Engine control parameter adjustment method

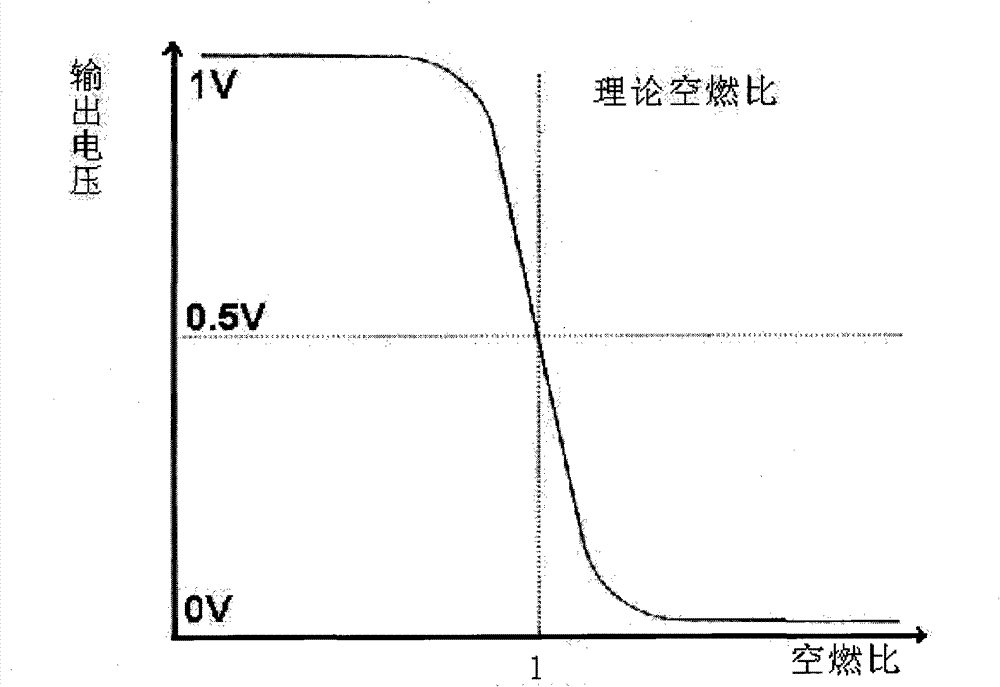

A technology of control parameters and adjustment methods, applied in engine control, machine/engine, electrical control, etc., can solve the problems of inability to obtain high-precision target data, difficulty in meeting precision requirements, high manufacturing costs, etc., and achieve low hardware requirements , achieve the effect of low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

