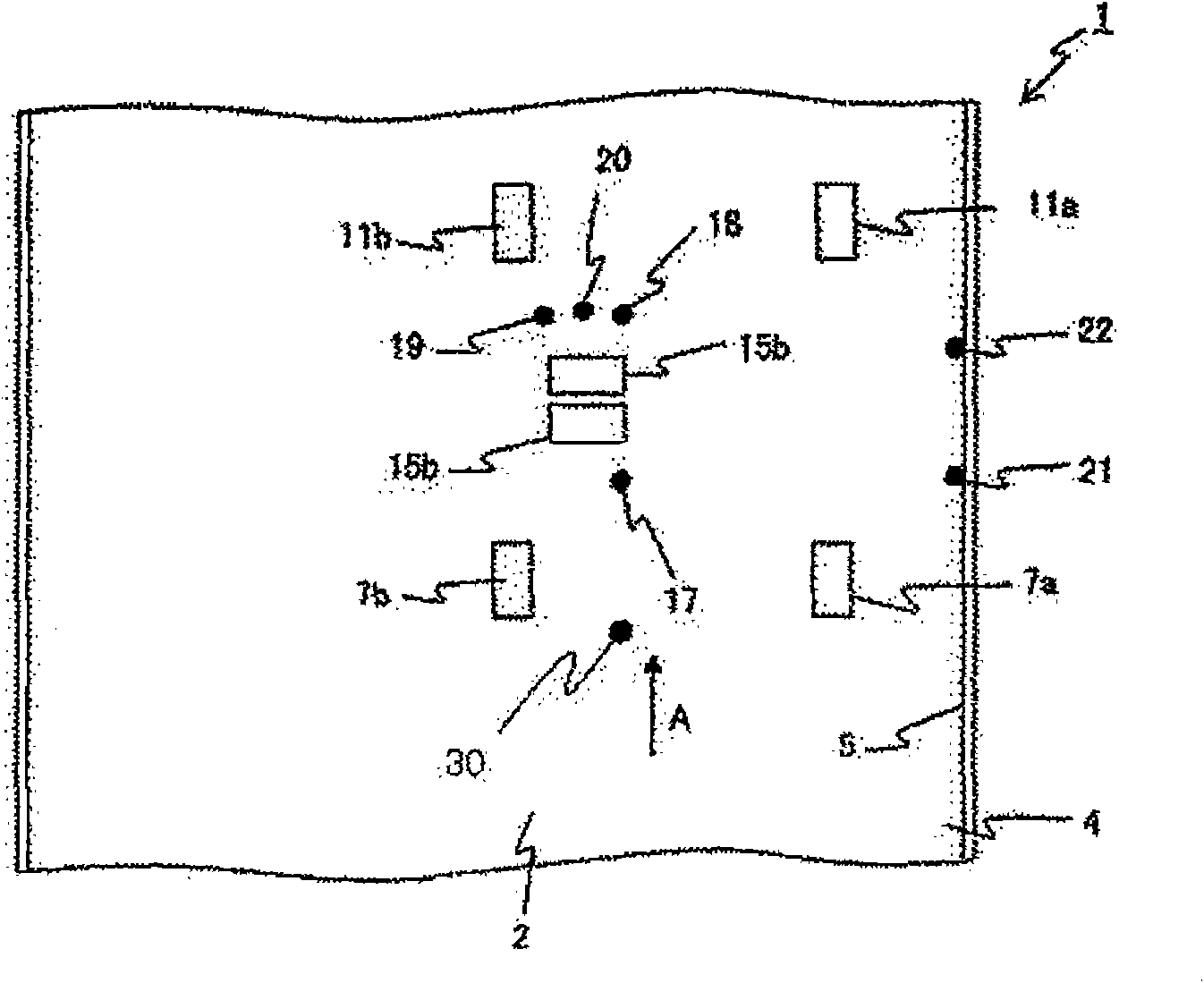

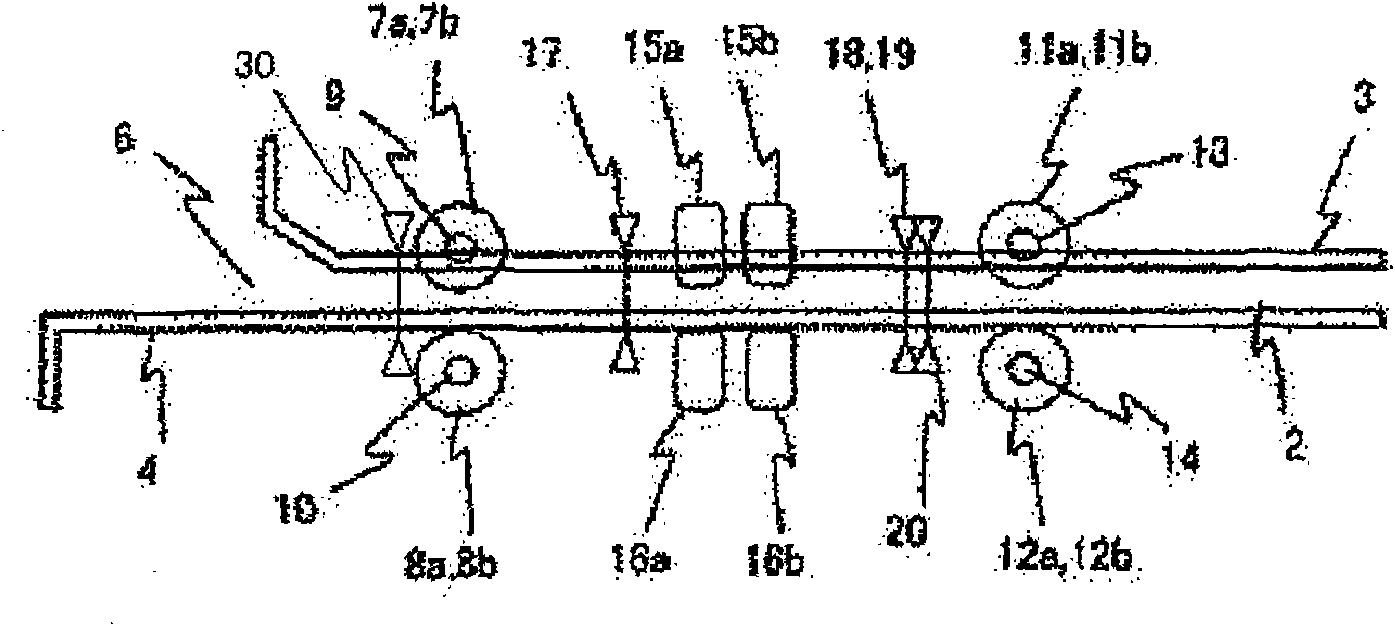

[0024] in figure 1 , figure 2 In the medium transport device 1 of the embodiment, the transport path 2 is provided, and the transport path 2 is formed by arranging the upper guide plate 3 and the lower guide plate 4 at intervals. On one side of the lower guide plate 4, a reference surface 5 serving as a reference for medium conveyance is formed. Conveyor Path 2 figure 2 The left side of the middle is the media insertion port 6. The insertion port 6 also doubles as a medium discharge port. Media