Assembly-type steel trestle supported by H-shaped steel

A prefabricated, steel trestle technology, used in portable bridges, bridges, bridge parts, etc., can solve the problems of poor firmness, difficult quality control and on-site operation, and achieve improved stability, simple and convenient installation and disassembly. , the effect of fixing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

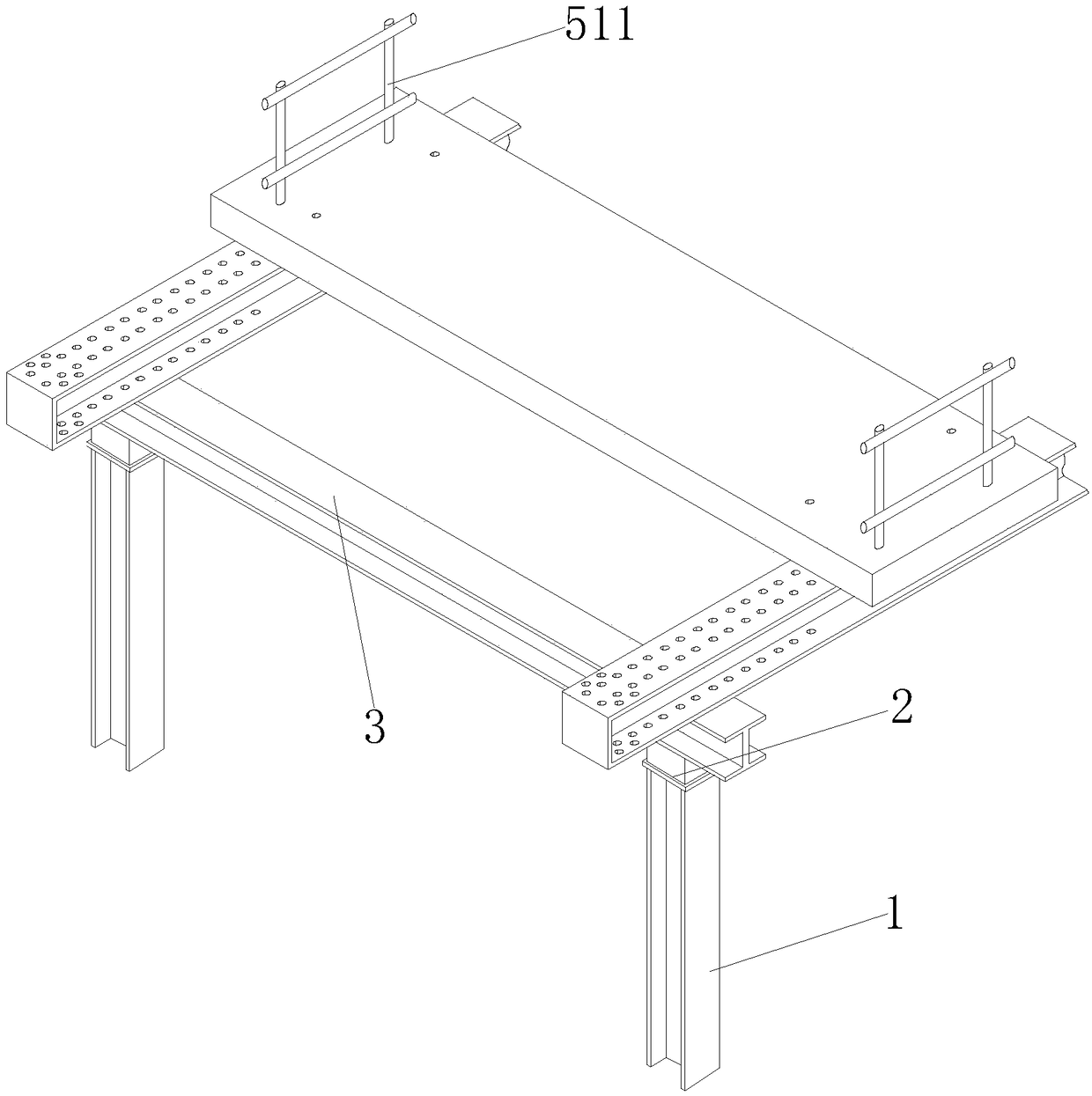

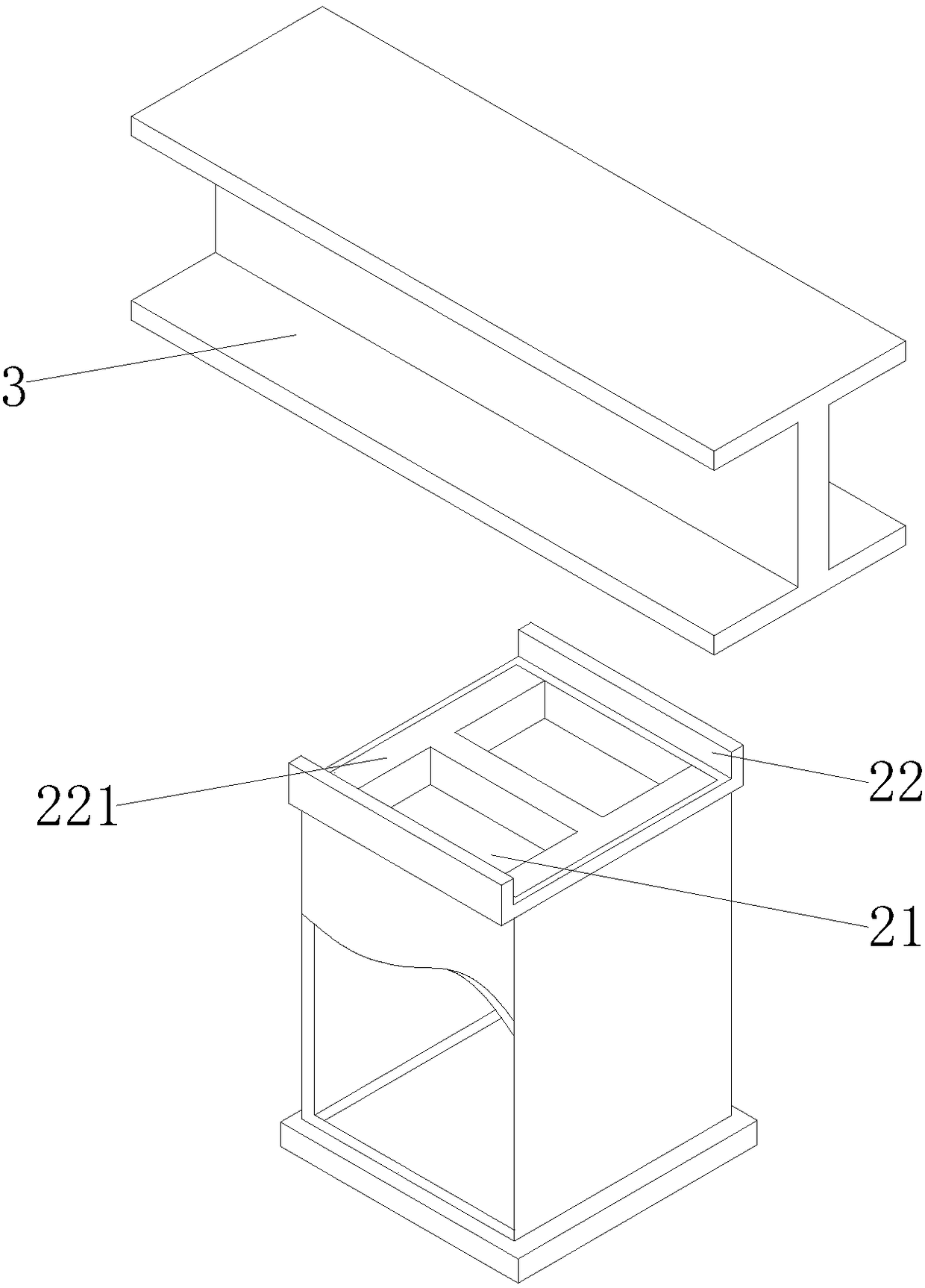

[0019] see Figure 1-3 , an assembled steel trestle bridge supported by H-shaped steel, including a plurality of H-shaped support rods 1 and bridge plates 5 fixed to the foundation, the top outer wall of the H-shaped support rods 1 is covered with auxiliary supports 2, and the auxiliary supports 2 When it is a steel member with a hollow structure, a sealing partition 21 is welded on the inner wall of the auxiliary support 2, and the sealing partition 21 divides the inner cavity of the auxiliary support 2 into two spaces, and the two sides of the upper surface of the auxiliary support 2 A vertical upward limiting plate 22 is welded symmetrically on the side, and the sealing partition 21 is closer to the limiting plate 22, and the surface of the limiting plate 22 is fixed with an H-shaped block 221 stuck in the auxiliary support 2, so that the H The block 221 is placed inside and its upper surface can be flush with the surface of the auxiliary support 2. The end surface of the H...