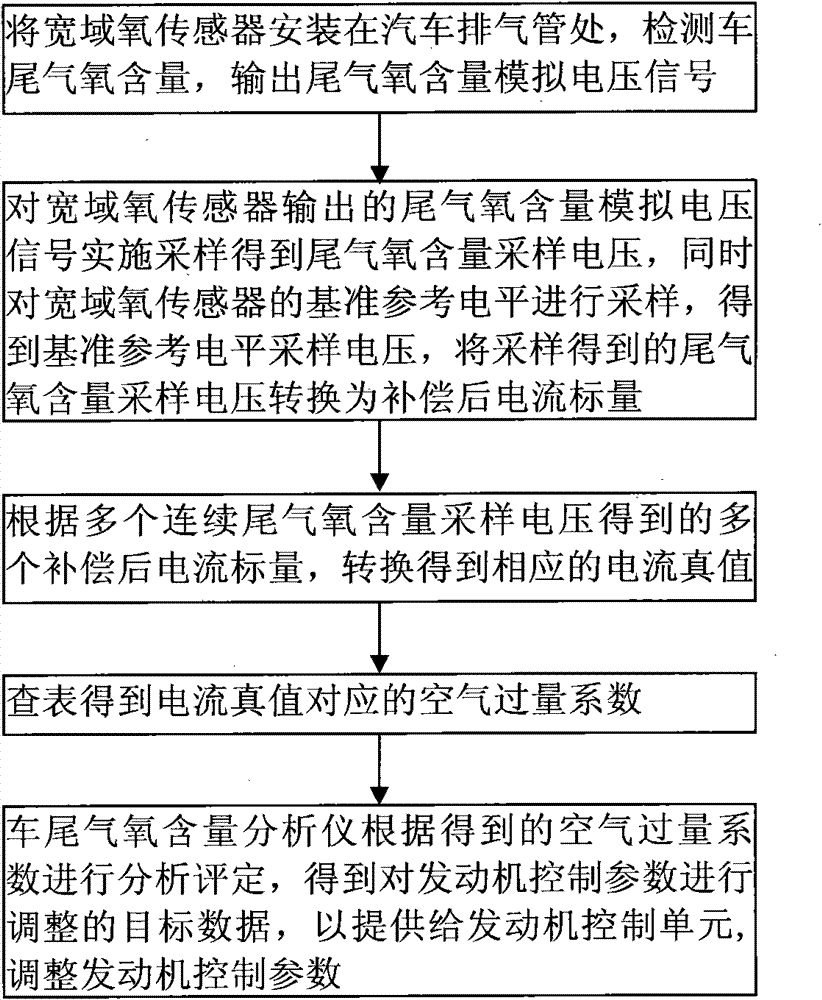

[0027] An embodiment of the engine control parameter adjustment method of the present invention is as follows: figure 2 shown, including the following steps.

[0028] 1. Install the wide-area oxygen sensor at the exhaust pipe of the car to detect the oxygen content of the exhaust gas and output the analog voltage signal of the oxygen content of the exhaust gas.

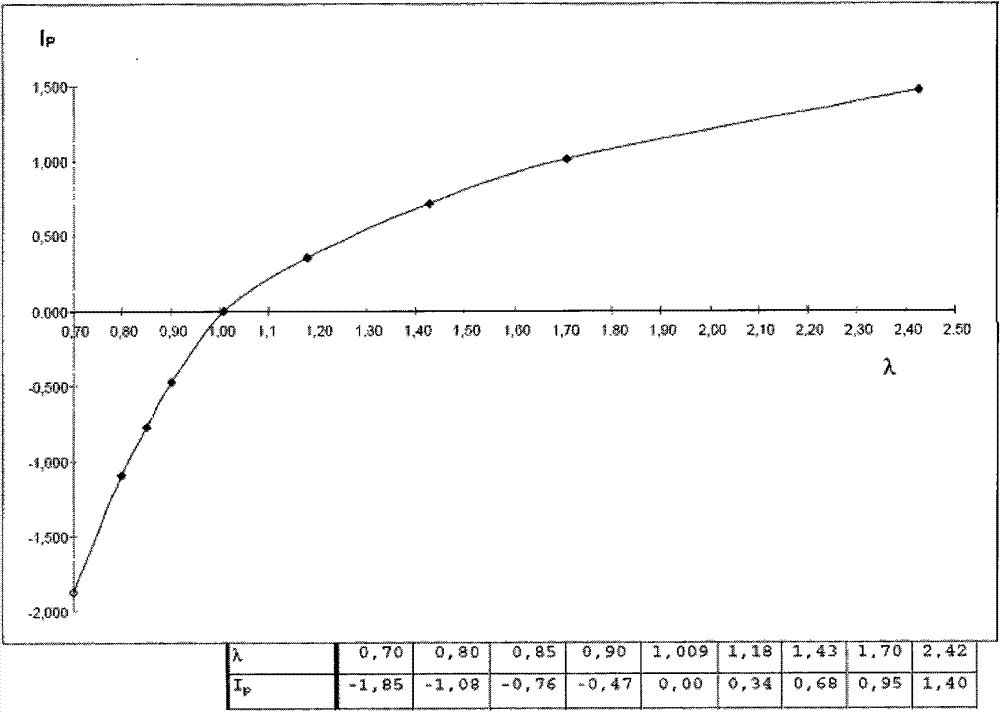

[0029] 2. Accurately sample the exhaust oxygen content analog voltage signal output by the wide-area oxygen sensor to obtain the exhaust oxygen content sampling voltage U A1 , and at the same time sample the base reference level of the wide-area oxygen sensor to obtain the base reference level sampling voltage U A2 , the exhaust oxygen content sampling voltage U obtained by sampling is obtained by the following formula A1 Converted to a compensated current scalar,

[0030] I p 2 = ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com