Device for detecting and adjusting gas outlet flow of lighter

A technology for regulating devices and air flow, which is applied in the direction of combustion ignition, lighting and heating equipment, and combustion methods. It can solve the problems of large impact on lighter structure, high detection environment requirements, and complex circuit structure, so as to avoid damage to plastic parts by flames. Impact, low requirements for the detection environment, and the effect of simplifying the detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

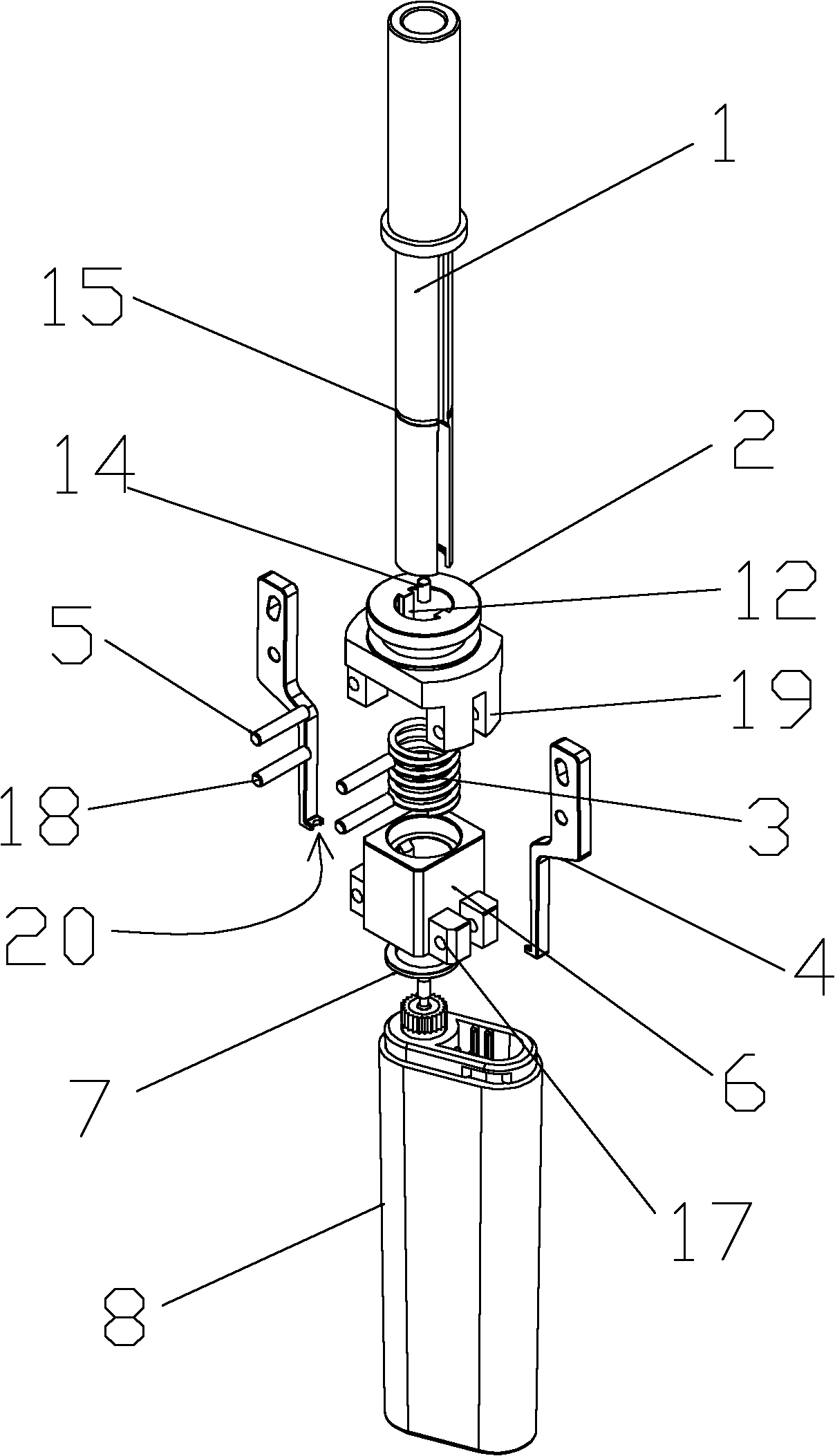

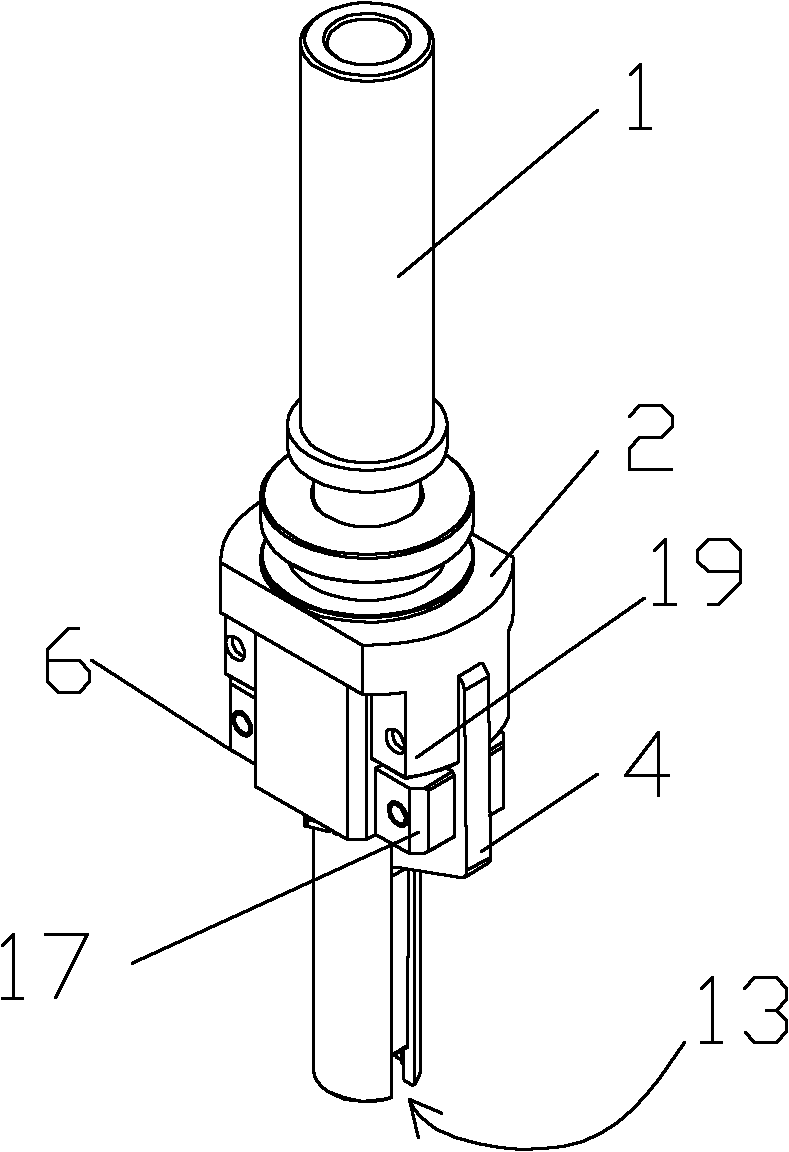

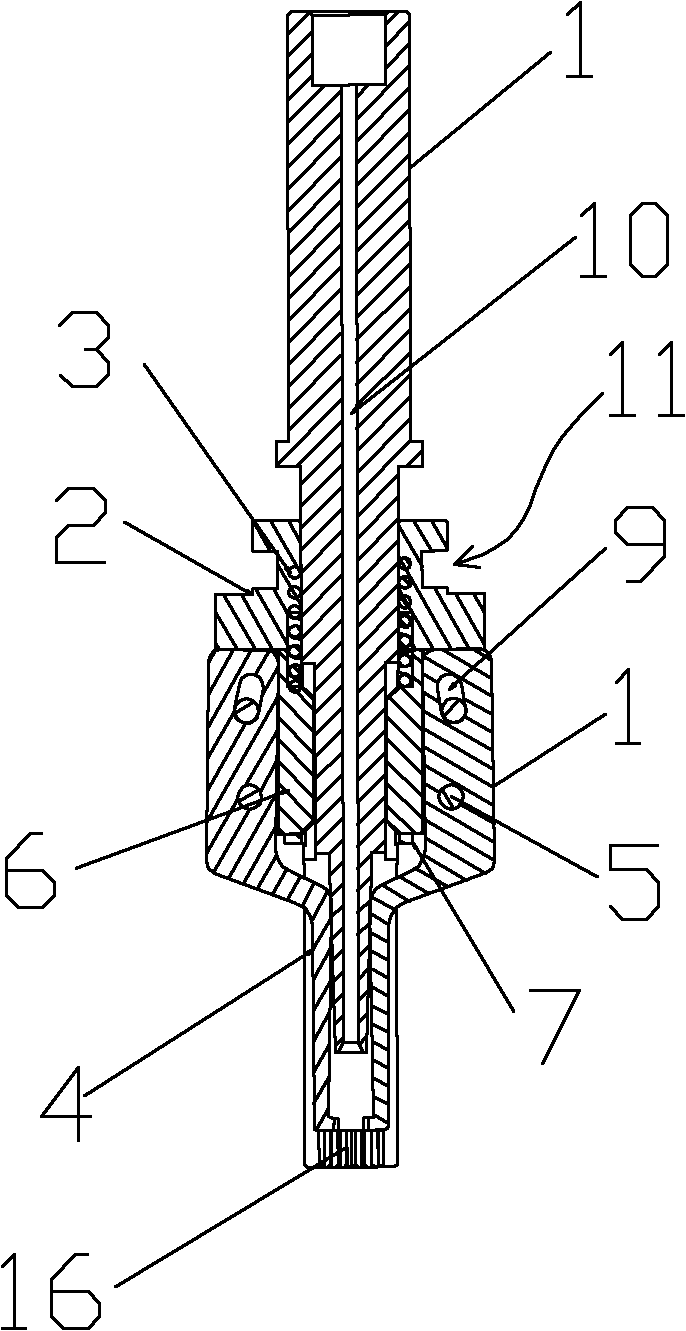

[0022] The present invention will be further described below with reference to the accompanying drawings.

[0023] like Figure 1-3 As shown, a device for detecting and regulating the outlet gas flow of a lighter described in this embodiment includes a ventilation shaft 1, a clamp fixing seat 6 sleeved on the ventilation shaft 1 and a clamp adjusting member 2, and symmetrically arranged on both sides of the clamp fixing seat 6. The two splints 4, the clamp fixing seat 6 is fixedly installed on the ventilation shaft 1; the middle part of the splint 4 is pivotally connected to the lower part of the clamp fixing seat 6 through the positioning pin 18, and the upper part of the splint 4 has an upward and inward The adjustment hole 9 provided obliquely, a movable pin 5 runs through the adjustment hole 9 to connect the upper part of the splint to the clamp adjustment part 2, and the inner side of the bottom of the splint 4 forms a clamping opening 20; the center opening of the ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com