Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

A technology of masking tape and adhesive, which is applied in the field of adhesives for high-temperature resistant masking tape and high-temperature resistant masking tape, and can solve the problem that the tape is difficult to meet the requirements of high-temperature use, poor high-temperature resistance, and degumming of circuit boards, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with embodiments:

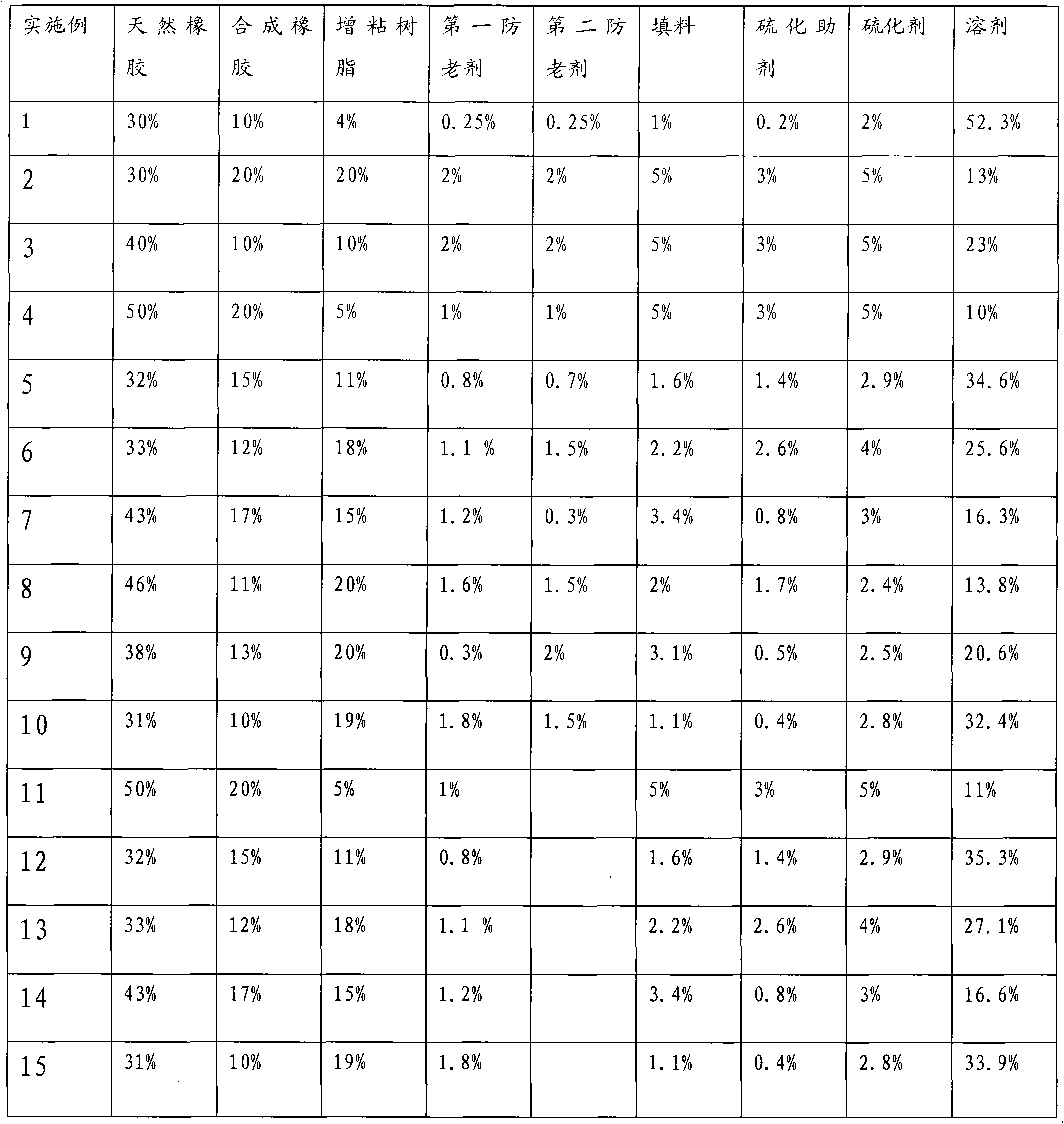

[0027] The weight percentage of each raw material in each embodiment is as follows:

