Device and method for transversely tensioning prestress of trapezoid sleeper

A transverse tensioning and prestressing technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of no sleeper applying such transverse prestressing, no tooling equipment, etc., and achieve convenient and fast transverse tensioning construction, low cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

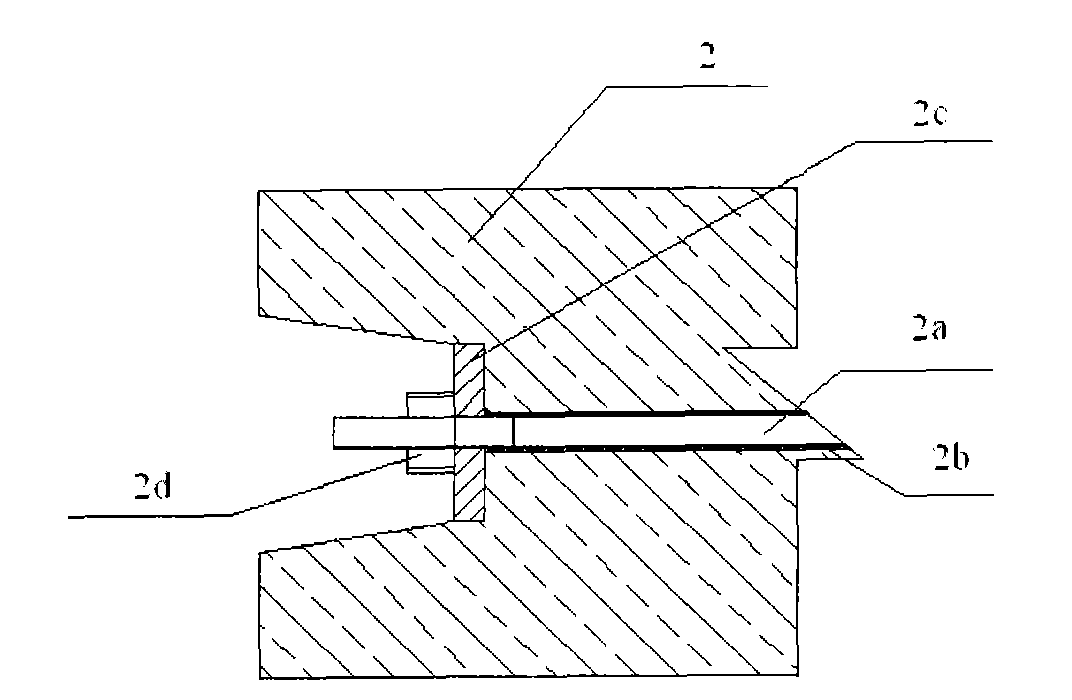

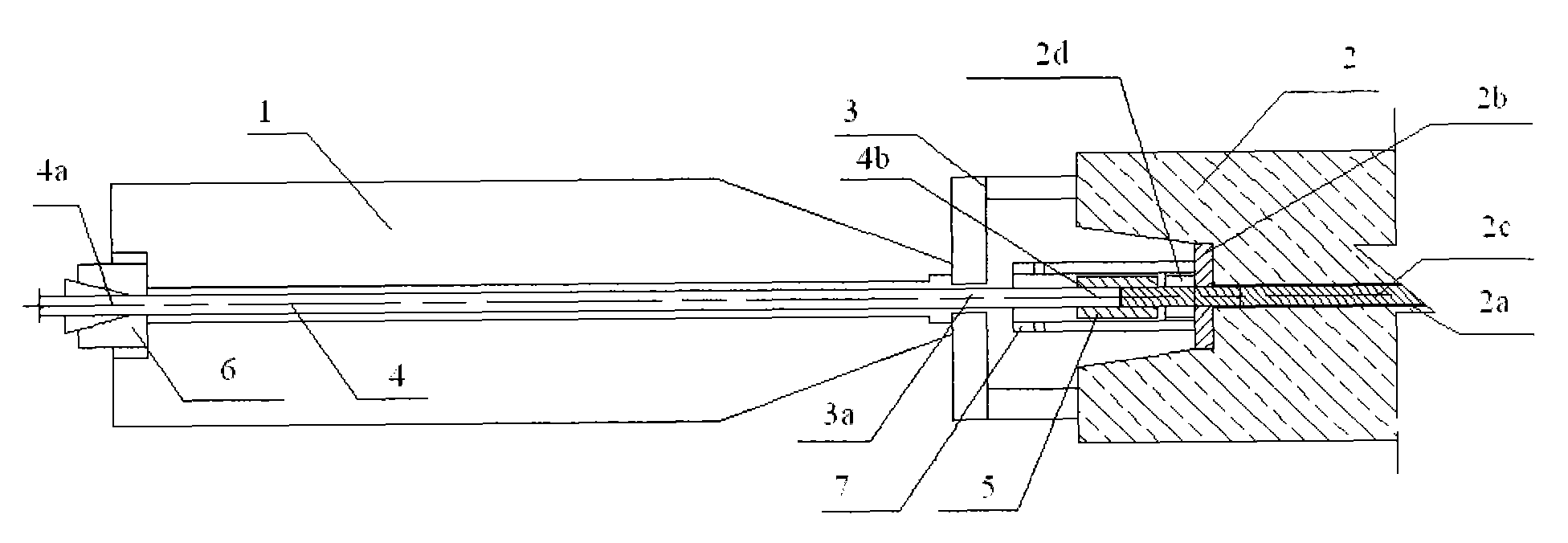

[0023] The following combination figure 1 To describe a specific use occasion of an embodiment of the prestressed transverse tensioning device according to the present invention, in figure 1 shows the structure of the tensioned anchor hole of the trapezoidal sleeper 2, the major diameter of the anchor hole is 80mm, the minor diameter is 60mm, and the depth is 65mm, and the anchor nut 2d is installed in the anchor hole protruding from the PC steel On the rod 2a, the PC steel rod protrudes about 30mm, and is 35mm away from the concrete outer side of the trapezoidal sleeper. Each trapezoidal sleeper has 4 PC steel rods 2a. The PC steel rods 2a are high-strength round steel with a diameter of 10mm and a tensile strength of 124KN. 65 threads, wherein the steel rod 2a is covered with a plastic sleeve 2c with an inner diameter of 11mm, so as to be isolated from the concrete. In addition, a support plate 2b is provided at the bottom of the anchor hole to prevent local stress concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com