General configuration software control system

A technology of control system and configuration software, applied in the direction of comprehensive factory control, comprehensive factory control, fixed conduit components, etc. The problem of high complexity can meet the requirements of man-machine interface automatic control level, save development time, and ensure the effect of uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

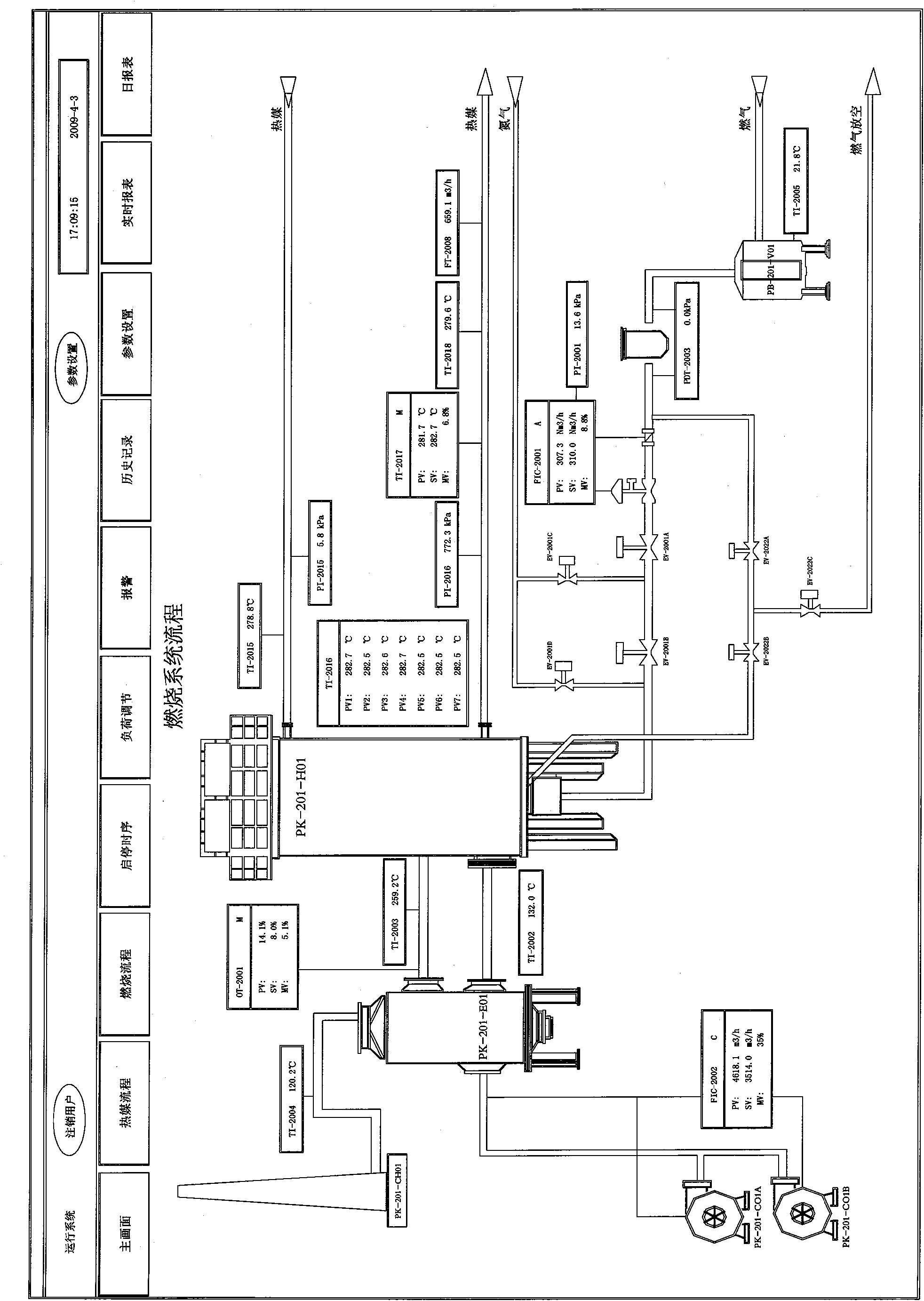

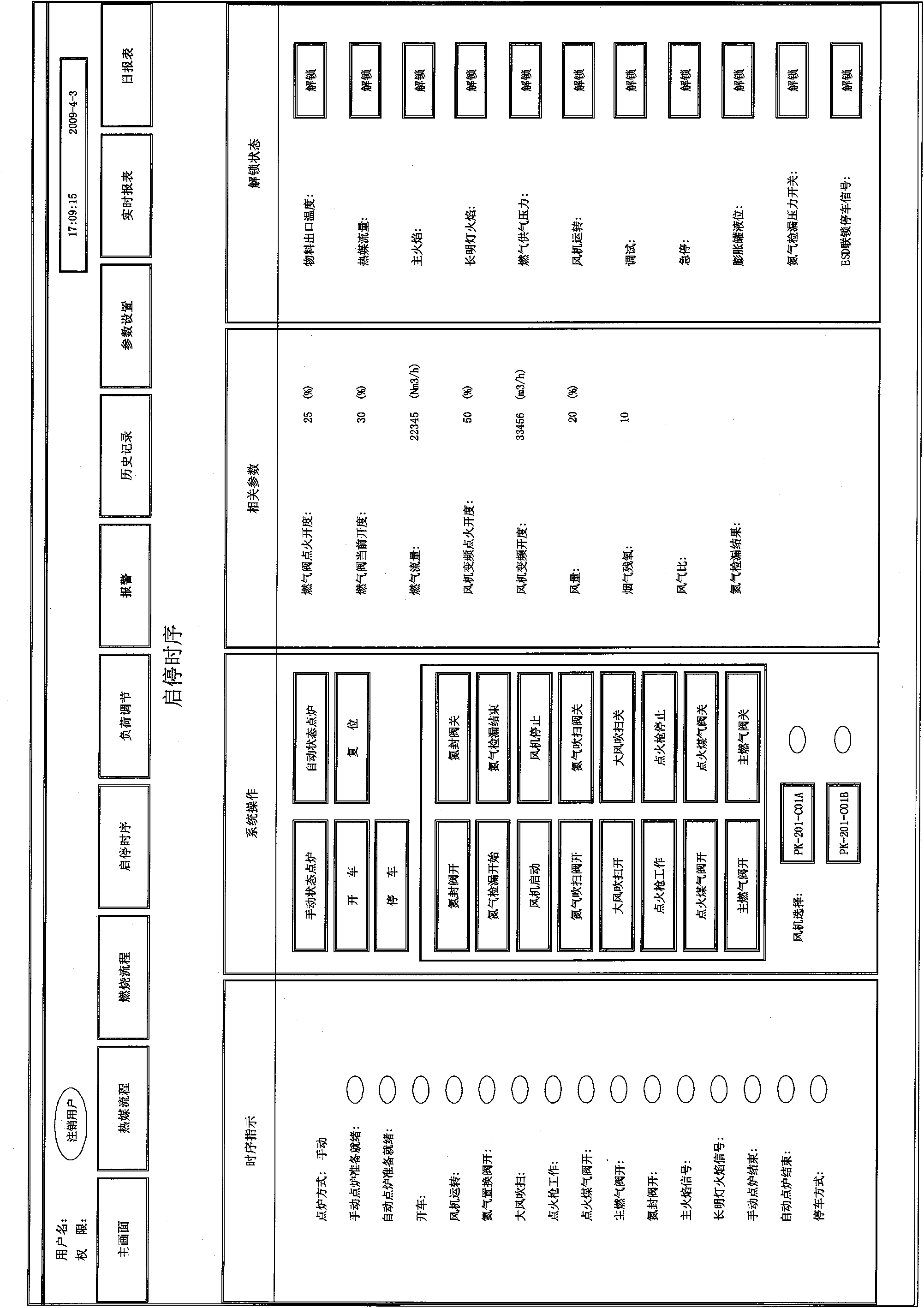

