Direct-connected non-negative pressure water supply equipment

A technology of water supply equipment and no negative pressure, which is applied in the field of direct-connected non-negative pressure water supply equipment, can solve the problems of many pump starts and high energy consumption, and can reduce frequent starts and stops, reduce noise pollution, and reduce the number of starts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

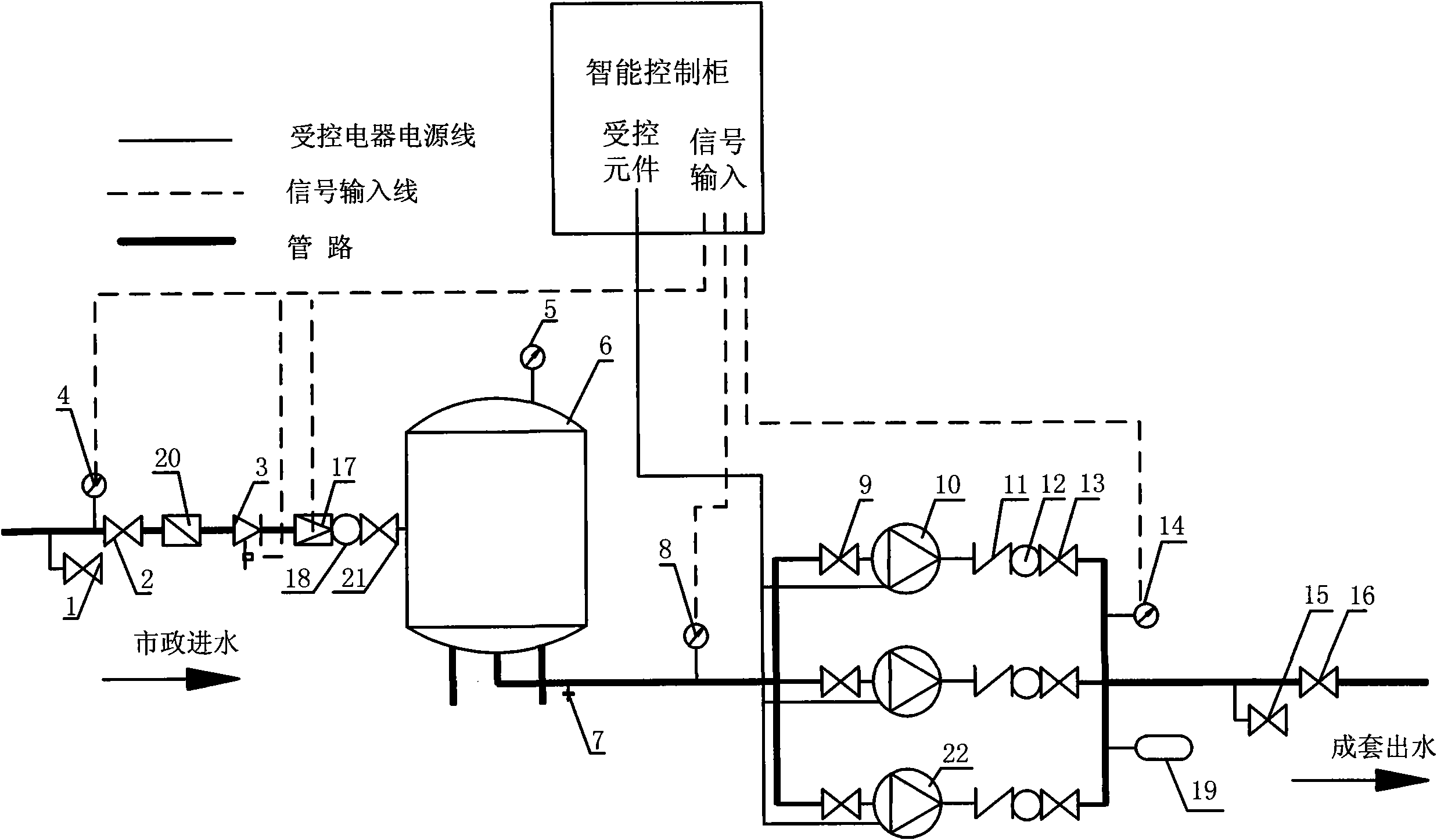

