Cladding hinging machine

A hinge and cladding technology, applied in the field of hinges, can solve problems such as inconvenient use, inability to support, product impact damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

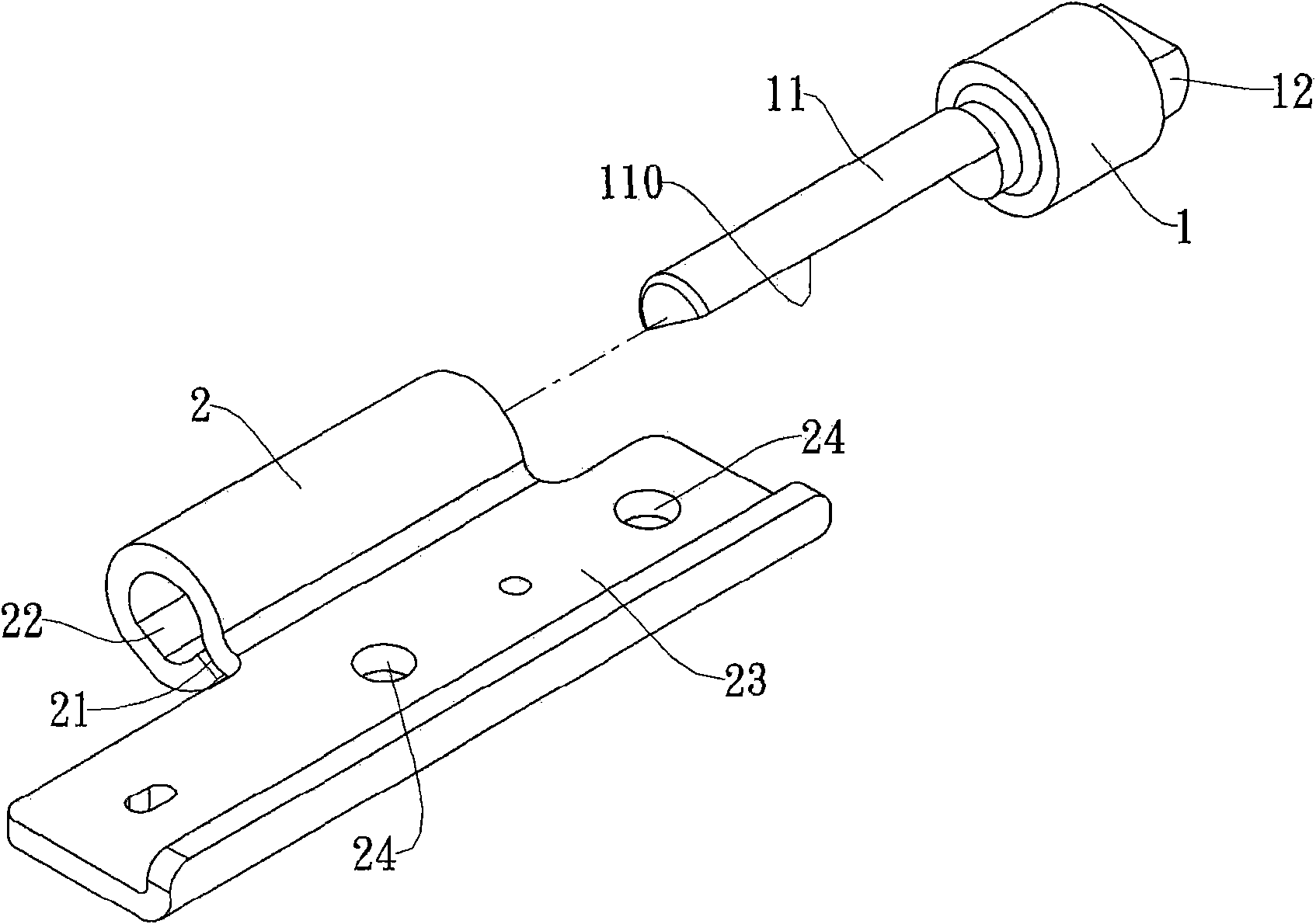

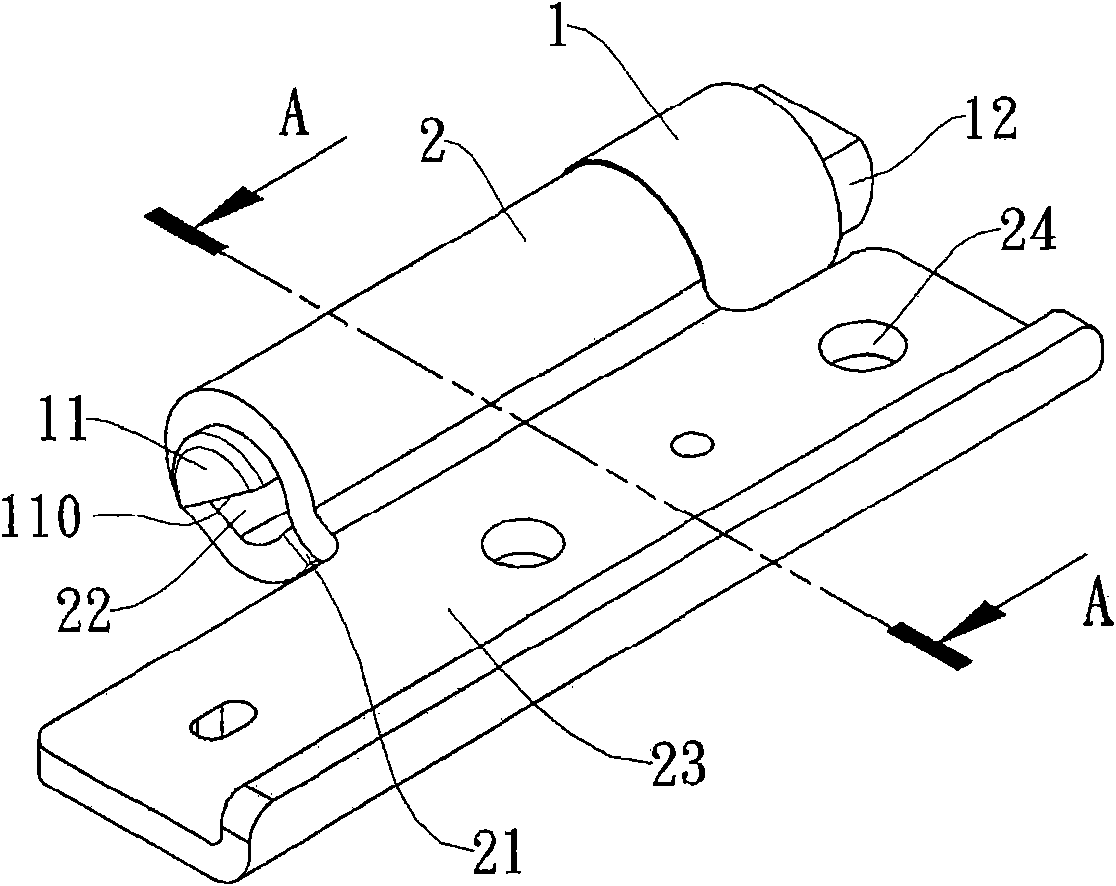

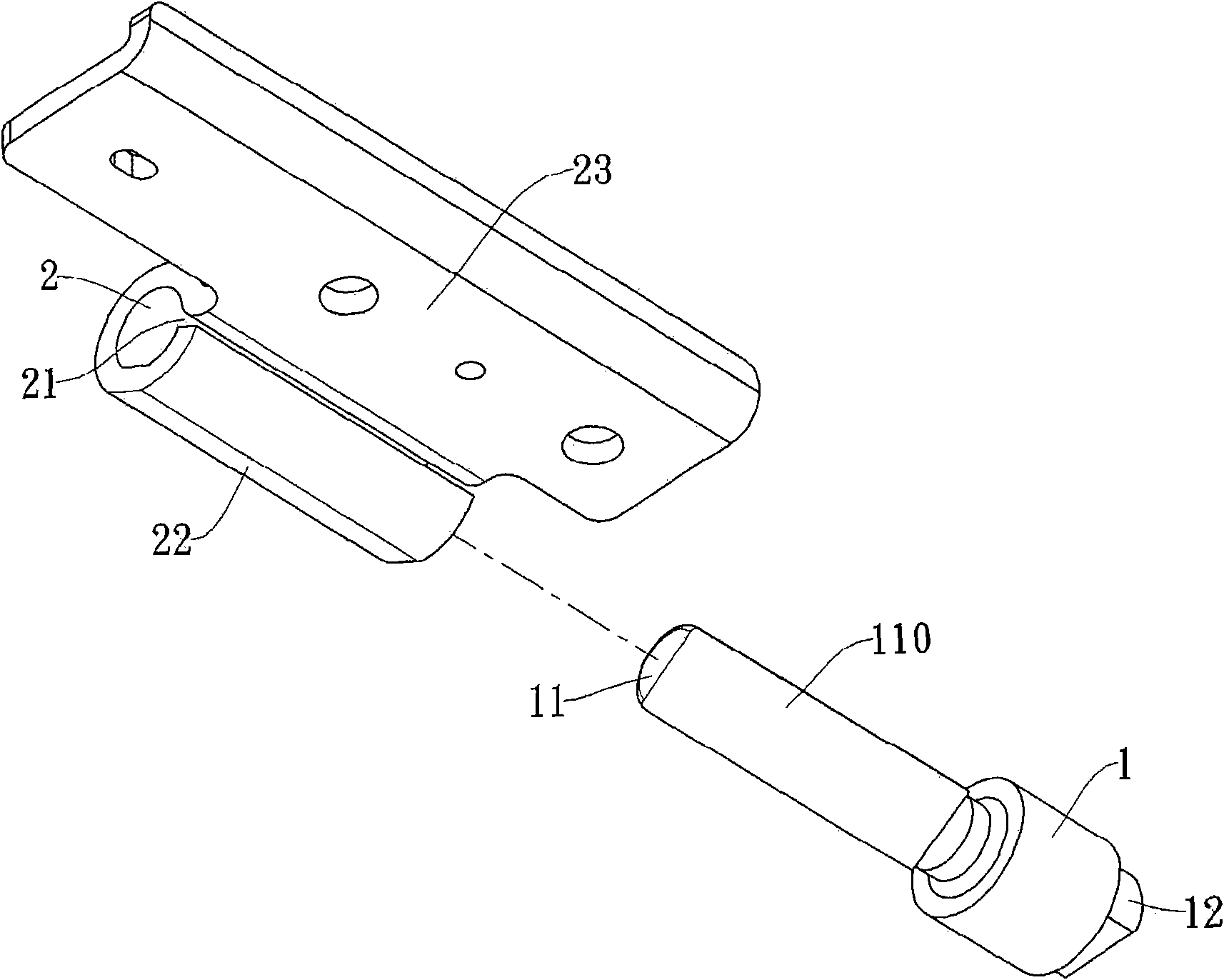

[0029] See Figure 1-Figure 4 , which are the exploded view of the parts, the three-dimensional combined view, the exploded bottom view of the parts and the A-A sectional view of the first embodiment of the present invention. The covered hinge device of the present invention includes a mandrel 1 and a cladding member 2, the mandrel 1 has a shaft 11, the shaft 11 is provided with a cut surface 110, and is non-circular, and one end of the mandrel 1 is provided with a joint 12, Used to combine and fix the body of the electronic device. The covering member 2 is sheathed on the shaft 11 and has an axial opening 21 to make it elastically expandable in the radial direction. The cladding 2 forms a plane 22, the distance from the plane 22 to the centerline of the cladding 2 is smaller than the inner radius of the cladding 2, and the width of the plane 22 is smaller than the width of the cut surface 110 of the shaft 11, so that the plane 22 does not contact the cut surface 110. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com