Long-stalked crop harvester

A technology for high-stalk crops and harvesters, which is applied in the direction of harvesters, agricultural machinery and implements, and applications, and can solve problems such as difficult harvesting of high-stalk crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

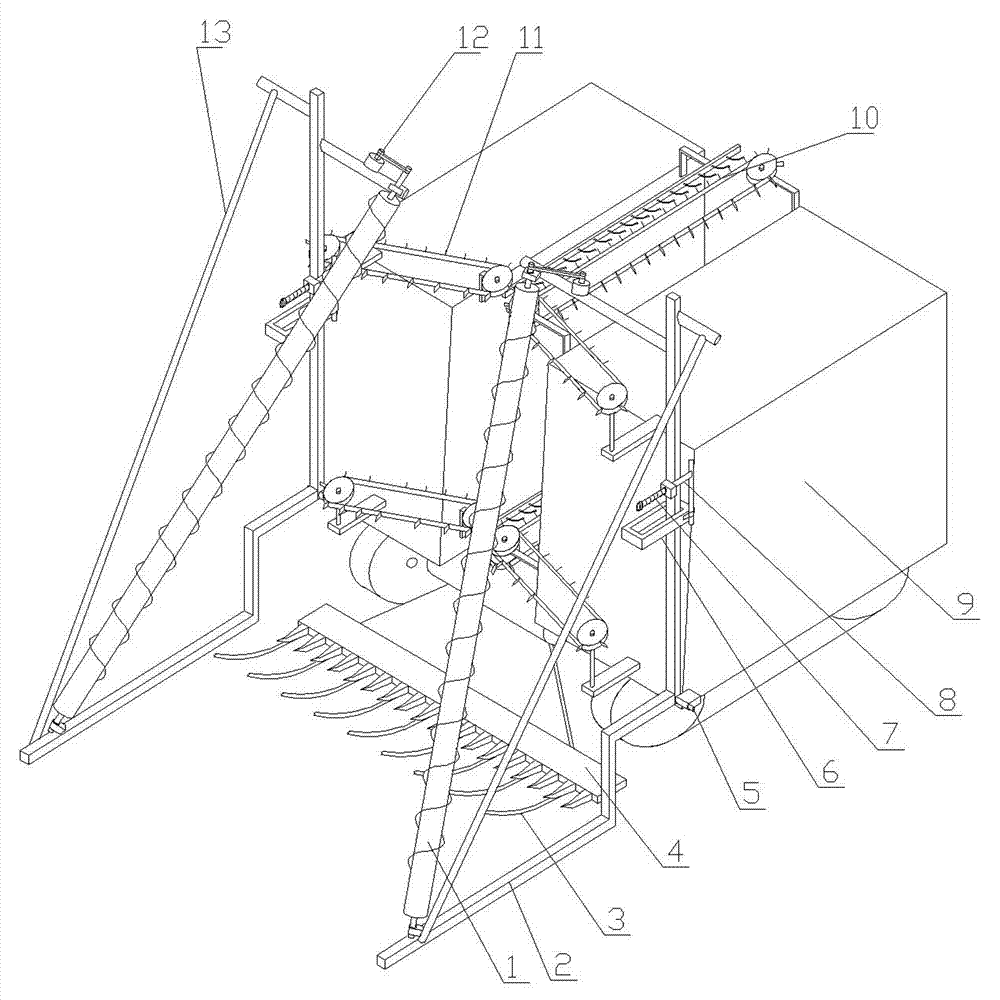

[0015] like figure 1 A kind of specific embodiment shown, it comprises crop clamping and lifting conveying device 10, crop gathering device 11, cutter 4 and motor vehicle body 9, the middle part of motor vehicle body 9 is provided with a crop channel, and crop clamps and lifts The conveying device 10 is arranged on the top of the crop passage, the crop gathering device 11 is arranged on the top of the front end of the crop passage, the cutter 4 is arranged on the front of the bottom of the motor vehicle body 9, and the left and right sides of the front end of the motor vehicle body 9 are respectively provided with a stirrer. The auger support 2, the rear side of the bottom of the auger support 2 is connected with the motor vehicle body 9 through the rotating shaft 5, so that the auger support 2 can rotate around the rotating shaft 5 back and forth, and the auger support 2 and the motor vehicle body 9 are connected with the auger support Turn the angle stopper.

[0016] The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com