Ratchet wrench

A technology of ratchet wrench and ratchet parts, which is applied in the field of wrenches, which can solve problems such as reduced service life, obstruction of steel ball movement, and loss of function of ratchet wrench, so as to achieve the effects of improving service life, simplifying processing procedures, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

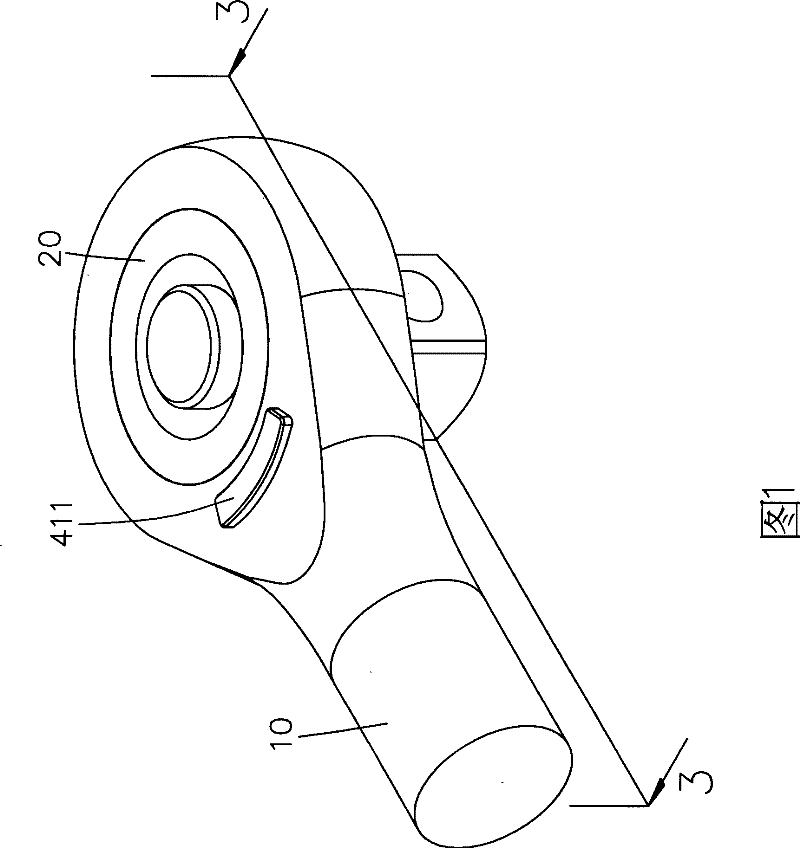

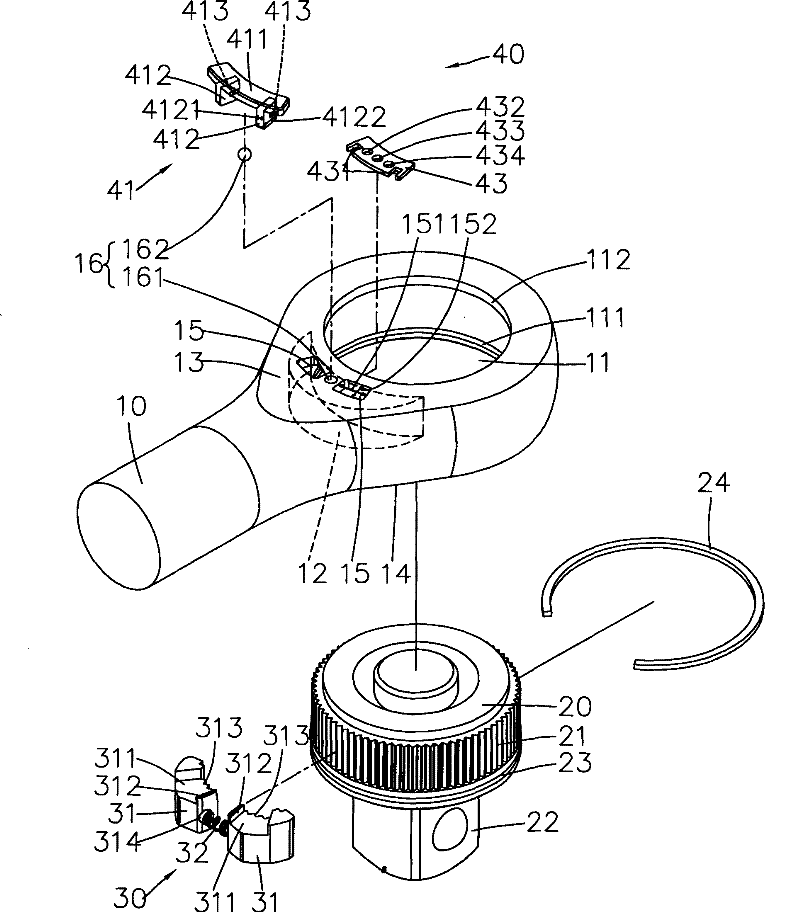

[0033] refer to figure 1 and figure 2 , is a three-dimensional appearance view and a three-dimensional exploded view of the ratchet wrench of the present invention. The