Embodiment 2

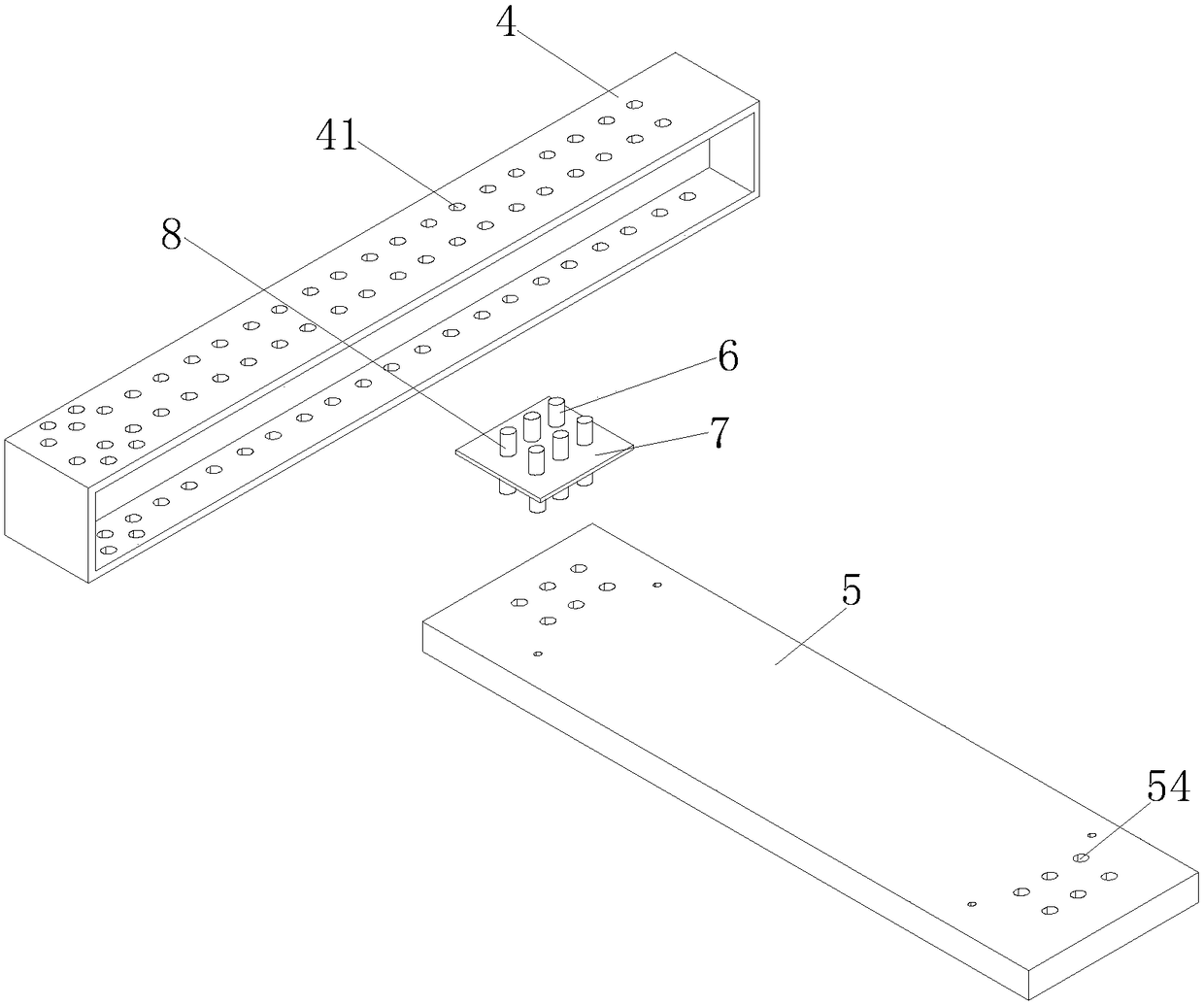

[0021] see Figure 4-5 , between a plurality of bridge plates 5, insert the through holes through the columns to improve the fixity of the bridge plates 5 on the H-shaped frame plate 4, and at the same time position the bridge plates 5 to facilitate the embedding of the dovetail tenon 9, while the adjacent bridge plates The hole positions of the dovetail semi-blind holes 53 on the side of the plate 5 are aligned. After the adjacent bridge plates 5 are put together, after the dovetail 9 is placed in the dovetail semi-blind holes 53, the bridge plates are further fixed. The firmness between 5.

[0022] To sum up: the assembled steel trestle bridge supported by H-shaped steel, the limit plate 22 blocks the two sides of the H-shaped beam 3 to prevent the H-shaped beam 3 from falling off, and improves the stability. The accumulated water is drained away, and at the same time, the water will not flow into the inner cavity of the bridge plate 5, so as to avoid oxidation after a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com