of different sizes are conveyed in the conveying path 2, but the width of the conveying path 2 is formed to be wide so that all the media can be conveyed.

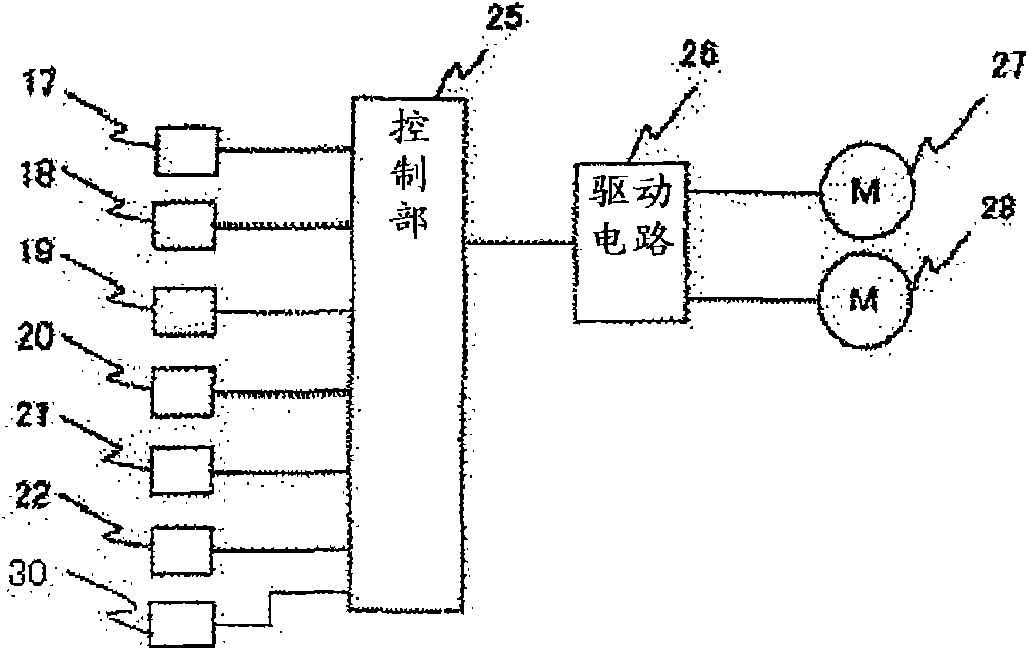

[0025] Feed rollers 7a and 7b are rotatably arranged on the conveying path 2. The feed rollers 7a and 7b are rollers that convey the medium in the direction of arrow A, and are rotationally driven by a motor described later. The pressing rollers 8a and 8b can be press-contacted to the feed rollers 7a and 7b, respectively. The fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com