ratchet wrench of the present invention includes a body 10 , a ratchet component 20 , a locking device 30 and a reversing switch 40 .

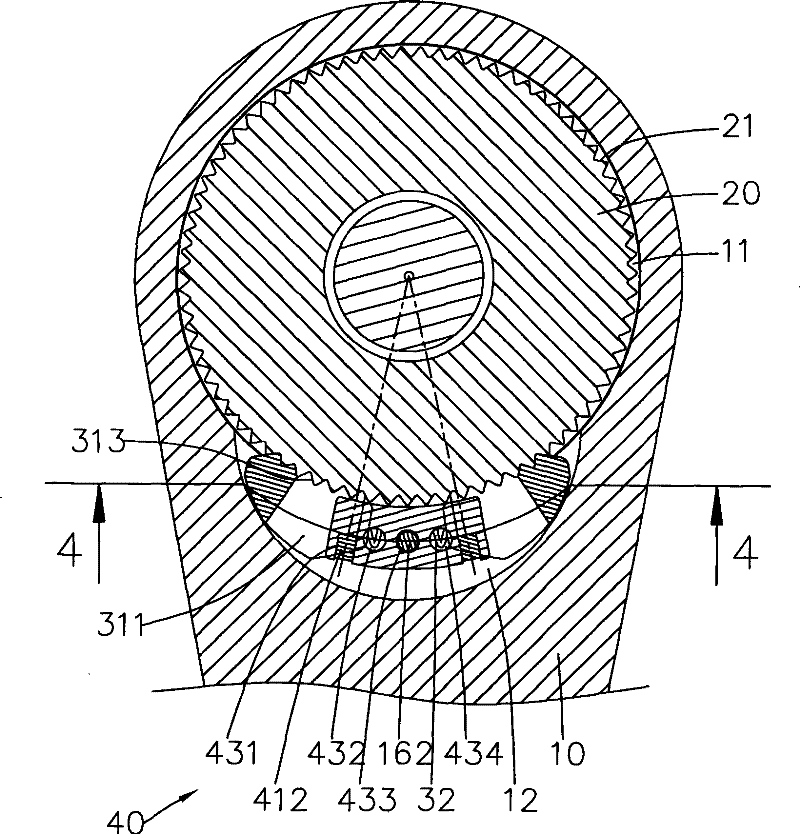

[0034] The body 10 is provided with a circular first accommodating space 11, and the inner wall of the first accommodating space 11 is provided with an arc-shaped second accommodating space 12, the second accommodating space 12 communicates with the first accommodating space 11 . The body 10 has opposite first side 13 and second side 14, the first accommodating space 11 penetrates the two sides 13, 14 of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com