Throwing mechanism for dried diet feeder

A feeding machine and throwing machine technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems that cannot fully meet the requirements of farmers, uneven distribution of feed, small fans, etc., to prevent water soaking and moisture, Uniform distribution and beautiful fan-shaped area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

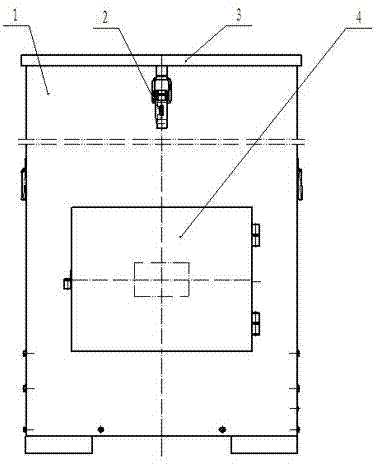

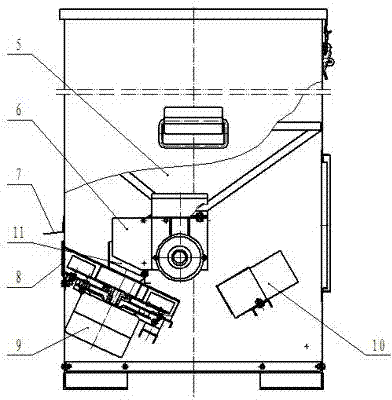

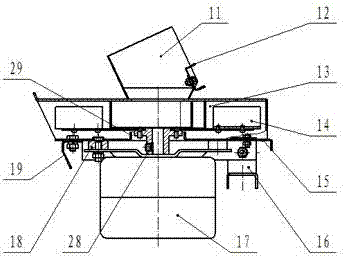

[0025] Such as Figure 1-10 As shown, the feeding machine includes a box body 1, a box cover 3, a translational feeder 6, a throwing machine 9, a controller 10 and a hopper 11, and the box cover 3 is installed on the box body 1 with a door 4 , the cone bucket 5 is installed in the box body 1, and the translation type blanking machine 6 is connected to the cone bucket 5 through the mounting frame. A hopper 11 is installed between the translational blanking machine 6, and the controller 10 in the box body 1 is connected to the translational blanking machine 6 and the throwing machine 9; the throwing machine 9 is covered by a throwing tray cover 13 , Throwing tray 14, base plate 15, mounting frame 16, material throwing motor 17 and mounting plate 19 are formed, the mounting frame 16 and mounting plate 19 are installed on the base plate 15 through bolts, spring washers, nuts, and the base plate 15 is installed through the mounting frame 16 and The plate 19 is installed in the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com