[0028]

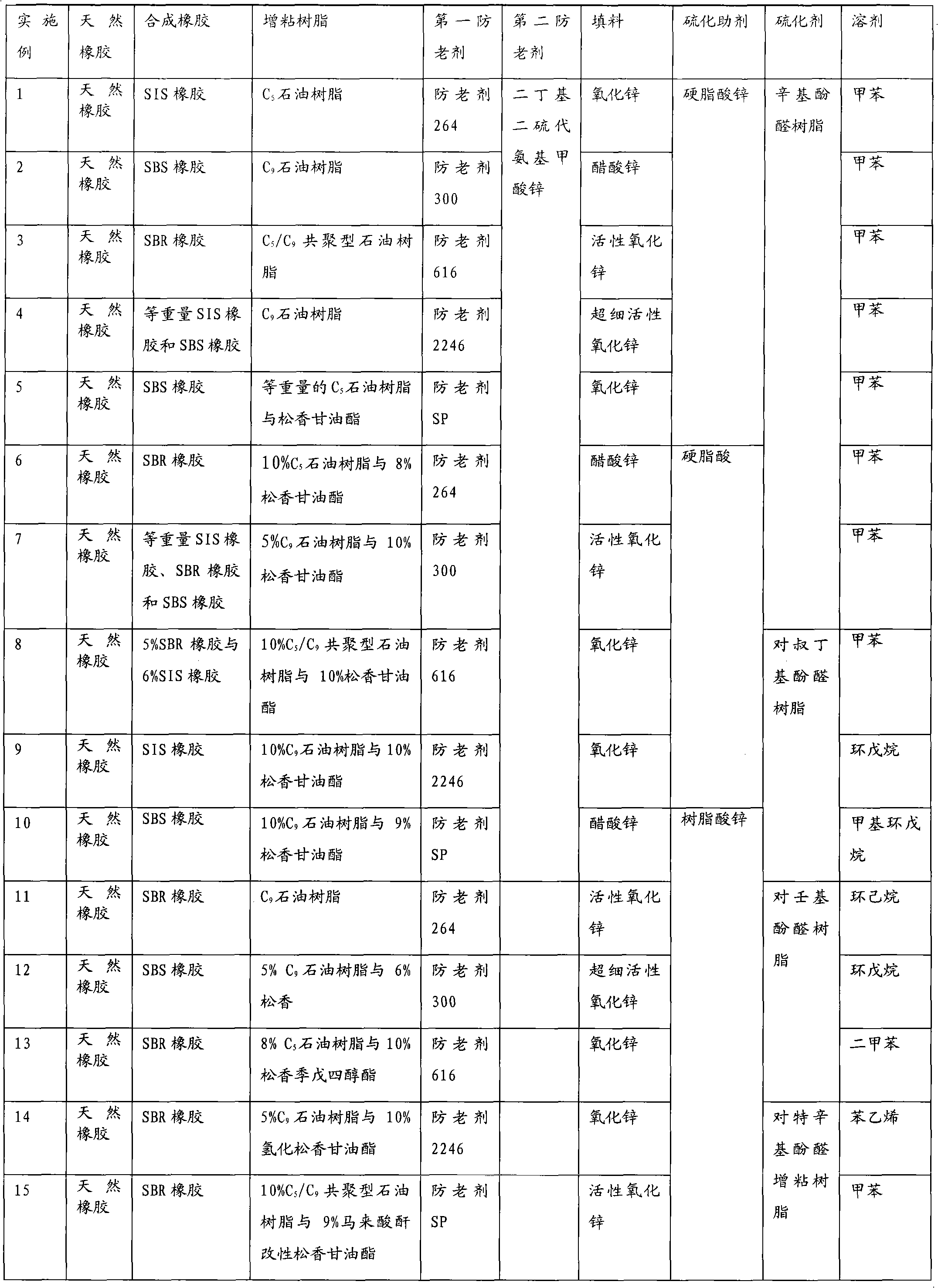

[0029] In each embodiment, the specific names of the raw materials are as follows:

[0030]

[0031] The formulas of the foregoing embodiments are produced according to the following production method: natural rubber is plasticized to a Mooney viscosity of 50-60 for use. 2. According to the formula amount, pour the solvent into the stirring reactor and start the stirring; then put in the antioxidant and filler, and stir for 15-30 minutes; put in the natural rubber and synthetic rubber, and stir for 30-60 minutes; put in the tackifying resin and stir 6 10 hours; stop stirring, cool the stirring reactor to below 45°C; put in the vulcanizing aid and vulcanizing agent and stir for 30 minutes, and stir evenly; the adhesive preparation is completed and ready for use.