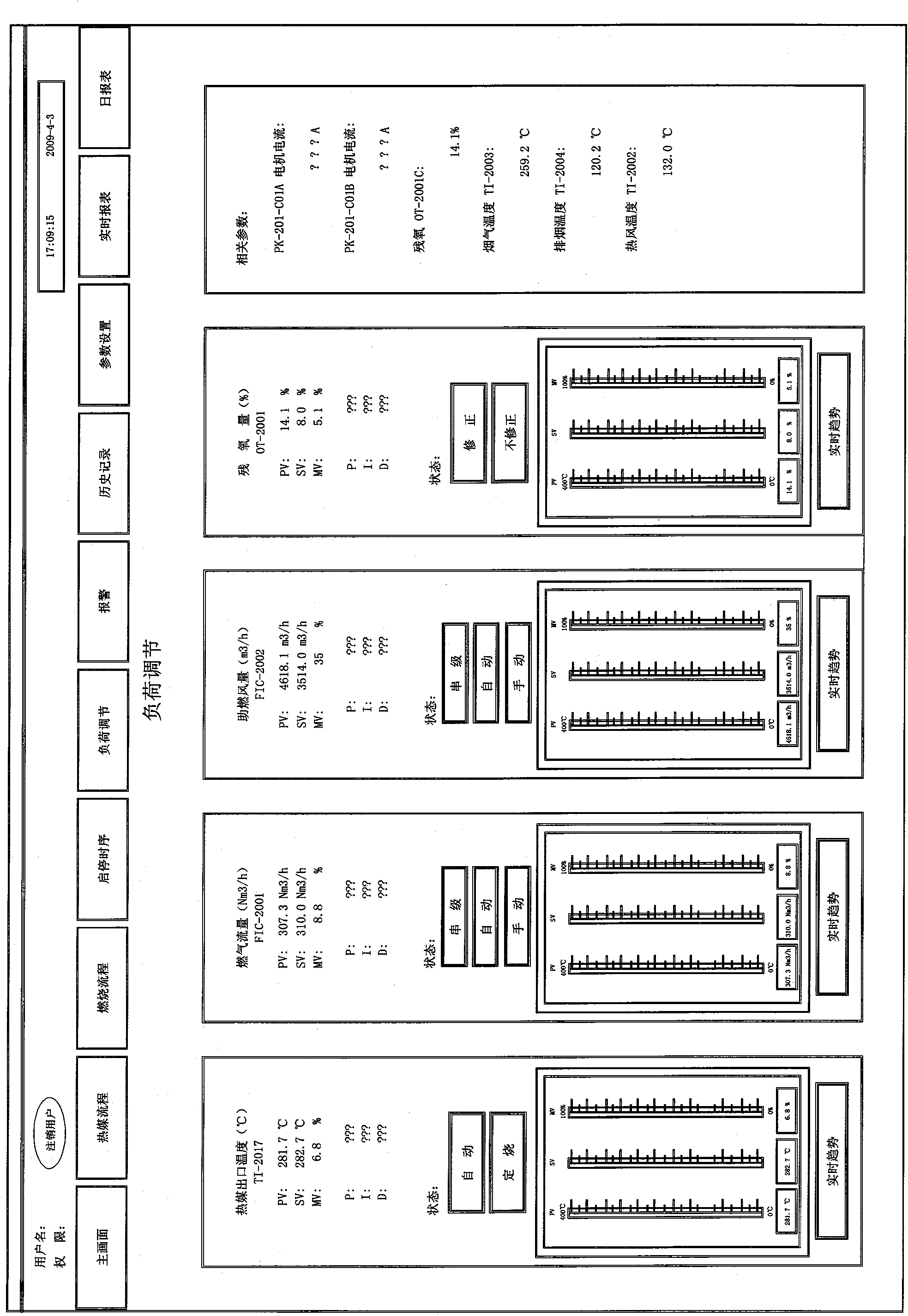

[0051] Below in conjunction with the implementation example of accompanying drawing and certain engineering project, the present invention will be further described:

[0052] like figure 1 As shown, the general configuration software control system of the present invention includes: a PID process module, a start-stop sequence module, a load regulation module, an alarm module, a historical trend module, a historical report module, and a real-time report module.

[0053] The switch between the above-mentioned main function modules and the display of the main title are completed by a special switching screen module and a main title screen module. Realize the screen switching function and the prompt function of alarm information, login information, etc. The main title screen displays the system's alarm information, user authority and login level, and can log out of the login level in real time to silence the system alarm. In the switching screen, switch between the main function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com