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

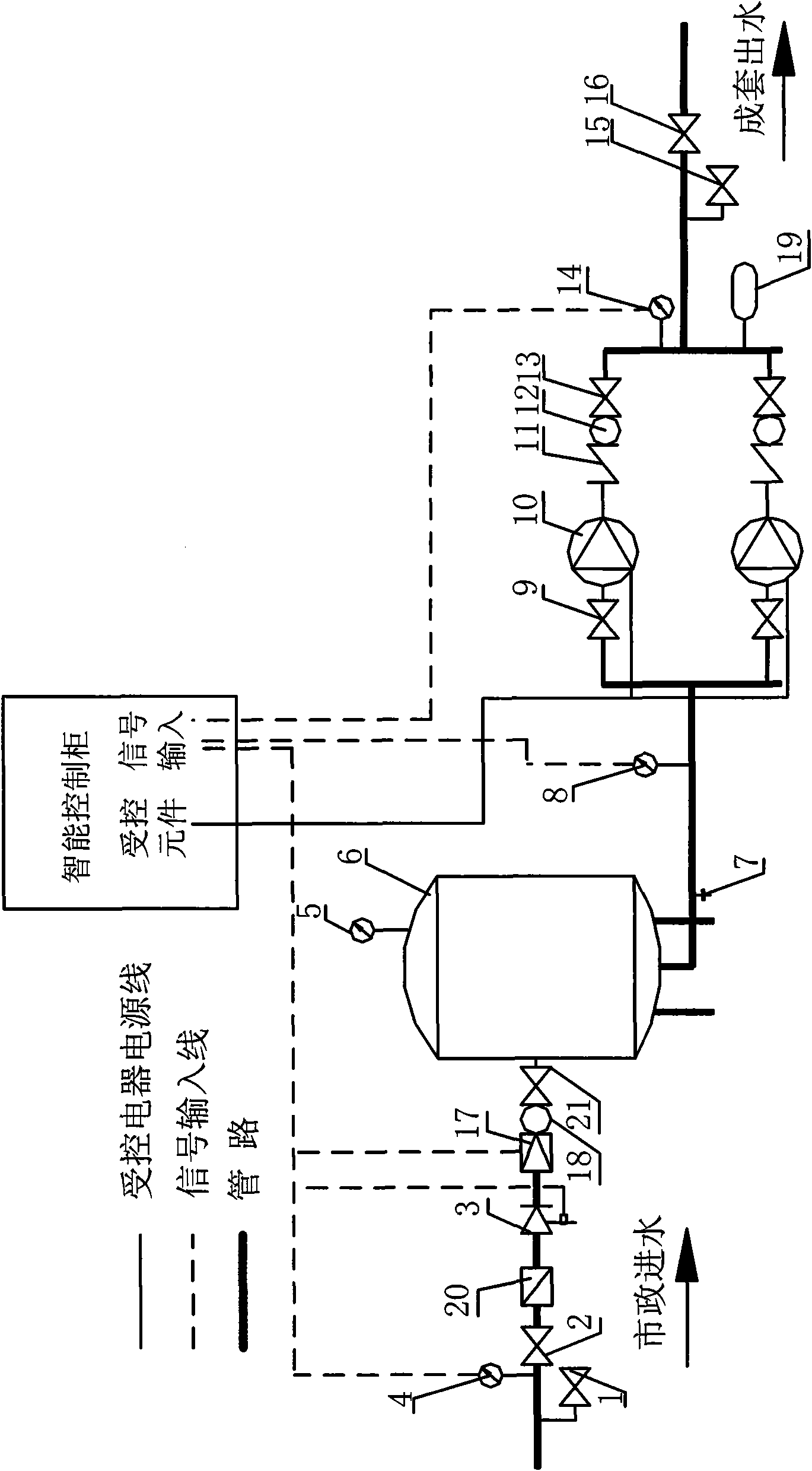

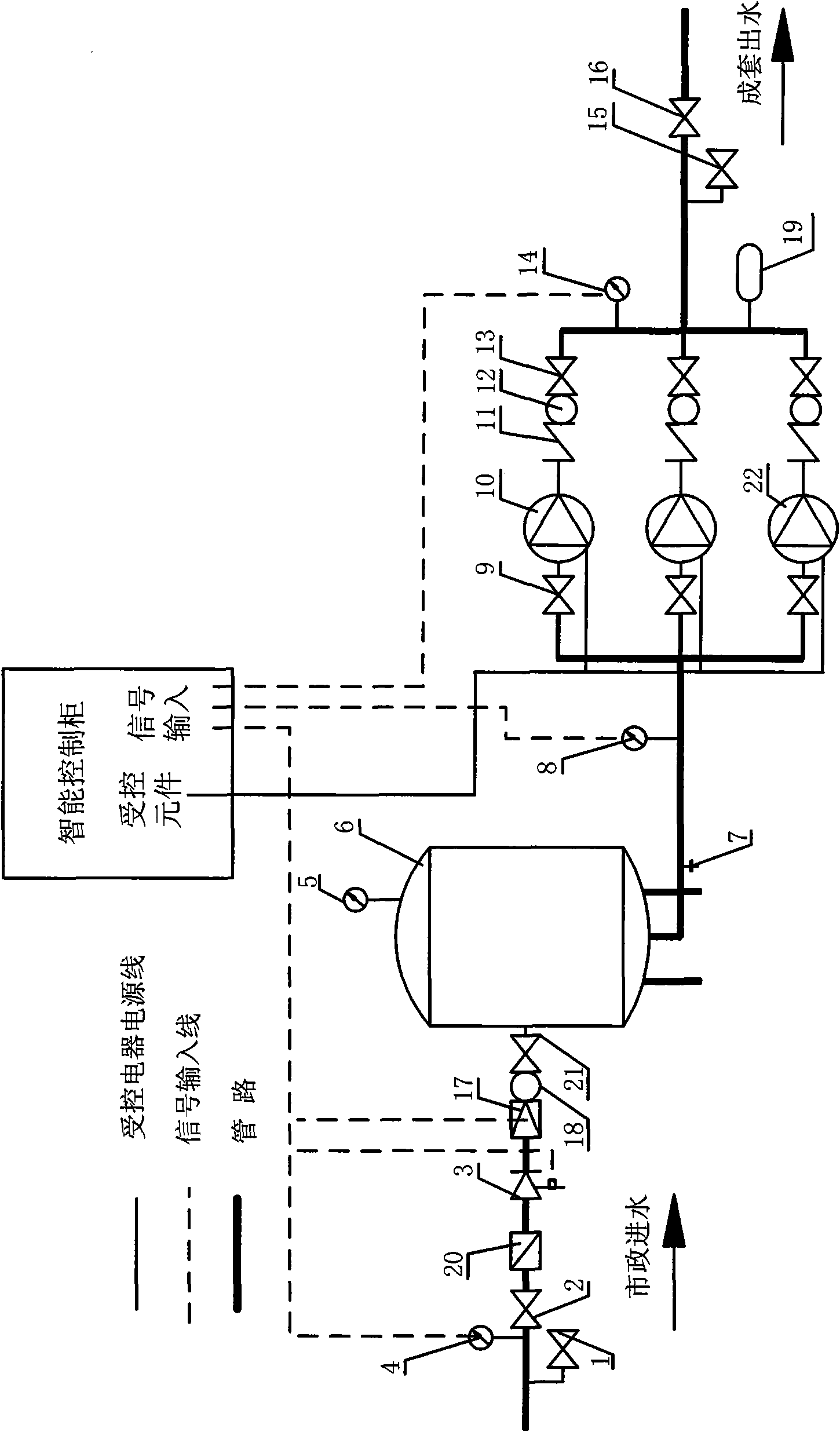

[0010] Such as figure 2 As shown, the direct-connected non-negative pressure water supply equipment of the present invention includes a water inlet drain valve 1, a water inlet butterfly valve 2, a backflow preventer 3, a water inlet pressure transmitter 4, a diaphragm three-way exhaust valve 5, and a steady flow tank 6. Drain valve 7, water inlet pressure transmitter 8, first butterfly valve 9, water pump 10, check valve 11, flexible joint 12, second butterfly valve 13, water outlet pressure transmitter 14, water outlet drain valve 15 , water outlet butterfly valve 16, flow metering device 17, flexible joint 18, air pressure tank 19, filter 20, control valve 21 and pressure stabilizing pump 22, water inlet pressure transmitter 4 is connected to water inlet drain valve 1 and water inlet butterfly valve 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com