Vehicle body draft, bolster and buffer assembling and welding process

A technology for bolstering and assembling welding, which is applied to the machining of raw materials for bolstering of car body, aluminum alloy assembling welding product process, and assembling welding technology field, which can solve the problems of waste, inconvenient operation, easy generation of pores, etc., and reduce production. Cost and energy waste, guarantee of changes in material volume and size, and the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

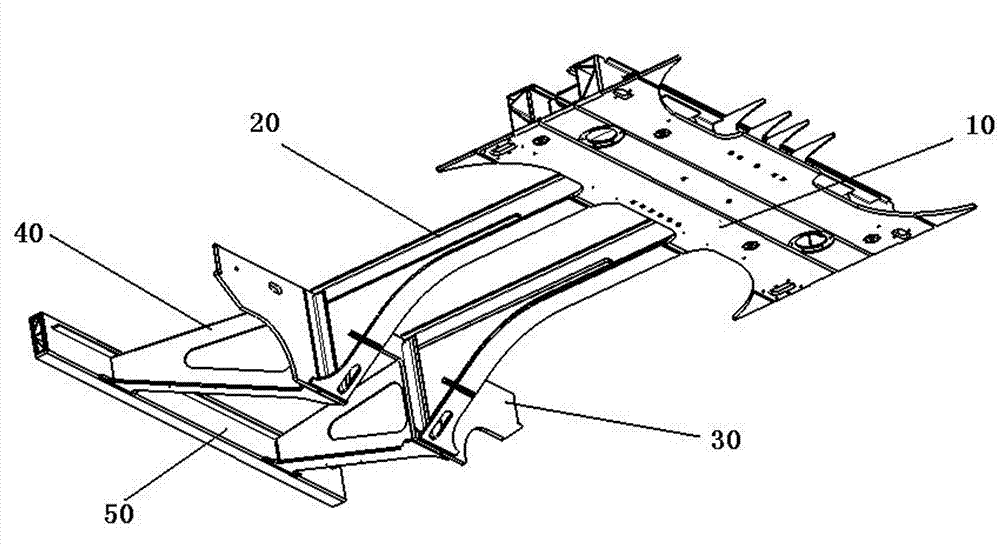

[0031] see figure 1 , the present invention provides an assembly welding process of the MP end car body lead pillow of aluminum weldment, the MP end lead pillow is composed of five parts: a bolster 10, a draw beam 20, a coupler mounting seat 30, a buffer beam 40, and an end beam 50 In the traction pillow 20 at the MP end, the upper plane of the corbel 10 is connected to the floor, and the lower plane is assembled with the bogie. The mounting hole on the coupler mounting seat 30 is assembled with the coupler, and the side is welded with the buffer beam 40, and the buffer beam 40 plays a role of buffering during the operation of the vehicle.

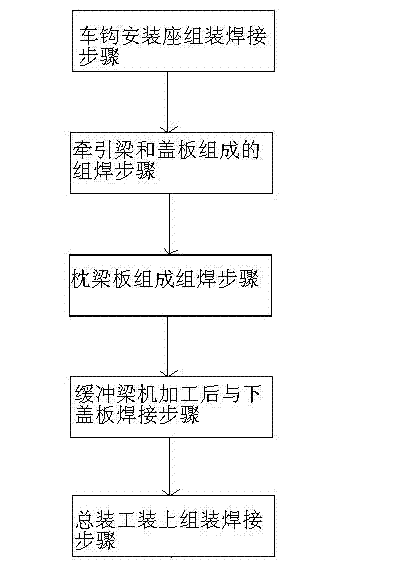

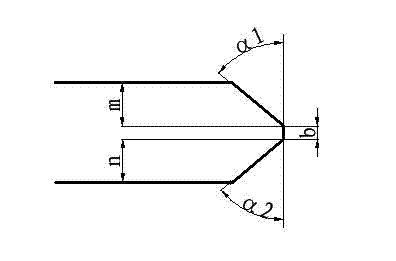

[0032] In this example, if figure 2 As shown, the above-mentioned corbel 10, traction beam 20, coupler m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com