Paint, using method thereof and multi-coating product

A technology for coatings and primers, applied in coatings, layered products, and processes for producing decorative surface effects, etc., can solve the problems of complex debugging laser engraving conditions and non-environmental protection of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

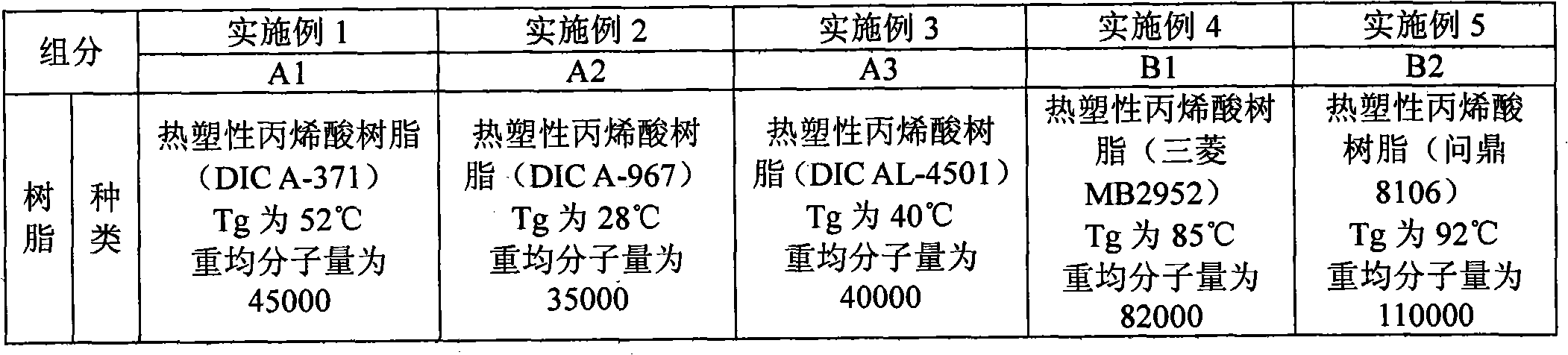

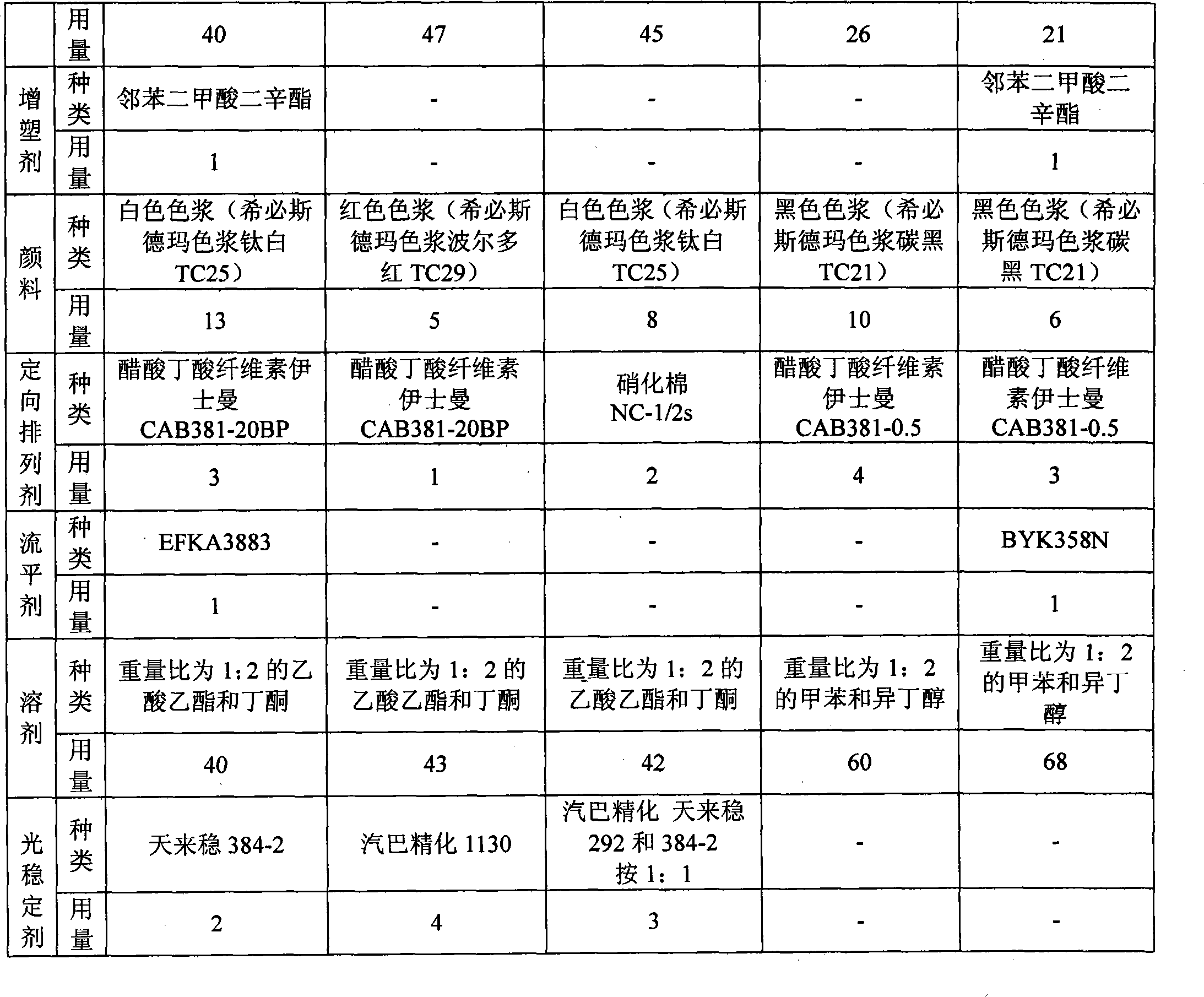

[0055] Examples 1-5 were used to prepare Primer Component A and Topcoat Component B.

[0056] The components shown in Table 1 were mixed and stirred evenly, and the obtained slurry was filtered to remove the residue therein to obtain primer components A1, A2, A3 and topcoat components B1, B2. The amounts of each component in Table 1 below are expressed in parts by weight.

[0057] Table 1

[0058]

[0059]

Embodiment 6

[0061] This example is used to illustrate the method of using the coating disclosed in the present invention and the multi-coated article.

[0062] The primer component A1 obtained in Example 1 was sprayed on the surface of a transparent plastic keyboard, and baked at 56° C. for 14 minutes to form a primer. Then, in the same manner, the topcoat component B1 obtained in Example 4 was used to form a topcoat layer to obtain a multi-coated article D1. Wherein, the thickness of the primer layer is 5um, and the thickness of the topcoat layer is 6um.

Embodiment 7

[0064] The primer component A1 obtained in Example 1 was mixed with ethanol at a weight ratio of 1:1.5, sprayed on the surface of a transparent plastic keyboard, and baked at 57° C. for 13 minutes to form a primer. Then, in the same manner, the topcoat component B2 obtained in Example 5 was used to form a topcoat layer to obtain a multi-coated article D2. Among them, the thickness of the primer layer is 6um, and the thickness of the topcoat layer is 7um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com