Screw remover

A technology of screw and driving end, which is applied in the field of screw remover, which can solve the problems of screw workpiece damage, damage, and difficulty in turning the hexagonal wrench, etc., and achieve the effect of pulling the screw really

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

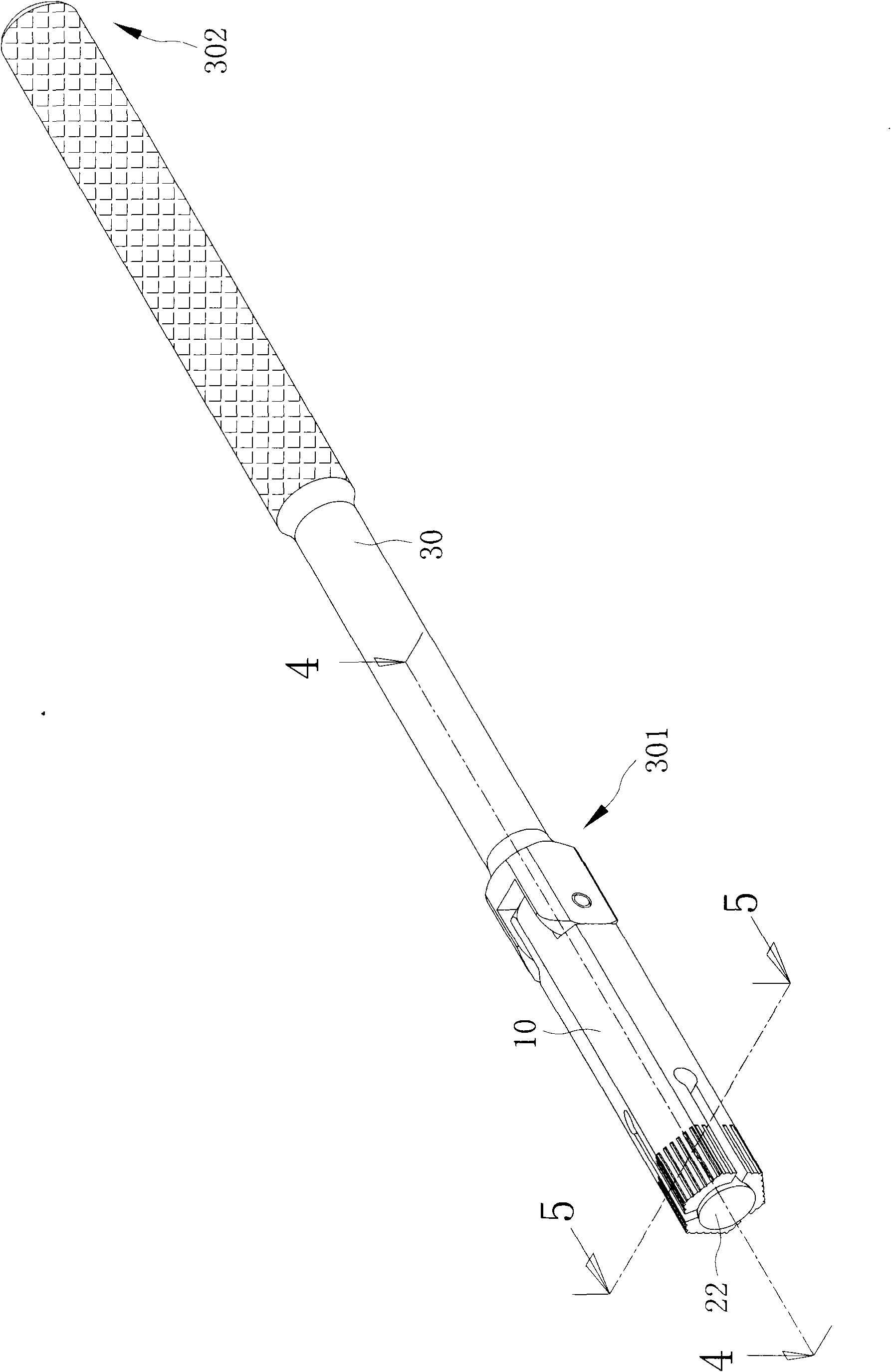

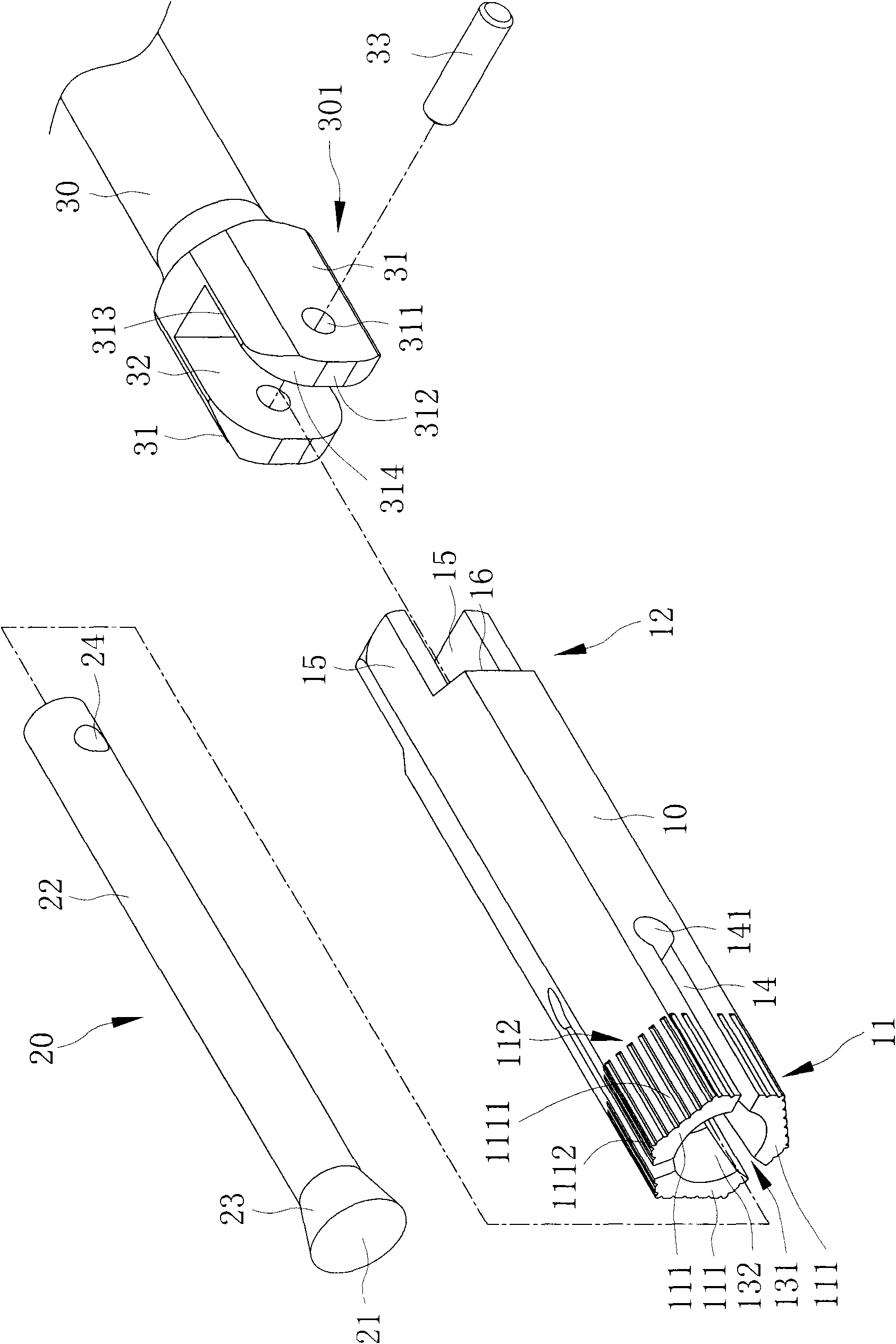

