On-site wind pressure resistance equivalent static-load detection method and device

A static load detection and wind pressure resistance technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, and testing of machinery/structural components, etc. The detection method is simple and quick, the operation is convenient, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

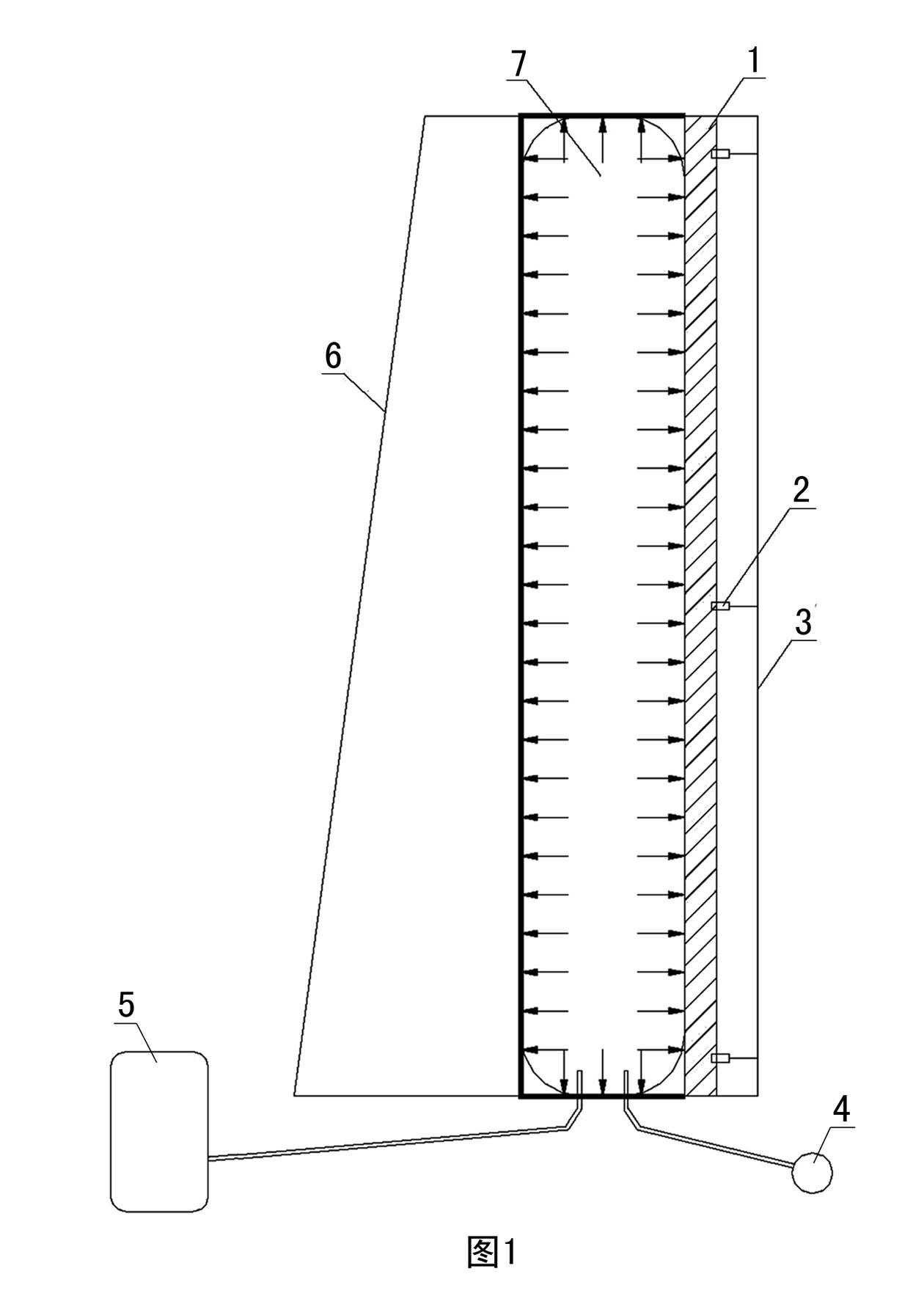

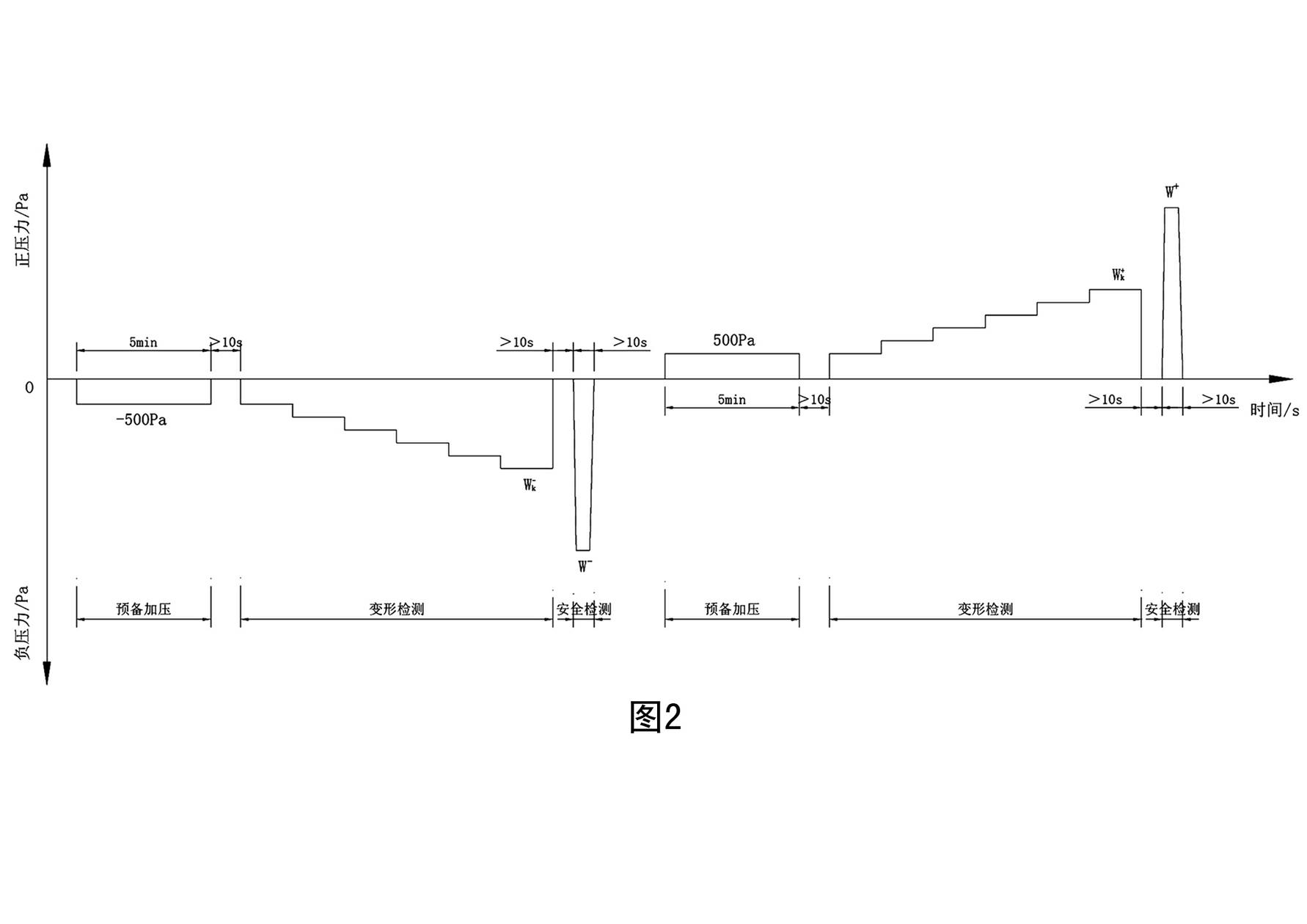

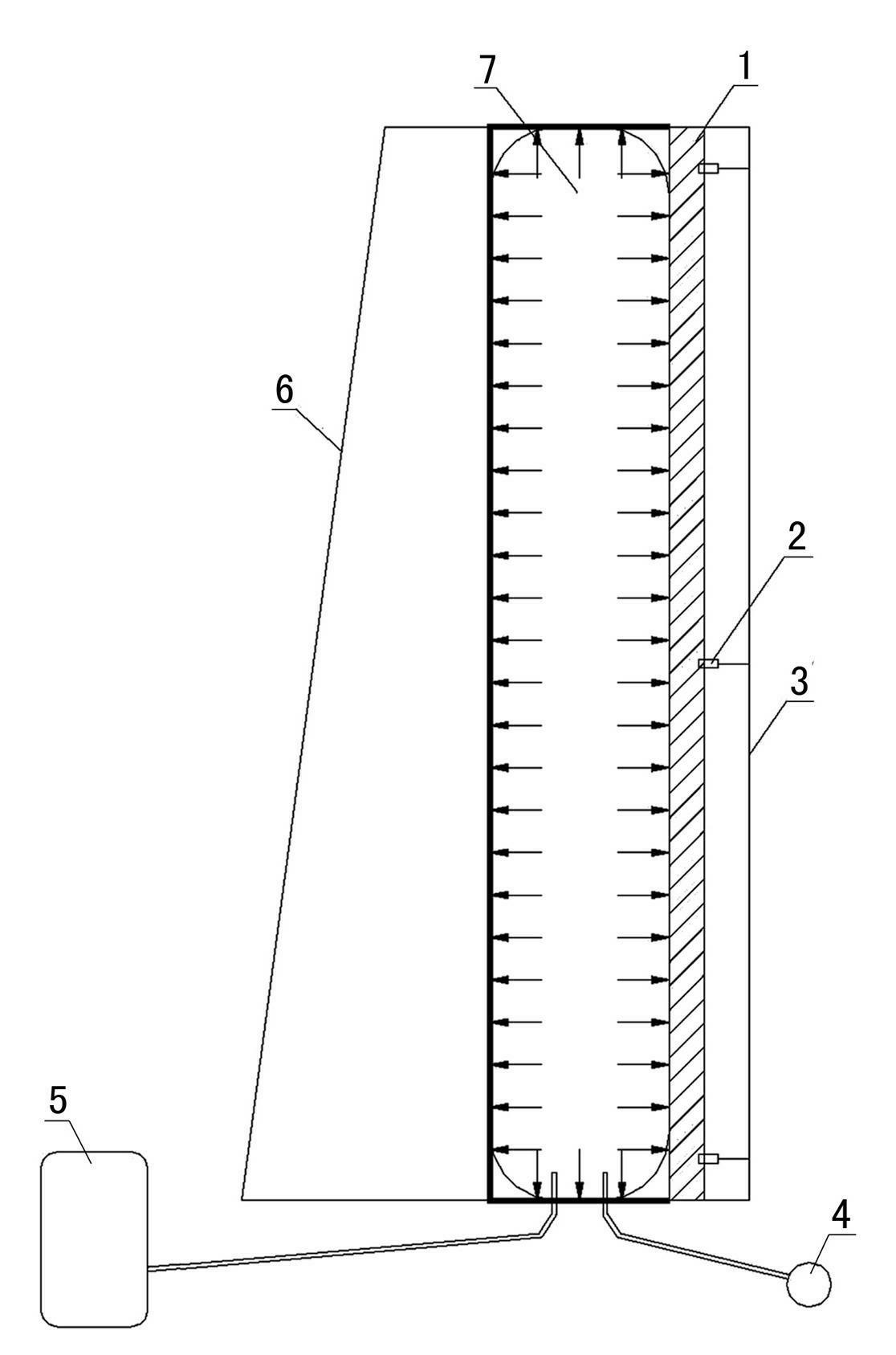

[0023] Examples see figure 1 , figure 2 As shown, this on-site wind pressure resistance performance equivalent static load testing method (airbag method), its steps are: Step 1, switch the openable part on the tested curtain wall component 1 for no less than five times, and finally close it tightly; Step 2. Fixedly install a fixed frame 3 on one side of the measured curtain wall component 1, and fixedly connect the displacement meter 2 matched with the measured curtain wall component on the fixed frame 3. The position of the displacement meter is consistent with the measuring point on the measured curtain wall component Correspondingly, and the accuracy of the displacement meter reaches 25% of the full scale; Step 3, fixedly install the reaction force support frame 6 on the other side of the measured curtain wall component 1, and the reaction force support frame 6 and the measured curtain wall component 1 There is a gap between them; step 4, place the air bag 7 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com