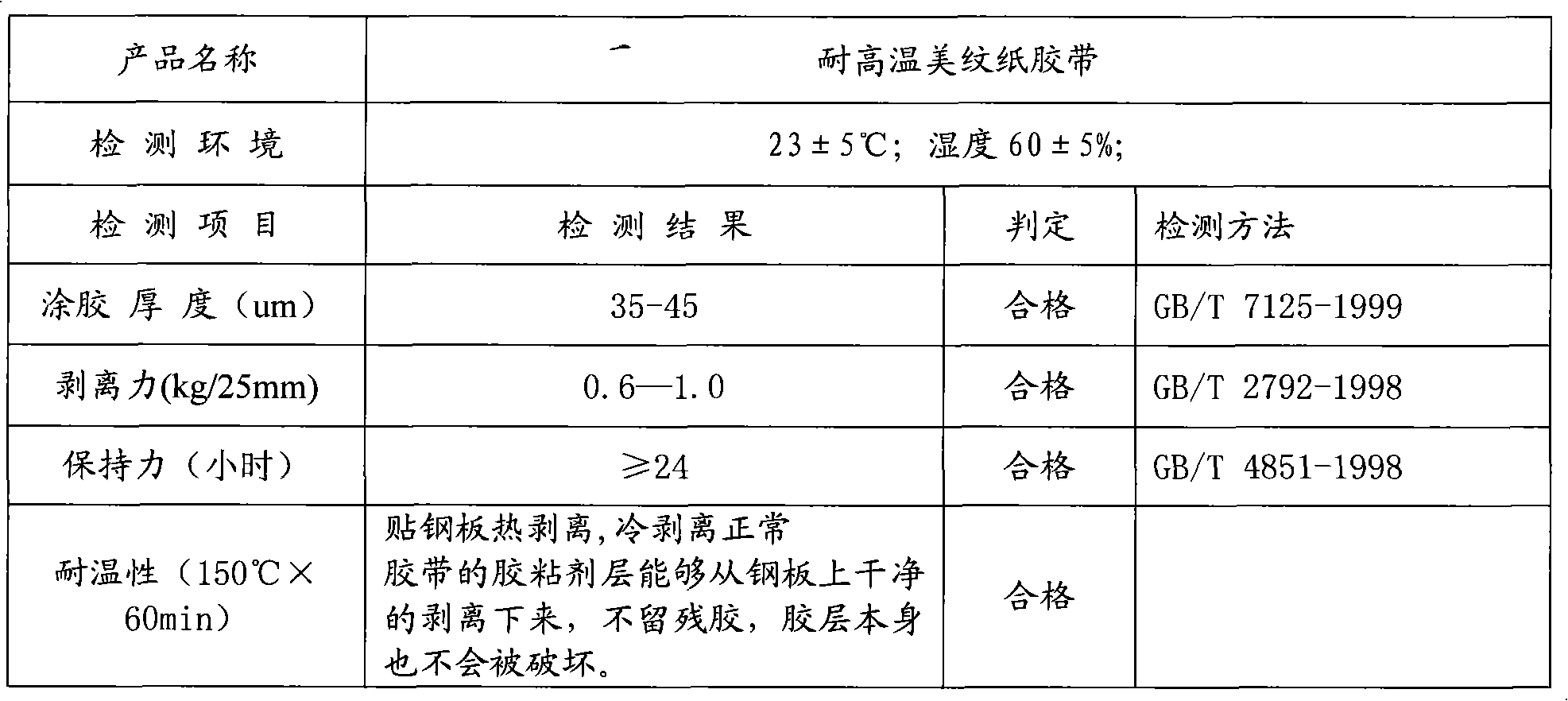

[0032] When manufacturing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com