Device for testing influence of multiphase flow on tensile strength of rock

A technology of tensile strength and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to evaluate the influence of multiphase flow on rock tensile strength, and inability to measure liquid breakthrough pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below according to accompanying drawing:

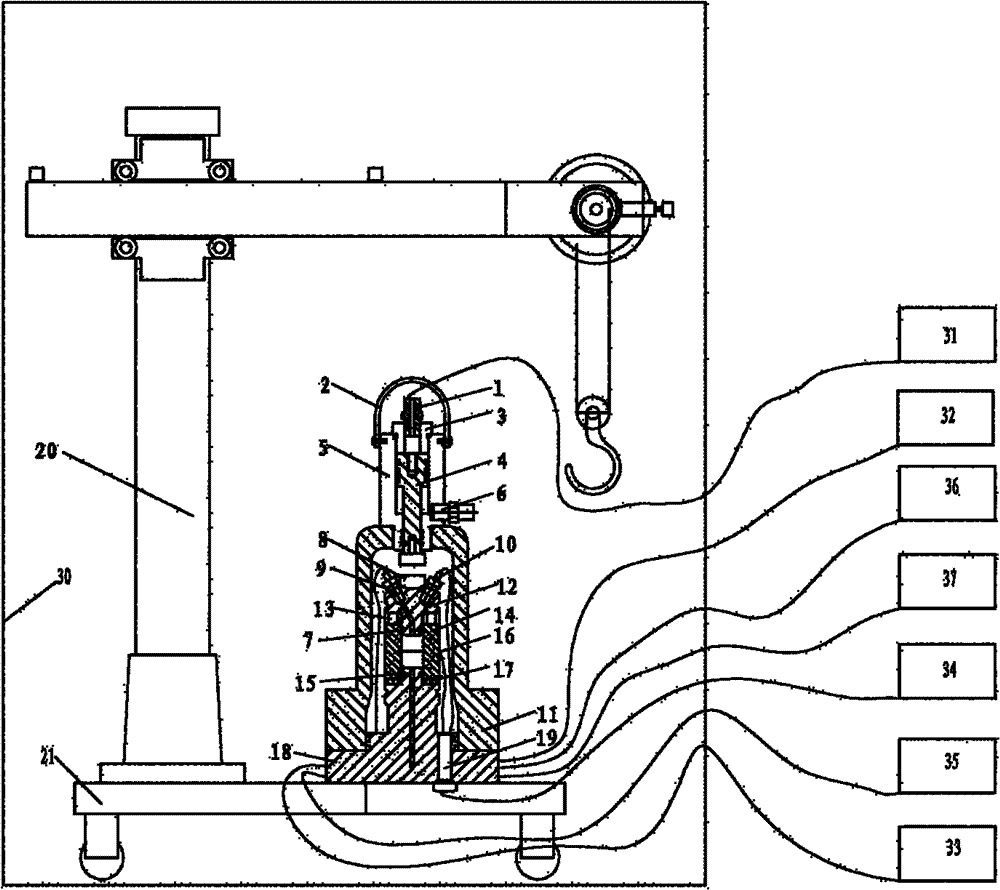

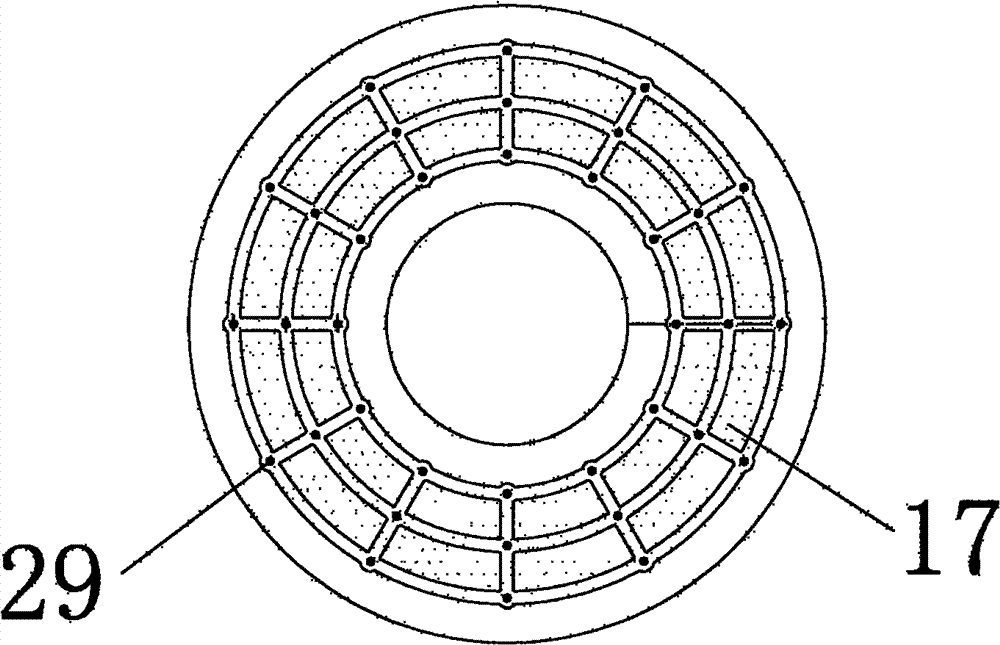

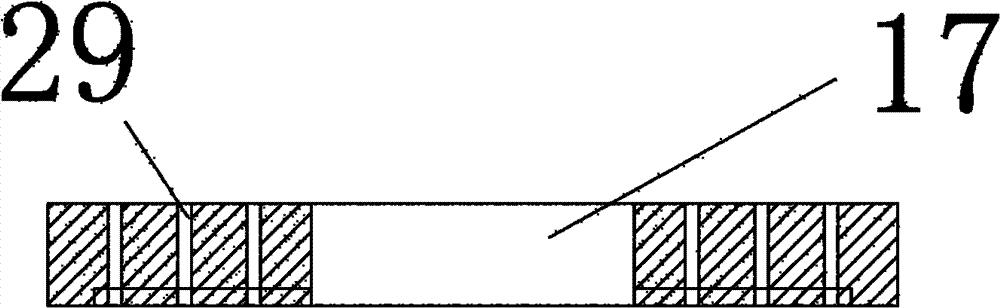

[0028] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that a model test device for the influence of multiphase flow on the tensile strength of rock consists of a pressurized joint 1, a lifting ring 2, a cylinder head 3, a reciprocating piston 4, a cylinder body 5, a back pressure joint 6, a sealing ring 7, and a balance weight 8. Internal pressure unloading adapter 9, pore water pressure loading adapter 10, bell jar 11, upper platen 12, ring-shaped embedded clay plate pad 13, hollow cylindrical sample 14, sealing ring 15, BQ120-10BA Type resistance strain gauge 16, annular porous plate 17, base 18, lead screw 19, GCT type manual hoist 20, YP-150 type disc trolley 21, confining pressure loading screw hole 22, internal pressure loading screw hole 23, pore water Pressure loading screw hole 24, pore air pressure loading screw hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com