Pole mechanical fixing structure of permanent magnet motor

A technology of mechanical fixation and permanent magnet motor, which is applied in the direction of magnetic circuit shape/style/structure, synchronous machine, electrical components, etc., can solve the problem of unreliable positioning of rotor magnetic poles, and achieve easy implementation, accurate installation and positioning accuracy, and reduce Effect of Installation Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

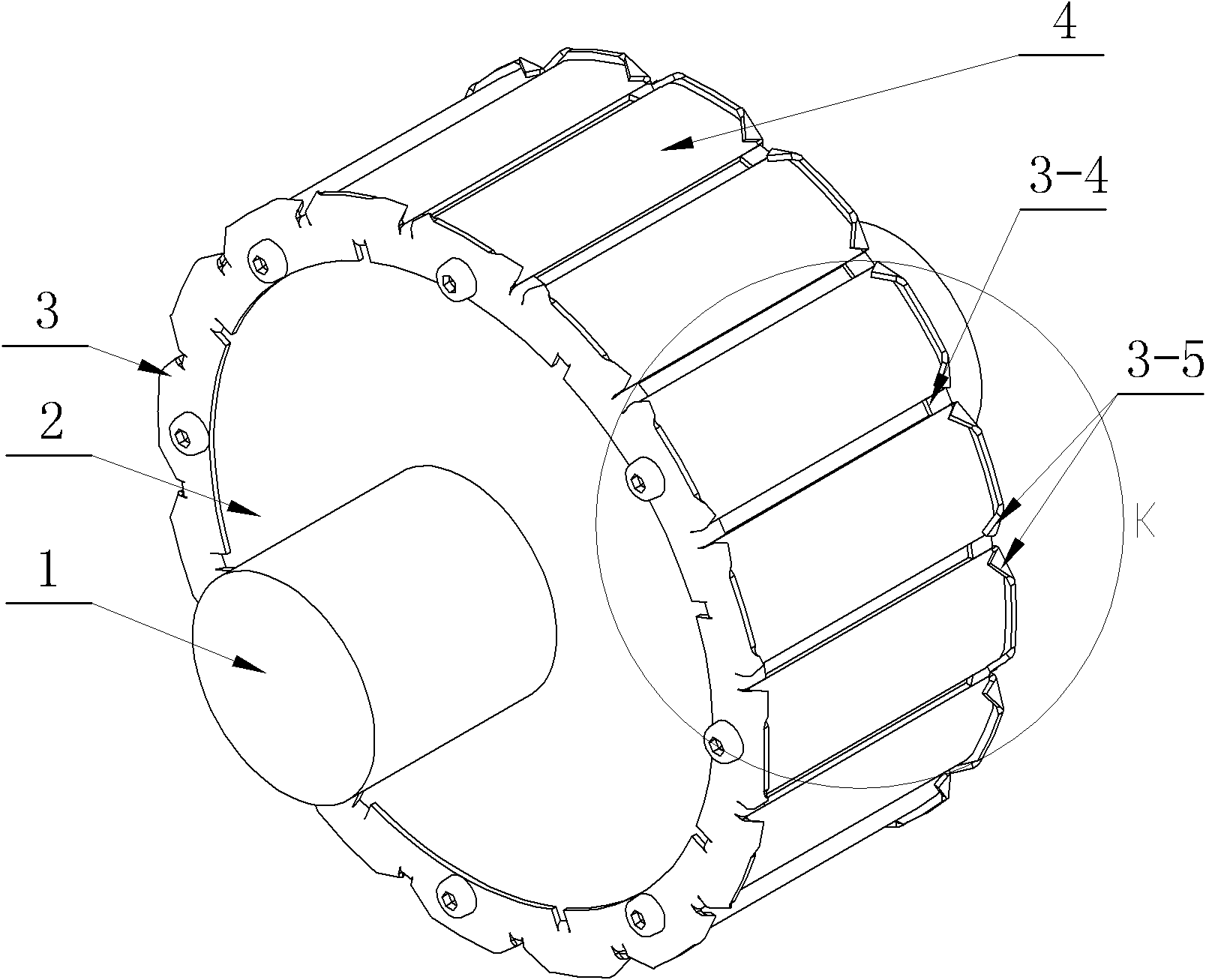

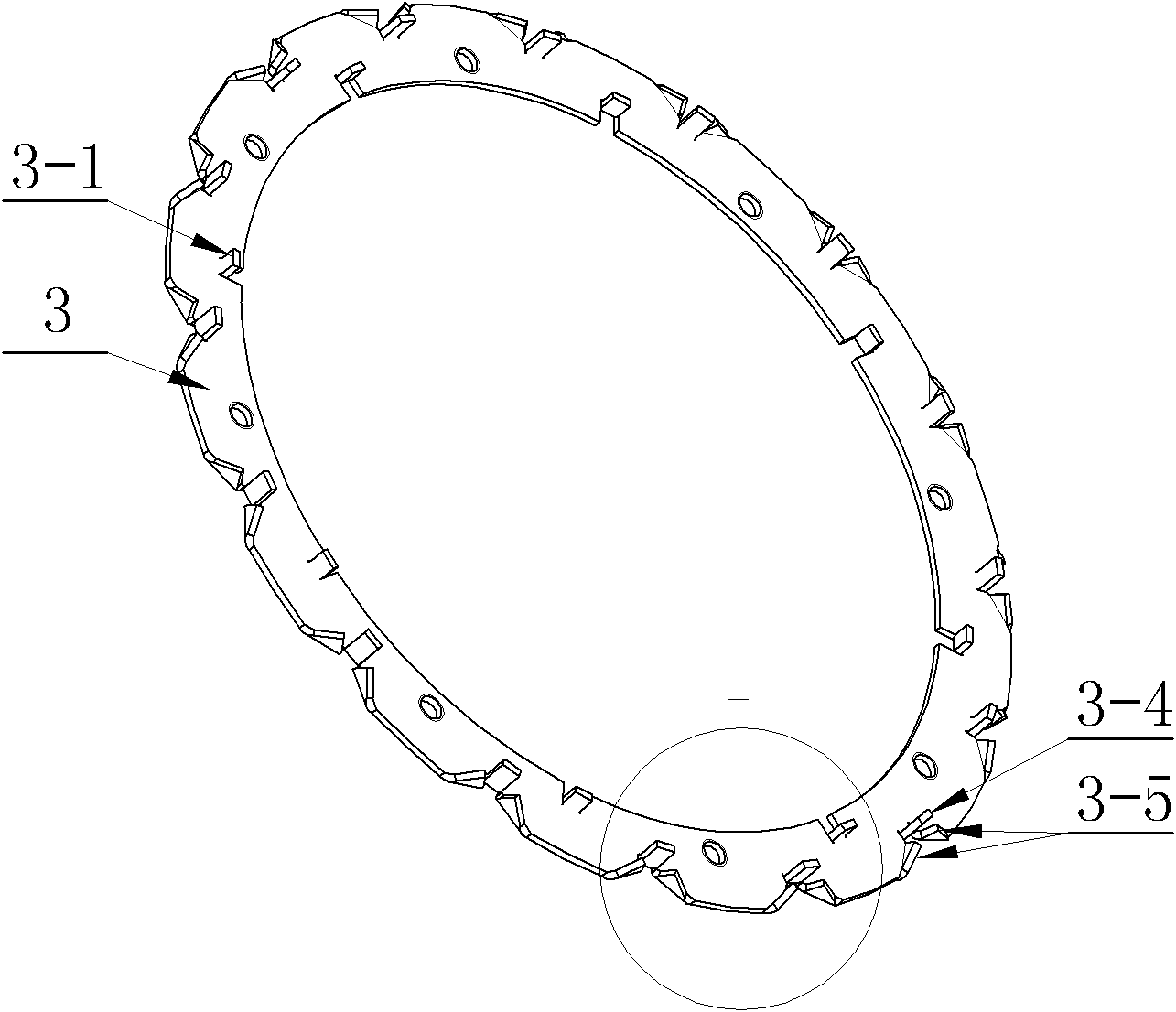

[0016] Specific implementation mode one: the following combination figure 1 and Figure 4 Describe this embodiment, this embodiment includes a rotating shaft 1 and a rotor yoke 2, the rotor yoke 2 is sleeved on the outer circular surface of the rotating shaft 1, it also includes two annular rotor pressure plates 3 and P magnetic poles 4,