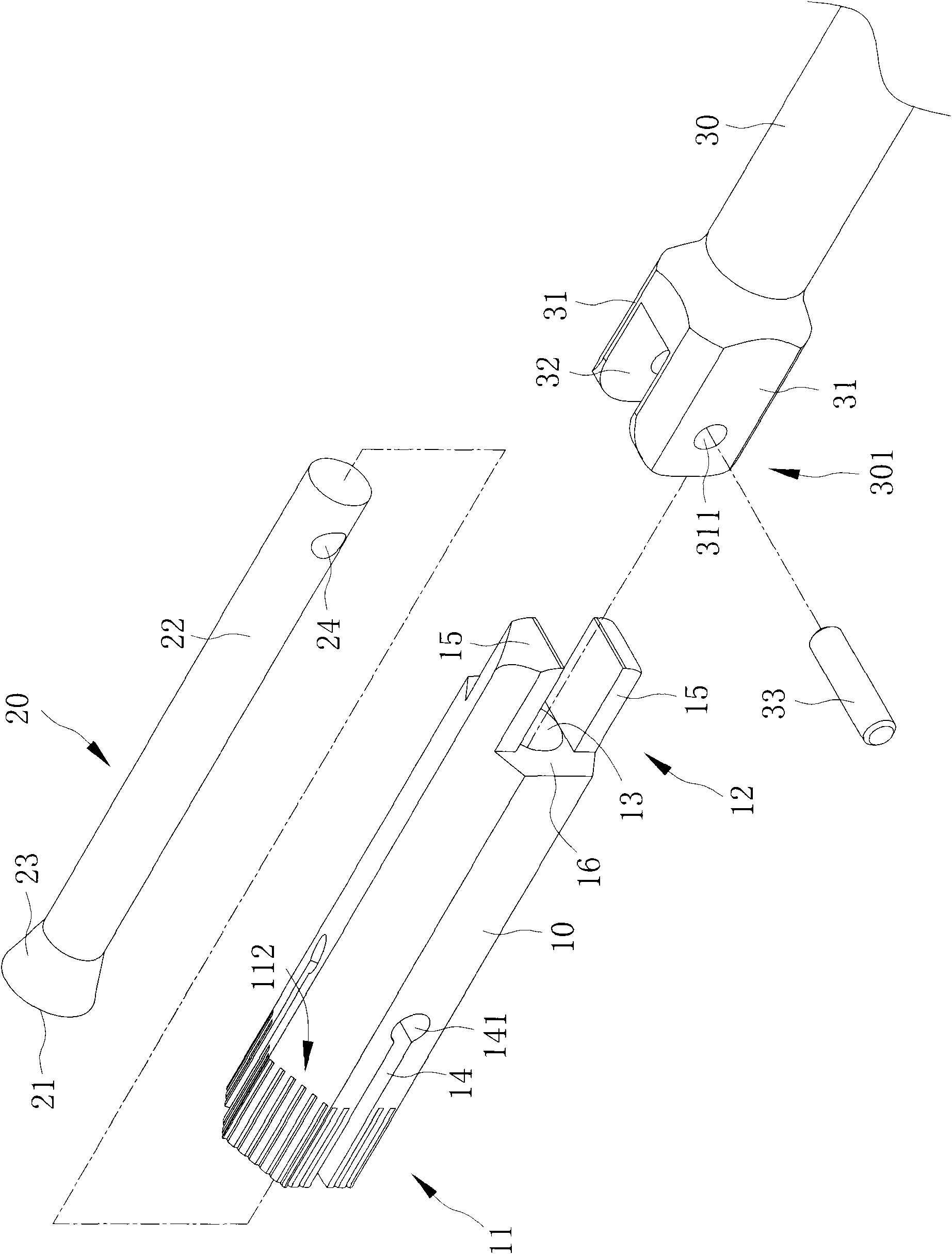

[0049] refer to Figure 1 to Figure 3 , is a three-dimensional appearance view and a three-dimensional exploded view of the screw remover of the present invention. The present invention includes a body 10, a pressing member 20 and a control member 30, the pressing member 20 is passed through the body 10, the control member 30 is connected to the pressing member 20, The displacement of the pressing member 20 relative to the main body 10 is controlled so that the pressing member 20 presses the main body 10 to expand.

[0050] Also refer to Figure 4 as well as Figure 5 , the body 10 has a driving end 11 and a connecting end 12, the driving end 11 is integrally connected with the connecting end 12, the driving end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com