Falling film evaporator

A technology of falling film evaporator and distribution head, which is applied in evaporator accessories, evaporation, evaporator adjustment/control, etc. It can solve the problem that the conical distribution head cannot stick to the tube wall, the life of the liquid pipeline is short, and the heat dissipation of the distribution head is uneven. problems, to avoid uneven heating, prolong life, and facilitate the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This example illustrates the specific structure of the falling film evaporator of the present invention.

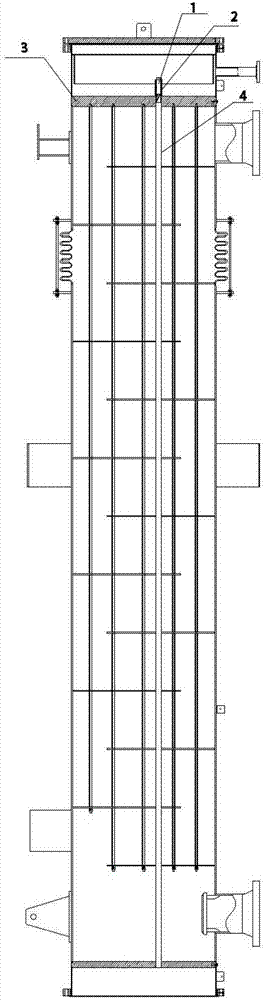

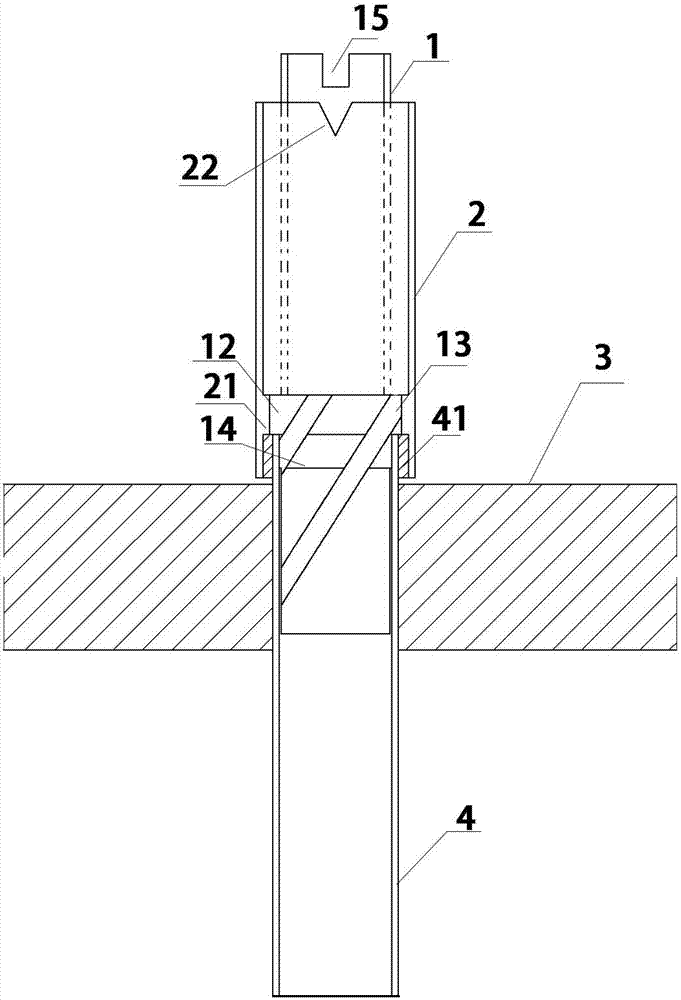

[0026] Such as Figure 1-6 The falling film evaporator shown includes a distribution head 1, a pipe sleeve 2, a tube plate 3, a tube 4 and an externally threaded tube 41 provided outside the upper end of the tube 4;

[0027] The tube plate 3 is provided with several through holes, the tube array 4 is inserted into the through hole and connected with the tube plate 3, and the upper end of the tube array is provided with an externally threaded tube 41;

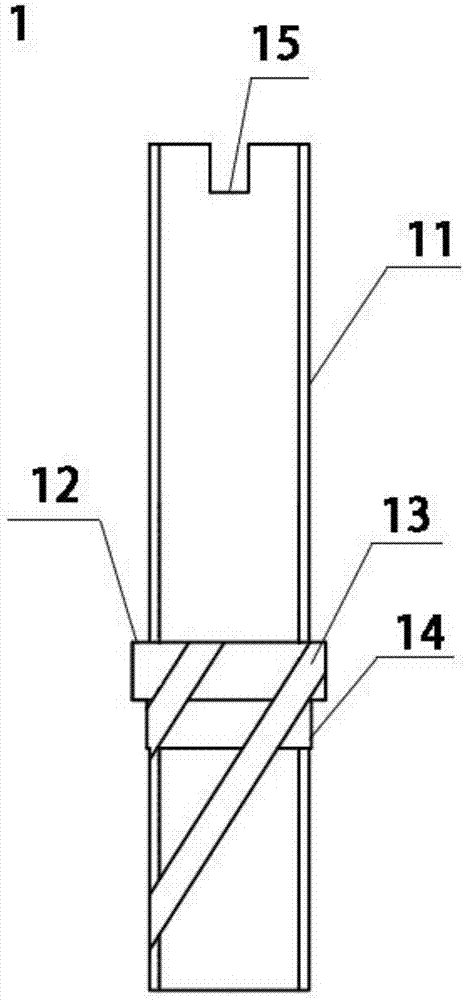

[0028] The specific structure of distribution header 1 is as follows: Figure 3-5 As shown, the main body of the distribution head 1 is a hollow tube 11, and the top of the hollow tube 11 is provided with several rectangular openings 15; The body of the hollow tube 11 is arranged as a ring-shaped protrusion; the second boss 14 is also provided below the boss 12, and the second boss 14 is arranged around the body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com