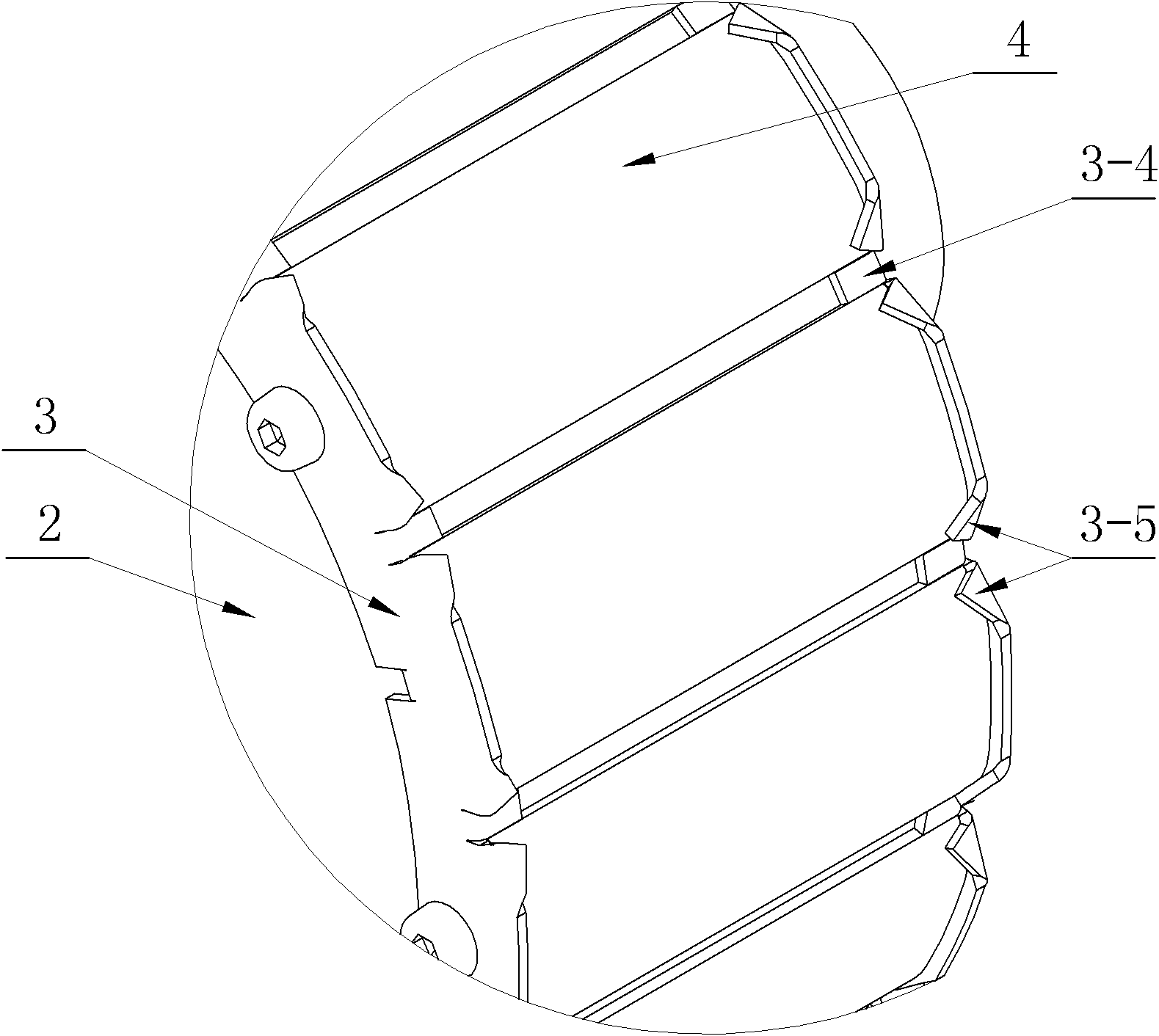

[0017] Two annular rotor pressure plates 3 are respectively fixedly connected to both ends of the rotor yoke 2, and form grooves with the outer surface of the rotor yoke 2, and P magnetic poles 4 are evenly distributed in the grooves along the circumferential direction of the rotor.

[0018] P number of limit pins 3-4 and P pair of convex pins 3-5 are respectively punched on the outer ring surface of each annular rotor pressure plate 3, and the P number of limit pins 3-4 are evenly distributed on the annular rotor pressure plate On the outer circumference of 3, the P limit pins 3-4 on the two annular rotor pressure plates 3 are arranged opp...

specific Embodiment approach 2

[0023] Specific implementation mode two: this implementation mode is a further description of implementation mode one,

[0024] The annular rotor pressure plate 3 is an integral structure or a spliced structure.

[0025] Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com